13X-HP Molecular Sieve

Chemequip’s 13X molecular sieve refers to the sodium molecular sieve with X-type crystal structure, which is an alkali metal aluminosilicate. 13X molecular sieves can adsorb molecules with a critical diameter not more than 10A.

Chemequip13X-HP molecular sieve is specially developed for on-site production of oxygen under the conditions of ultra-air pressure swing adsorption process.

HOT SELLING Molecular Sieve

Molecular Sieve 13X-HP Application

- Industrial gas drying

- Purification of feed gas of air separation device (simultaneous removal of H₂O and CO₂)

- Remove hydrocarbons from the feed gas of the air separation device

- Adsorption of molecules likes certain aromatic hydrocarbons and branched chain hydrocarbons.

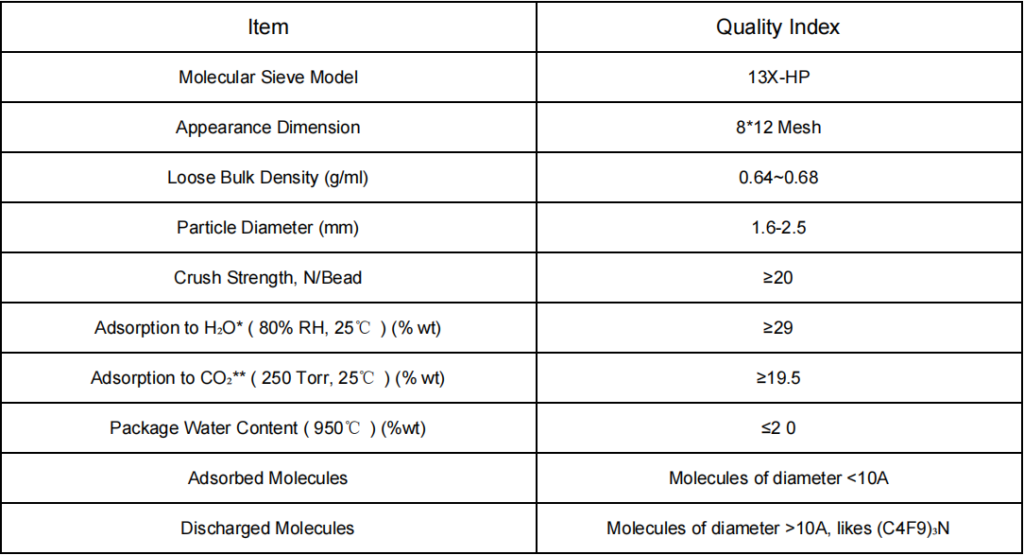

Molecular Sieve 13X-HP Technical Specification

*The amount of water adsorbed by the activated adsorbent per 100g at a pressure of 17.5 mm Hg and temperature of 250℃.

** The amount of CO₂ adsorbed per 100g of activated adsorbent at a pressure of 250 mmHg and a temperature of 250℃

Molecular Sieve 13X-HP Packing

- PE Carton 25/50kg

- Ton/half ton bag package

- Iron drum, net weight 125/135/140kgs

- Customized package by customer requirements

Molecular Sieve 13X-HP Storage

- Room temperature; indoor humidity not more than 90%

- Avoid water, acid and alkali; isolate air and sealed preservation.

Molecular Sieve 13X-HP Regeneration

Chemequip 13X-HP molecular sieve can be purged and regenerated by increasing the temperature, regeneration (dehydration) degree depends on the humidity and temperature of the purging gas.

Water Removal: Heat dry gas such as nitrogen, air, hydrogen, saturated hydrogen carbide to 150-320℃, then pass it into the molecular sieve bed under the pressure of 0.3-0.5 kgf/m2 for 3-4 hours, and then pass the dry cold gas into the adsorber for 2-3 hours, isolate the air and cool it to room temperature.

Organic Removal: Replace the adsorbent from the molecular sieve by vapor and then heat or pass into hot vapor or inert gas at the in 200-350℃, not use gases that produce explosive mixtures by contact with the adsorbent.

Gas Removal: Reduce the pressure.