Moisture sneaks in and disrupts processes. That can lead to product damage or machine downtime. I have faced this problem many times, so I searched for a reliable fix.

My short answer is yes. 3A molecular sieves can trap water molecules while letting bigger molecules pass. This makes them perfect for controlling moisture in many situations. I have found them vital for industrial processes, storage, and other applications where dryness is critical.

I know how easy it is to lose track of humidity, especially when working with sensitive products. 3A molecular sieves seem small, but they work like guardians against moisture. Next, I want to share why these sieves are unique, how they apply across fields, and how to maximize their potential.

Why 3A Molecular Sieves Stand Out: The Science Behind Moisture Control?

People often ask me why 3A molecular sieves are so special. I say they deliver consistent dryness by filtering out water molecules and ignoring bigger molecules.

They stand out because of their 3-angstrom pore size. That size fits water molecules but not larger molecules. This selective adsorption ensures reliable moisture control. I have seen it boost product quality and cut downtime in factories. It is a simple yet powerful technology.

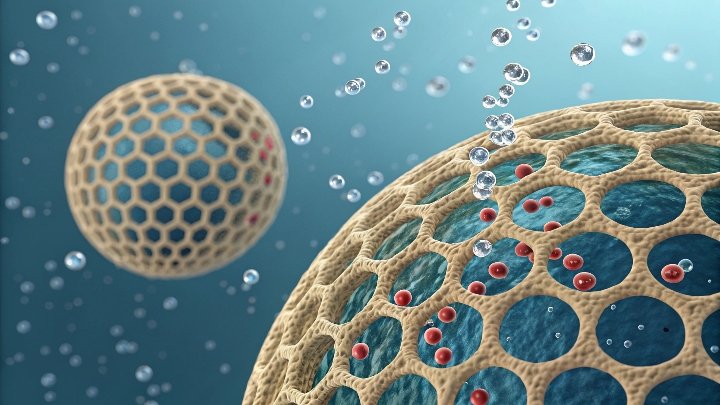

I like to think of the 3A molecular sieve as a tiny gatekeeper. It allows water molecules to enter its pores while rejecting molecules that are larger. This unique characteristic is due to the uniform pore openings that measure around 3 angstroms in diameter. That size is just right for capturing H2O. It also prevents bigger molecules from getting trapped. I see this as a form of precision sorting. It is the reason why 3A sieves are trusted for water removal in many settings.

Understanding the Mechanism

The mechanism behind 3A molecular sieves involves the strong attraction between the sieve surface and water molecules. These water molecules get locked inside the pores until the sieve is regenerated. The short distance inside each pore intensifies this attraction. This means the sieve can capture and hold a high volume of water. This prevents moisture from interfering with products or processes.

Comparing Different Molecular Sieve Types

Here is a simple table that shows some differences:

| Type | Pore Size | Main Use Case |

|---|---|---|

| 3A | ~3 angstroms | Water removal, general drying |

| 4A | ~4 angstroms | Water, ammonia, methanol |

| 5A | ~5 angstroms | Water, normal paraffins |

| 13X | ~10 angstroms | Bulk separation, CO2 removal |

I have tried other molecular sieve types as well. But I keep returning to 3A when water is the main issue. The unique 3-angstrom pore size is ideal for many water-sensitive processes. That includes drying natural gas, safeguarding medicines, and stabilizing adhesives or sealants. I have also seen it used in sealed double-glazed windows to keep the space free from moisture. This helps prevent fogging and condensation.

I often get asked if 3A sieves are fragile. In my experience, they are robust. They can handle high temperatures and pressures, as long as they are used correctly. That means following guidelines for regeneration and avoiding contaminating substances like oils or heavy organics. If used well, 3A sieves can last for many cycles. This makes them a cost-effective choice. They are a small package that solves big moisture problems."

Versatility in Action: Applications Across Industries?

I have worked with many industries that rely on 3A sieves. They are everywhere, from gas processing plants to food packaging lines, all because moisture can appear in unexpected ways.

I see 3A molecular sieves used to protect critical products from water damage. They dry natural gas, prevent pharmaceutical spoilage, and keep refrigerants stable. I have even seen them in labs, electronics storage, and packaging. They solve moisture problems wherever reliability and product integrity are essential.

I have observed how 3A molecular sieves step up to the challenge in different sectors. In natural gas processing, they help remove water vapor before the gas enters pipelines. This prevents pipeline corrosion. It also avoids hydrate formation that can clog the system. In pharmaceuticals, I see them used in packaging to keep moisture-sensitive medications stable. This helps preserve product potency and extends shelf life.

Food and Beverage Use

I have also seen 3A sieves in food and beverage applications. They help maintain freshness in products that can lose quality when exposed to moisture. For instance, powdered goods often clump or spoil if the humidity is too high. 3A sieves capture water molecules and preserve the texture and flavor. This is important for companies that need to keep their products crisp, tasty, or shelf-stable.

Electronics and Refrigeration

Electronics and refrigeration systems also depend on dryness. Moisture inside electrical components can cause short circuits or corrosion. In refrigeration, excess moisture can freeze and block internal passages. 3A sieves handle these issues by adsorbing water before it reaches sensitive parts. I have seen them installed in small-scale systems like home air conditioners, as well as large commercial cooling units. This helps maintain efficient cooling and reduces the need for repairs.

Why It Matters

I believe the wide reach of 3A sieves shows their adaptability. Different processes have different moisture thresholds, but a single solution often works for all. I remember a time when a friend struggled with repeated breakdowns in a cooling system. Installing a 3A molecular sieve filter helped solve the moisture problem almost overnight. The system ran smoother, and the maintenance costs dropped. That moment reminded me how a single, simple tool can keep many industries running smoothly.

I think the beauty of 3A sieves is their universal relevance. Whenever water poses a risk, these sieves find a place. They offer peace of mind to engineers, plant managers, and business owners who rely on stable, dry conditions. Their presence is often invisible, but their impact is clear."

Maximizing Performance: Tips for Using and Regenerating 3A Molecular Sieves?

I discovered early on that proper usage and regeneration can extend the life of 3A sieves. A few simple steps can keep them performing at their best.

You can maximize performance by keeping them away from contaminants. Regenerate them by heating or purging with dry gas until moisture is driven off. Always monitor their condition. If you see pressure drops or changes in dryness, it might be time for a fresh regeneration or replacement.

I have learned that the success of 3A molecular sieves depends on correct handling and maintenance. First, it is important to store them in airtight containers before use. They can start to adsorb moisture from the air if left exposed. This lowers their capacity for the actual application. It is best to keep them sealed until they are needed.

Proper Setup

When installing 3A sieves in a system, I suggest checking the operating temperature and pressure. Extreme conditions can affect performance. Too high a temperature might reduce the sieve's capacity to hold water. On the other hand, if the temperature is too low, water may freeze and cause blockages. I always follow supplier recommendations and adjust the process to fit the sieve's optimal range.

Regeneration Methods

Regeneration is the key to reusing 3A sieves many times. There are different ways to regenerate them. Heating them above 200°C is common. This drives out trapped water. Another method is purging with a dry gas stream. I have used hot air or nitrogen purges for efficient regeneration. It is crucial to do this step thoroughly. Any leftover moisture can reduce the next adsorption cycle. I also keep an eye on the regeneration time. Rushing this step can compromise the outcome.

Monitoring Performance

It is also wise to monitor differential pressure across the sieve bed. A sudden increase might signal clogging or contamination. Regular checks of outlet moisture levels help me track performance. If dryness levels start to rise, it might mean the sieve is close to saturation or has been fouled by contaminants. In such cases, regeneration or replacement is necessary. I also avoid contact with substances like oils or heavy organics. Those can block the pores and reduce effectiveness. By following these steps, I have kept 3A molecular sieves running at full capacity for longer periods. This saves money and reduces waste. It also ensures stable, moisture-free operations that help me meet production goals."

Conclusion

3A molecular sieves are a reliable answer to moisture problems. I have seen them excel in various industries, and proper care makes them last. They are my top recommendation.