Are you tired of moisture problems or impure gas streams in your operations? I was once in the same spot, but 13X molecular sieve changed everything for me.

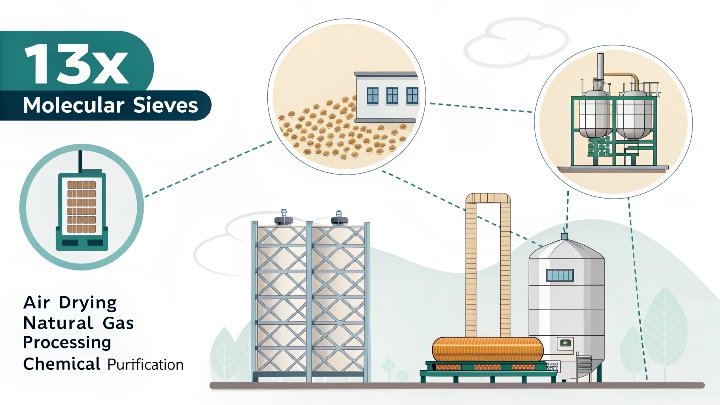

13X molecular sieve is a sodium X-type crystal structure made of alkali metal aluminosilicates. It has an effective pore size of about 10Å and can capture water, hydrogen sulfide, carbon dioxide, and other molecules. It helps refineries remove moisture and impurities, boosts air separation processes, and even supports medical oxygen production.

I still remember when I first used it in a project. I was amazed by its power to remove water and carbon dioxide with high precision. Now, let me share how this unassuming material solves big challenges in different fields.

Saving the Day in Air & Gas Purification?

Do your production lines suffer from poor gas quality? My work improved when I introduced 13X molecular sieve, which helped deliver pure air and gas flows without hassle.

It achieves high-precision removal of moisture and carbon dioxide. It is like having an invisible assistant that ensures optimal gas quality for every job.

A Closer Look at Air & Gas Purification

I have a simple process in mind whenever I talk about 13X molecular sieve for air and gas purification. First, I think about how the sieve’s 10Å pores can trap tiny molecules. Then, I recall how polar molecules like water and carbon dioxide get drawn inside those pores. This targeted approach reduces the risk of contamination and helps me maintain consistent product purity.

I also learned that air dryers benefit from 13X molecular sieve because they must remove moisture at very high precision. Water vapor is the enemy in many systems. It leads to corrosion, clogs equipment, and hurts final product quality. So the sieve acts like a guard that halts water molecules before they cause damage. I once worked with a team designing an air separation plant. The biggest challenge was contamination in the oxygen and nitrogen streams. We placed 13X molecular sieve in the adsorber towers. The result was stable production and improved gas purity.

When I compare it to other adsorbents, I see that 13X has bigger pores than some of its cousins like 4A or 5A. That bigger pore size expands its range of adsorbed molecules. This helps me handle different contaminants. I call it my flexible partner that adapts to new tasks.

Below is a quick table that summarizes why I rely on 13X for air and gas purification:

| Factor | Why It Matters |

|---|---|

| Pore Size | Traps molecules up to 10Å wide |

| Selectivity for Water | High attraction to polar substances |

| Regenerability | Allows repeated use through desorption |

| System Efficiency | Lowers energy costs due to precise ads. |

The best part is its long lifespan. I have tested it under repeated adsorption-desorption cycles. It remains strong for many runs. This saves time and money. Plus, I can trust that it will keep working without losing performance too soon.

I sometimes joke that 13X molecular sieve deserves a Nobel Prize for Hardworking Materials. It tackles gas purification with minimal fuss. It also shows up in large-scale systems like power plants or smaller units like lab-scale analyzers. I never get tired of seeing it in action. It stands guard, eliminating water or CO2 and letting me focus on more creative aspects of process design.

The Refinery’s Secret Weapon: Crushing Moisture & Impurities?

Does your refinery struggle with water in feedstocks and harmful sulfur compounds? When I discovered 13X molecular sieve for my clients, it turned those problems around.

It removes moisture and sulfur-containing compounds from various streams. This stops corrosion and boosts efficiency in refining.

How 13X Molecular Sieve Fights Refinery Problems

My first refinery project introduced me to the power of 13X in removing moisture and impurities. I walked through the plant with the lead engineer, and we saw how water vapor caused pipeline blockages and catalyst deactivation in the reactors. I suggested adding 13X molecular sieve. The results surprised everyone. Water content dropped, product quality improved, and the entire system faced fewer downtime events.

I also noticed how 13X performs well against sulfur compounds like hydrogen sulfide. These compounds can poison catalysts and release harmful emissions if they are not removed. The large pore size of 13X allows it to capture bigger sulfur molecules. This is how it protects downstream processes.

Refineries often handle liquefied petroleum gas (LPG) and natural gas. These streams have to be dried and desulfurized. I rely on 13X because it keeps water and sulfur at bay, even when flow rates are high. My clients appreciate that it keeps pipelines clear and catalysts healthy. It also helps them meet environmental regulations. They do not have to worry about releasing harmful gases into the atmosphere. This fosters trust with local communities.

Below is a table that shows how 13X addresses common refinery woes:

| Refinery Concern | 13X Molecular Sieve Impact |

|---|---|

| Water in hydrocarbons | Dries the feed, reduces pipeline corrosion |

| Hydrogen sulfide (H2S) | Adsorbs sulfur compounds, prolongs catalyst life |

| Catalyst poisoning | Protects catalysts by reducing impurities |

| Product quality fluctuations | Ensures consistent purity in final products |

I like that 13X is not just a one-trick solution. It adapts to different processes. It can be regenerated by heating or lowering pressure, which makes it reusable. In a cost-driven industry, that is a game-changer. It means I do not need to purchase new adsorbent as often. Each time I reactivated the sieve, it returned to peak performance.

I once asked a friend who worked at another refinery why they did not use 13X. She said they tried older adsorbents that gave inconsistent results. I recommended they give 13X a new look. She switched, and her facility saw less equipment fouling. They also reported increased throughput. This reinforced my belief that sometimes the simplest approach is the best approach.

In the end, I see 13X as a silent hero that refineries often overlook. It hides behind the scenes, removing moisture and impurities, so everything else runs smoothly. It is the quiet friend who solves problems before they happen.

From Hospitals to Outer Space: The Ultimate Multitasker?

Have you ever imagined a material that supports medical oxygen generation and also scrubs air in space stations? I did not believe it until I used 13X molecular sieve.

It helps create high-purity oxygen for healthcare. It also filters carbon dioxide in aerospace systems, ensuring safe, breathable air for astronauts.

Why 13X Earns Its Multitasker Title

I remember when I visited a hospital’s oxygen generation unit. The staff needed a reliable adsorbent to separate nitrogen from oxygen. They also wanted to remove moisture. 13X molecular sieve helped them get high-purity oxygen for patients. This process works because of the sieve’s strong affinity for nitrogen and water. The medical team could focus on patient care, while 13X quietly ran in the background.

Later, I read about how spacecraft rely on molecular sieves to keep air breathable. Astronauts cannot open a window to let fresh air in. They need an efficient system to remove carbon dioxide and moisture. I was excited to learn that 13X was tested in many life-support systems for space missions. It helps maintain the right balance of gases. This means astronauts can live in a controlled environment with minimal risk of contamination.

Below is a simple breakdown of how 13X supports these two fields:

| Sector | Key Function of 13X Molecular Sieve |

|---|---|

| Medical (Hospitals) | Helps produce high-purity oxygen by adsorbing moisture, CO2, and nitrogen |

| Aerospace | Scrubs CO2 and moisture in closed environments, maintains safe air |

When I saw these applications, I realized 13X is more than a standard adsorbent. It becomes a life-saver. Hospitals rely on it for oxygen therapy. Astronauts trust it for extended missions. Factories use it for clean operations. Even everyday products like freezers might use a form of molecular sieve to keep frost in check.

I also admire 13X for its catalytic carrier properties. It can hold metal catalysts in its pores and facilitate chemical reactions. This is why it shows up in synthetic reactions or advanced material production. I once worked on a pilot project that used 13X as a catalyst support for hydrogenation. The reactions were faster and gave higher yields than earlier setups. This made me see how 13X is a toolbox of possibilities.

I always tell my colleagues that 13X is not flashy, but it never fails. It is consistent, dependable, and tough under pressure. One of my favorite success stories involved my friend Jacky, who designs chemical and air separation systems in Canada. He struggled with adsorbent poisoning in older systems. I suggested 13X. He reported fewer contamination issues and a longer operating cycle. Now he swears by it, too.

These examples remind me that big breakthroughs often come from small, hardworking materials. 13X might look like tiny beads, but it runs complex processes on Earth and beyond.

Conclusion

I see 13X molecular sieve as the tiny hero that keeps everything running smoothly, from refineries to hospital wards to space missions.