4A Molecular Sieve

4A molecular sieve is one of the most consumable molecular sieves used in the industry, its selective adsorption to water is higher than any other molecule. Chemequip 4A molecular sieve adsorbs water, methanol, ethanol, hydrogen sulfide, sulfur dioxide, carbon dioxide, ethylene, propylene and other molecules with diameters not more than 4 angstroms. Usually used for gas and liquid drying but also for refining and purification of certain gases or liquids, such as the preparation of argon

HOT SELLING Molecular Sieve

Molecular Sieve 4A Application

- Detergent auxiliary, soap molding agent, toothpaste abrasive

- Sewage treatment, heavy metal recovery

- Water softener, soil conditioner

- Separating agent in metallurgical industry

- Catalyst, desiccant, adsorbent in petrochemical industry

- Silver zeolite antibacterial agent in pharmaceutical industry

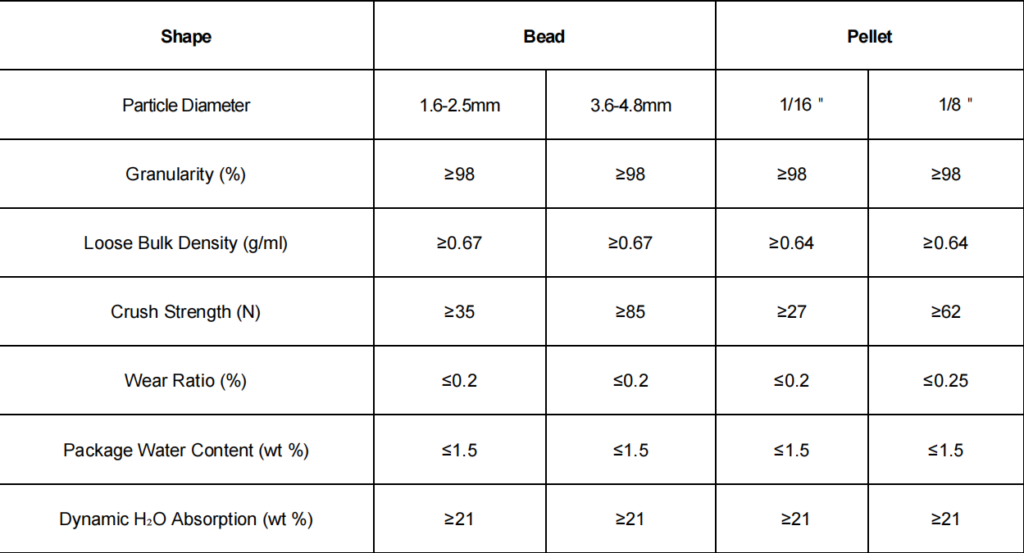

Molecular Sieve 4A Technical Specification

Molecular Sieve 4A Packing

- PE Carton 25/50kg

- Ton/half ton bag package

- Iron drum, net weight 125/135/140kgs

- Customized package by customer requirements

Molecular Sieve 4A Storage

- Room temperature; indoor humidity not more than 90%

- Avoid water, acid and alkali; isolate air and sealed preservation.

Molecular Sieve 4A Regeneration

Chemequip 4A molecular sieve can be purged and regenerated by increasing the temperature, regeneration (dehydration) degree depends on the humidity and temperature of the purging gas.

Water Removal: Heat dry gas such as nitrogen, air, hydrogen, saturated hydrogen carbide to 150-320℃, then pass it into the molecular sieve bed under the pressure of 0.3-0.5 kg/m2 for 3-4 hours, and then pass the dry cold gas into the adsorber for 2-3 hours, isolate the air and cool it to room temperature.

Organic Removal: Replace the adsorbent from the molecular sieve by water vapor, and then heat. Or pass into hot vapor or inert gas at the in 200-350℃, not use gases that produce explosive mixtures by contact with the adsorbent.

Gas Removal: Reduce the pressure

Wanna dig deeper in cooperation?

Molecular Sieve 4A Application Case

Molecular Sieve 4A Technical Specification

- Project: Natural Gas Drying for Pipeline Transport

- Client: A major energy supplier in North America

- Challenge: The client needed to remove water and CO₂ from natural gas to prevent hydrate formation and corrosion in pipelines. Traditional desiccants struggled with high moisture swings and required frequent replacement.

- Solution: We supplied high-capacity 4A molecular sieves from CNM Stable, featuring a 4Å pore structure optimized for deep dehydration and CO₂ co-adsorption. The sieves were packed into a twin-tower adsorption system for continuous operation.

- Results:

- ✔ Dew point below -100°F (-73°C) achieved, exceeding pipeline standards

- ✔ 20% higher adsorption capacity vs. silica gel, reducing vessel size

- ✔ Longer service life with minimal degradation after 5+ years

- Why 4A?

- Superior water selectivity, even in high-CO₂ streams

- Minimal attrition loss in high-flow conditions

- Regenerable at 250–300°C for cost-effective reuse