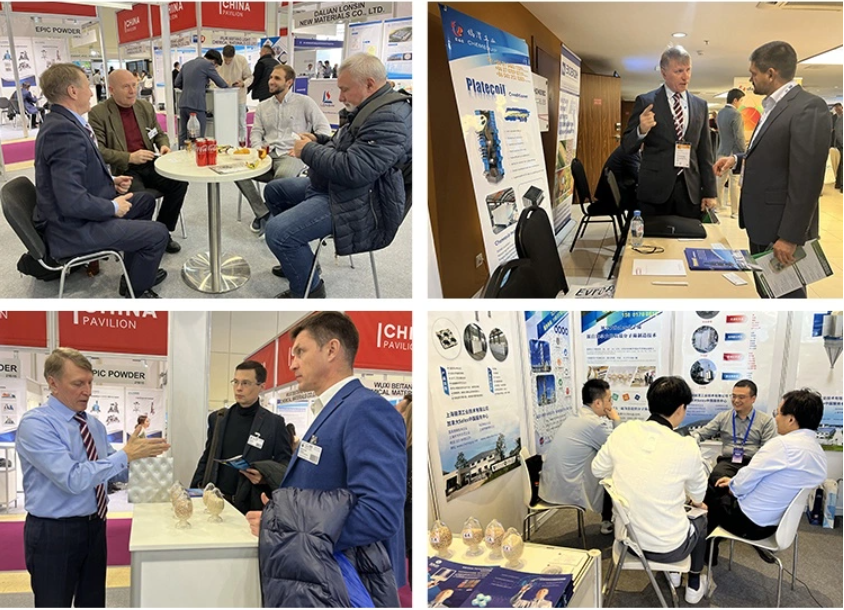

About CNM

You can expect quality molecular sieve and professional service from CNM.

Our team have manufacturing experience more than 20 years. Export business more than 20 years.

CNM MOLECULAR SIEVE PLANT

Product advantages

The biggest advantage of our products is that they are with nice quality and apperance, at same time cost-effective. We are in the wholesale business.

We are looking for wholesaler and distributor from all of world to start cooperation. You will get all our advantages, not only competitive price but also best solution.

Platform advantages

We have been launching the B2B platform before, but the effect has declined seriously in recent years, so we need to do a website to do marketing and sell goods.

We hate pure price wars, and we hope that everyone will work with us to provide the world with more cost-effective but not cheap sieve products.

Sourcing from CNM before the price of raw materials increases!

Why Choose CNM

20+ years

Experience in the chemical industry. Originated in Shanghai Customers Worldwide

200+ Employees

R&D department, marketing department, production workshop and QC team

100+ Patents

Own more than forty independent intellectual property rights

20,000+ Output

Annual output is 20000 tons, including molecular sieve beads and pellets

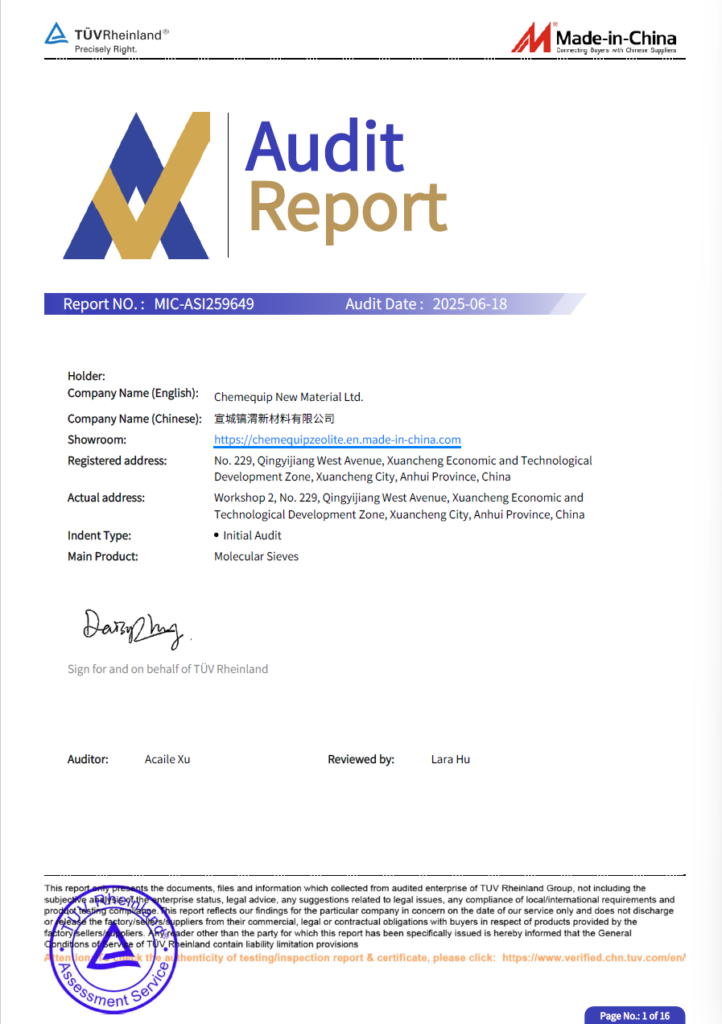

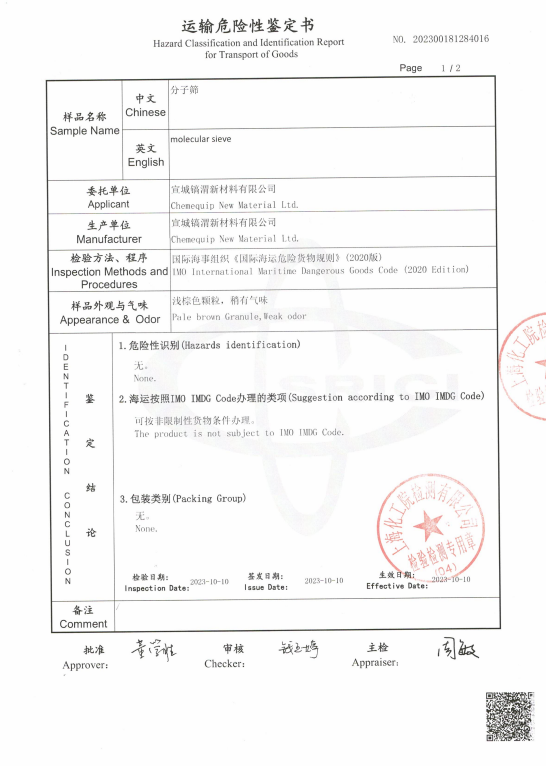

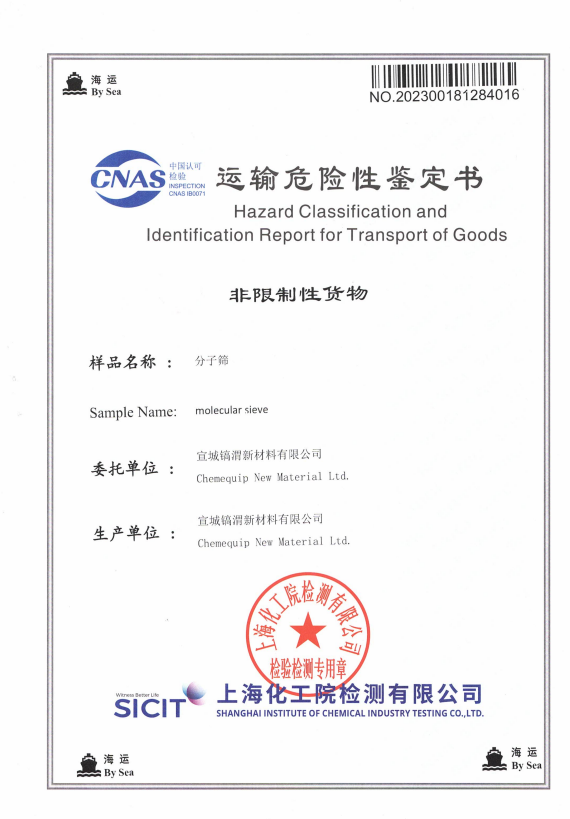

HONOR CERTIFICATE

Dedicated to delivering premium molecular sieves with consistent excellence!

Molecular sieves desiccants are widely effective in removing the water or moisture from different liquids and gases. The crystalline composition, make it a perfect solution to absorb the water and other impurities to obtain the pure liquid or gas as compared to other separation systems. The excellent efficiency and easy-to-use adsorption system play a great role in resolving the moisture control problems in pharmaceutical, petrochemical, food, natural gas, transportation, and other industries. Our all products are available in bulk quantity or in pre-packaged quantities.

CNM CHINA is considered as the leading desiccant supplier, that provides highly effective solutions to the industries looking for maintaining the lowest possible relative moisture. Molecular sieve has the ability to adsorb the water molecules in the range of temperature as compared to other desiccant materials.

Being one of the top molecular sieve manufacturers and suppliers in CHINA, our team is strongly committed to providing the highest quality products and related services to the customers. Our team of highly qualified and trained engineers allows us to accomplish the diverse requirements of an individual client as well as large industrial needs.

The types of molecular sieves desiccants offered by CNM CHINA include 3A, 4A, 5A and 13X molecular sieves which are available in the form of beads, pellets, and powder. Also, CNM CHINA is the best carbon molecular sieves manufacturers in CHINA. The molecular sieves with different pore sizes have their own importance in the range of applications depending on their molecular diameters and polarity. These include natural gas drying, insulated glass dehydration, solvent drying and distillation, oxygen purification, mercaptan removal, sweetening process, etc. We focus on developing innovative products that work efficiently to meet even the complex challenges of the specific adsorption requirements. We work extremely hard to solve all humidity related problems and offer a great way to protect your products.

WE DO HAVE A REPUTATION