I once struggled to see which molecules molecular sieves attract. I needed a simple answer, and my curiosity led me to investigate, then share these findings with others.

Molecular sieves attract small or polar molecules and keep out bulky ones. They use specific pore sizes, polarity, and shape selectivity to ensure precise separation and purification.

I see that pore size, polarity, and shape all matter when it comes to adsorption. I will explain each point in detail so we can get a clearer picture.

What do molecular sieves absorb?

I often asked myself which specific substances tend to get locked inside these sieves. I wanted a quick list that I could refer to at any time.

They typically absorb water, polar molecules, and smaller gases. The exact outcome depends on pore size, polarity, and how the molecule fits into the lattice.

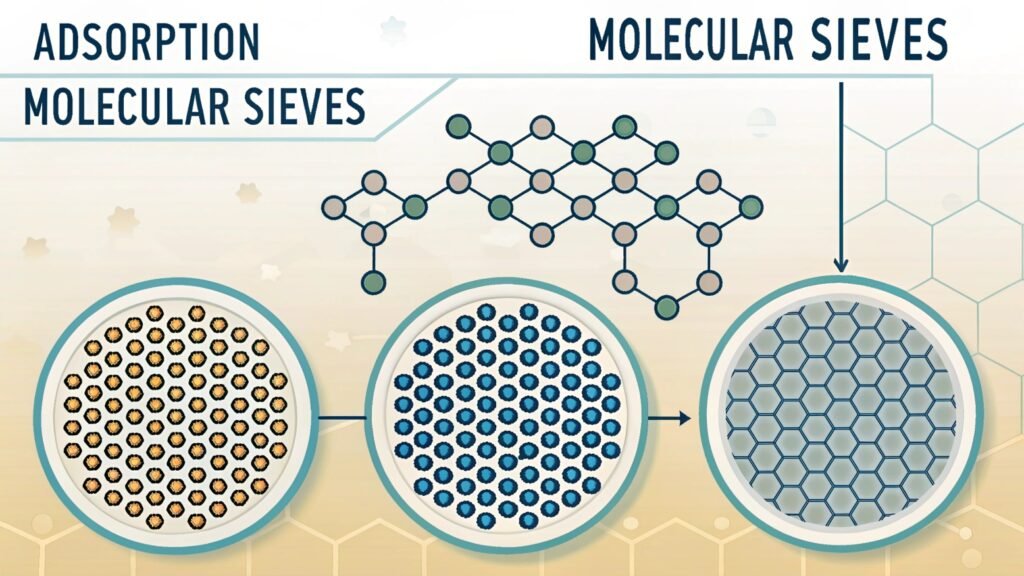

I find that pore size is the first key factor. If I use a 3A molecular sieve, it will accept molecules with diameters up to about 3 angstroms. That means it can trap water, which is small and polar, while rejecting bigger species. If I switch to a 4A sieve, I can capture molecules like ammonia, methanol, or even some small hydrocarbons. This tight size-based screening is how we can separate water from other compounds. It is efficient, and I see it used all the time in drying processes.

I also know that polarity plays a big role. Polar substances have partial charges that interact with the internal sites of the sieve. Water molecules, with their strong dipole, stick very firmly to a 3A or 4A sieve. Alcohols also interact well if they are small enough. On the other hand, non-polar molecules, like some alkane gases, are less attracted. They may still get trapped if the pores match their size, but the interaction is weaker compared to polar molecules. I recall a time when I tried to remove trace water from an alcohol-based feed in my own work. I picked a 3A sieve. It let the alcohol pass through while it locked away the water. It was a straightforward fix.

Molecular shape also matters. Linear molecules go in more easily. Branched or bulky molecules can be blocked if the pore entrance is too narrow or if the channels have twists that prevent easy passage. I once did an experiment where a linear chain hydrocarbon was separated from a branched one, simply by passing them through a bed of molecular sieves. The branched version stayed out, while the linear form was trapped. This shape selectivity is why I often refer to molecular sieves as a precise filtering system. It is not just about size; it is also about how well the molecule aligns with the internal cavities.

Sometimes I mix these ideas to tackle more complex tasks. If I have a mixture of water, alcohols, and other components, I choose a sieve with the right pore size to selectively remove water while letting the other compounds pass. I even consider the partial charges involved. These guidelines help me build an adsorption approach that is both efficient and cost-effective. After seeing how well this method works, I started using molecular sieves not only for drying but also for removing impurities in my experiments. They became a go-to tool. The design is simple, the principle is intuitive, and the results are reliable. That is why I feel comfortable recommending molecular sieves as an ideal solution for many scenarios.

What are molecular sieve adsorbents?

I once looked for a simple definition of molecular sieve adsorbents, because I got lost in technical details. Then I found a clear explanation that guided me.

Molecular sieve adsorbents are structured materials with uniform pores. They separate molecules by letting certain ones in while blocking others, guided by size, polarity, and shape.

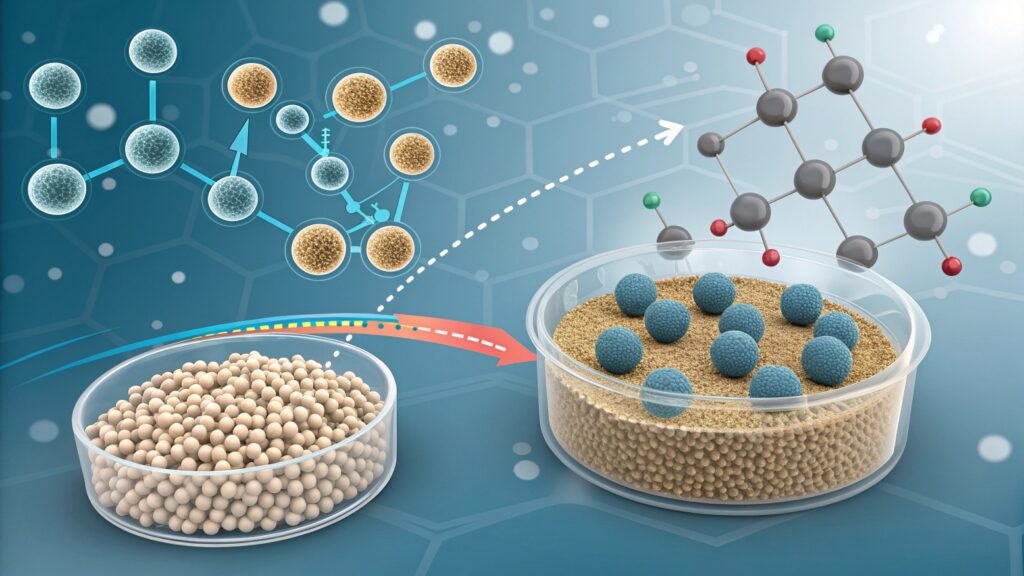

Molecular sieve adsorbents are usually made of zeolites, which are crystalline aluminosilicates. Their frameworks contain aluminum, silicon, and oxygen atoms in a specific pattern that results in a network of channels and cavities. These channels have nearly identical pore sizes, which is the core of their power. When I feed a mixture through a molecular sieve, only molecules that fit can get inside. The rest remain in the flow that bypasses the adsorbent. This mechanical filtering is similar to a sieve in the kitchen, but on a molecular scale. I remember reading about how zeolites occur in nature, but the ones we use for industrial purposes are often synthesized to have consistent properties.

When I look closely at the structure, I notice cations like sodium, potassium, or calcium. They occupy positions in the lattice and can slightly alter the pore dimensions. If I swap sodium ions for potassium ions in a 4A zeolite, I get a 3A molecular sieve. The difference in the ionic radius changes the effective pore opening. This is how we calibrate which molecules get trapped. In my early projects, I had to remove traces of moisture from a solvent. A 3A sieve was the most efficient choice. It removed the water, but did not capture the solvent. That saved me time and money by preventing contamination and wasted product.

Another factor is the role of polarity. Zeolite surfaces carry negative charges, balanced by positive cations. Polar molecules, like water, experience strong attractions to these sites. Non-polar molecules, like many hydrocarbons, are less drawn unless they are small enough to fit and there is no competition from more polar substances. This property is why molecular sieve adsorbents work so well in drying. Water is more strongly drawn in than other components. I even used 4A sieves to remove carbon dioxide from a gas stream once, because CO2 can interact with the polar sites. It was an interesting project that showed me how flexible these materials are.

I also see that shape selectivity is a powerful feature. Molecules that are bulky may be too wide for the entrance. If they cannot pass through the pore opening, they remain in the external phase. That is often used in refining. For example, linear paraffins can fit into a sieve, while branched ones cannot. By leveraging that, refineries can separate these components to achieve a higher-quality product. The beauty of molecular sieve adsorbents is their reproducibility. Each particle of a given type has the same pore size and the same chemistry. This consistency allows large-scale processes to run without surprises. I recall seeing massive industrial towers packed with molecular sieve pellets. They handle high flows, remove or separate the target molecules, and then get regenerated for the next cycle. That cyclical process is central to many separation systems, including Pressure Swing Adsorption and Temperature Swing Adsorption. After seeing these operations up close, I realized how vital molecular sieves are for modern chemical engineering. They are not just another material. They stand at the heart of many crucial processes, helping to create purer products at a lower cost and with greater efficiency.

What are molecular sieves useful for?

I have come across them in large factories and tiny labs. I wanted to see the main uses in a straightforward list to guide my decisions.

They remove water from liquids and gases, separate certain components, and improve purity. They rely on pore size, polarity interactions, and shape constraints to deliver targeted results.

Molecular sieves excel at drying. I often use them to remove water from solvents in small lab setups. That is because water is a polar molecule of small size, and it fits well into the pores. Once inside, water remains there until we regenerate the sieve. This principle translates to large-scale operations too. For instance, in a compressed air system, the presence of water can lead to corrosion and icing. Passing that air through a molecular sieve bed captures the moisture, leaving drier air that performs better in downstream equipment. I remember a time when a colleague forgot to replace the spent sieve in a pilot plant. We started seeing moisture creep back into the product stream. That reminded me how critical it is to maintain fresh or regenerated adsorbent to keep our processes running optimally.

These sieves also help in gas separation. I have seen them used in air separation units. Nitrogen interacts differently with the pore surfaces than oxygen does, so I can configure a system to adsorb nitrogen and allow oxygen to pass, or vice versa. The difference is subtle, but when I cycle through pressure or temperature swings, I can separate the gases at an industrial scale. Another example is hydrogen purification, where trace carbon monoxide or carbon dioxide can be captured, leaving a purer hydrogen stream. I admire how these systems rely on known interactions between gas molecules and the adsorbent. Each step is consistent and predictable if I choose the right sieve.

Refining processes also use molecular sieves. In petroleum refining, we can separate linear hydrocarbons from branched ones. The shape of the molecule matters a lot here. Linear hydrocarbons slide into the pore channels, while branched ones cannot. That helps produce better fuels by allowing refiners to modify the product mix. I once visited a refinery where I saw entire columns dedicated to this shape-based separation. It was fascinating to see that advanced technology pivot on something as simple as whether a molecule is straight or curved.

Molecular sieves are also useful for removing contaminants. They can trap volatile organic compounds, bad odors, or harmful chemicals in wastewater treatment projects. I personally worked on an environmental project where we needed to take out certain industrial solvents from water streams. The small, polar solvents were quickly adsorbed, while the larger, less polar components remained in the water. Then we regenerated the sieves to handle another batch. It was a repeating cycle that saved time and reduced the cost of disposal or complicated treatments. It also gave the environment a break from harmful effluents.

Another key use I often see is in chemical purification. If I have a reaction mixture that must be free from water or other small contaminants, I add molecular sieves to bind those unwanted substances. That ensures the reaction remains efficient. In pharmaceutical processes, dryness is often critical. Synthesis steps can fail if water is present. Using molecular sieves is an easy way to keep moisture levels under control, especially compared to more complicated distillation setups. The result is a cleaner reaction path. By controlling these details, I can push a process closer to the desired outcome, saving energy and raw materials in the process.

Finally, I remember the first time I applied molecular sieves in a personal project. I was working on a homemade dehydration experiment, trying to create a very dry environment for a sensitive test. I placed the sieves in a sealed chamber, and they pulled out residual moisture. The difference was immediate and measurable. That success made me more confident in using these materials in bigger tasks. Now, I recommend them whenever someone asks how to achieve dryness or how to separate a specific molecule from a blend. Over time, I have realized that molecular sieves are an indispensable tool in the chemical world. Their wide range of uses underscores how critical they are to modern industry, from gas plants to research labs, and from refineries to even personal DIY projects.

Conclusion

Molecular sieves let me target specific molecules through well-defined pore sizes and polarity, making them key players for drying, separating, and purifying in many applications.