I once wrestled with unreliable oxygen generation. I felt annoyed when output fell short. Then I found 13X-HP molecular sieve. Let me show how it frees us from limits.

If you want to see how 13X-HP can boost oxygen purity to amazing levels, keep reading. This special X-type sieve can target nitrogen and carbon dioxide. It helps us collect higher-purity oxygen. That means smooth performance for industrial, medical, and home oxygen setups.

I want to explain how 13X-HP can be a strong tool for air separation. Please continue reading and see how it changes oxygen production forever.

What Makes 13X-HP Molecular Sieve So Special?

I remember my first attempt at maximizing oxygen yield. The system felt weak. With 13X-HP, I finally saw faster adsorption and stable purity. This clarity changed everything for me.

13X-HP stands out because it focuses on enhanced adsorption power. It grabs nitrogen with high efficiency. This leaves more oxygen for us. It also prevents moisture problems. That means we get better performance and longer product life.

I want to unpack the features that set 13X-HP apart from ordinary X-type molecular sieves. This specialized variant focuses on capturing nitrogen and carbon dioxide. That is essential for oxygen generation. I learned that the wide pore structure allows the sieve to differentiate between molecules based on size and polarity. This helps remove unwanted gases more effectively. The result is higher oxygen purity, which benefits industries like healthcare, steel manufacturing, and home healthcare systems.

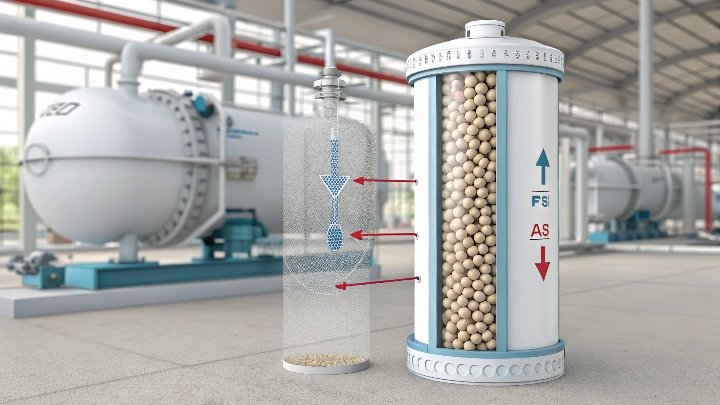

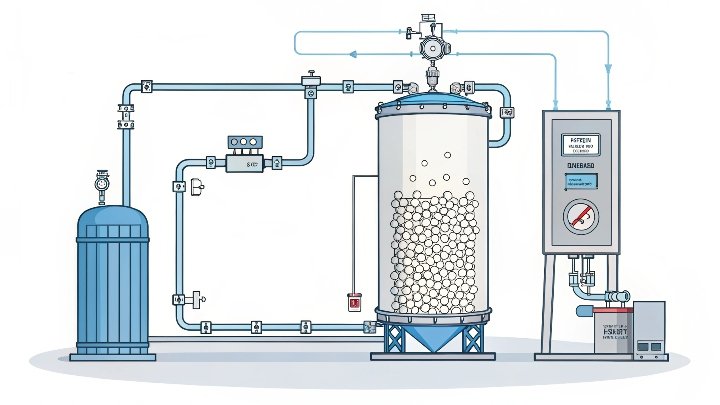

Unique X-Type Structure

The X-type framework uses a robust lattice. That lattice is stable under pressure swing adsorption cycles. Each cycle draws in air through a compressor. The sieve holds nitrogen and carbon dioxide. Then it leaves oxygen behind. When the pressure changes, the trapped molecules are released. This cyclical process is fast and efficient with 13X-HP because of its optimized pore distribution.

Superior Adsorption Efficiency

I experienced the difference when I switched from a standard sieve to 13X-HP. Nitrogen uptake was quicker, which meant less time spent purifying oxygen. There was also improved separation between oxygen and nitrogen. This translates into consistent oxygen purity levels that can reach or exceed medical standards. That gives manufacturers confidence in their product’s performance and reliability.

Below is a simple table that compares common properties:

| Property | 13X-HP Sieve | Standard 13X Sieve |

|---|---|---|

| Adsorption Speed | High | Moderate |

| Nitrogen Uptake | Excellent | Good |

| Oxygen Purity | Up to Medical | Variable |

| Cycling Durability | Long | Average |

| Moisture Resistance | Strong | Standard |

These properties show why 13X-HP is a strong choice. It helps me avoid frequent replacement. It boosts efficiency. It also helps me maintain stable operation. I no longer worry about subpar oxygen purity or unexpected downtime. That is why I see this sieve as special and worth the investment.

Top Applications of 13X-HP Molecular Sieve

I once tried to expand into medical oxygen systems. I faced strict purity requirements. 13X-HP soared past those demands. It helps me tackle projects from home devices to huge industrial plants.

13X-HP plays key roles in medical, industrial, and residential oxygen generation. It can handle strict standards for hospitals and smaller demands for home care. Its versatility is remarkable.

I have seen 13X-HP used in many scenarios. I got involved in medical oxygen plants. Hospitals need constant oxygen flow with no contamination risks. That is where 13X-HP excels. Its high nitrogen capture means we achieve the required purity for critical care. The stable adsorption properties help keep oxygen flowing smoothly. During a major project, I watched doctors rely on a system that used 13X-HP. They were pleased with the consistent results.

Industrial Operations

In large-scale factories, oxygen can be needed for metal cutting, glass manufacturing, or chemical processing. Traditional sieves might slow production due to frequent changes or lower adsorption capacity. 13X-HP changes that experience. It handles heavy loads while still providing clean oxygen output. I once worked on an iron production facility project. They needed steady oxygen to optimize their furnaces. 13X-HP delivered stable flow, which improved efficiency and lowered operating costs.

Home Oxygen Systems

At home, many people need oxygen therapy. These small devices must be efficient and quiet. They rely on 13X-HP to keep power consumption low and purity high. I talked to a family friend who noticed a big difference in reliability after switching to a device with 13X-HP. They found it easier to handle daily tasks without worrying about oxygen supply.

Here is a basic comparison table that shows key requirements:

| Application | Oxygen Purity Needs | Typical Flow Rate | 13X-HP Advantage |

|---|---|---|---|

| Medical | Very High | Medium to High | Stable Purity, Low Risk |

| Industrial | High | Very High | Consistent Flow |

| Home Therapy | Moderate to High | Low to Medium | Quiet, Energy Efficient |

These examples show the universal appeal of 13X-HP. It manages different throughput levels and purity standards with ease. I find it suitable for nearly any oxygen-related project.

Why 13X-HP is a Total Game-Changer

I used many adsorbents before. But 13X-HP gave me fewer service calls, smoother performance, and longer lifespan. I believe this sieve is a true game-changer for air separation systems.

13X-HP stands out for its faster adsorption, higher nitrogen selectivity, and longer service life. These features make oxygen production more reliable. In other words, it saves time, cuts costs, and raises product quality.

I often get asked why 13X-HP is different from standard solutions. I see three big reasons: advanced adsorption efficiency, better longevity, and robust performance under high pressure. When I started using CNM 13-HP, I noticed it reached oxygen purity targets faster than any typical sieve. That speed helped me scale up operations without sacrificing quality. The higher nitrogen selectivity also meant I spent less time dealing with byproducts. Instead, I could concentrate on improving the core process.

Another benefit is the long service life. Frequent adsorbent replacements can raise costs and cause downtime. 13X-HP uses a durable structure that withstands repeated pressure swings. This structure helps it maintain its performance for a longer period. I remember one project where we replaced a different sieve with 13X-HP. The maintenance intervals became longer. That led to reduced operating costs and fewer system interruptions. Customers appreciated the consistent oxygen supply.

The final advantage is how 13X-HP manages moisture and contaminants. Some sieves degrade when exposed to water or certain impurities. But 13X-HP has a high tolerance. That tolerance keeps it working at peak levels. By effectively removing nitrogen and other waste gases, 13X-HP offers a stable, efficient oxygen stream. I find that it transforms the way we approach air separation. Instead of wrestling with inefficiencies or guesswork, we get clear, reliable results.

Because of these reasons, I call 13X-HP a total game-changer. It addresses core pain points: speed, purity, cost, and durability. That combination sets a new benchmark for adsorbent technology in oxygen generation.

Conclusion

I believe 13X-HP transforms oxygen generation. Its speed, purity, and durability set it apart. I hope my findings help you make a confident choice.