I saw damaged beer quality from hidden moisture. I also witnessed corroded gas pipelines from water. I needed a solution.

Molecular sieves act like tiny filters. They remove water from beer and gas. These sieves catch moisture before it ruins taste and corrodes pipelines.

I discovered that these materials solve more than one moisture problem. They protect beer in breweries. They also remove water in gas fields. Let me explain how.

Brewery to Gas Field: The Nano-Switch Controlling Water in 300+ Industries?

I saw many factories use outdated drying methods. This caused product waste. I wanted a better drying tool.

Molecular sieves solve the water challenge for beer, fuel, and chemicals. They capture water so other ingredients stay pure.

Why pore size matters in countless processes

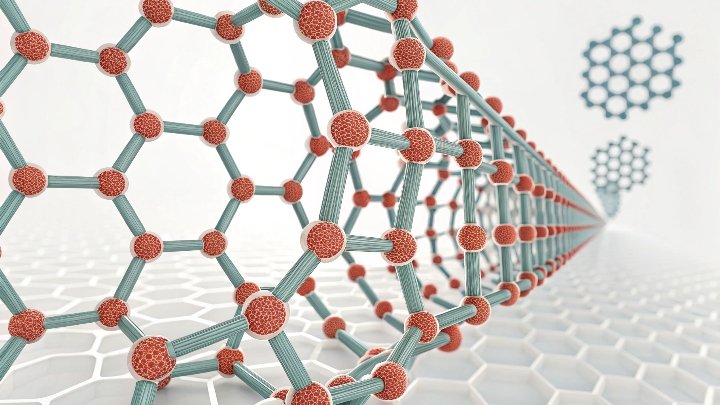

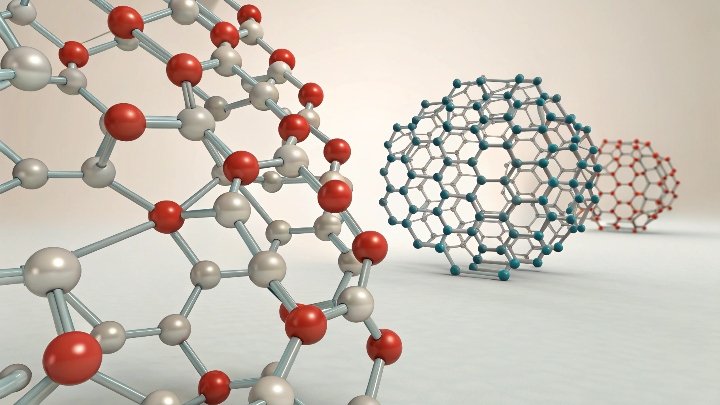

I learned that pore size is the key feature of molecular sieves. Each sieve has fixed pore openings measured in angstroms. That is very small—on the scale of molecules. If a molecule is smaller than the pore, it goes in and gets trapped. If it is larger, it stays out.

I watched breweries use 3A molecular sieves. These are perfect for trapping water molecules while leaving bigger flavor compounds. This keeps beer stable. Natural gas processing facilities often use 4A molecular sieves. These remove moisture and acidic gases. That stops corrosion and hydrates in pipelines. The result is a cleaner, safer fuel that meets pipeline standards.

I noticed that pore size also matters for other areas. In petrochemicals, 5A sieves can capture normal paraffins. This helps refine pure gasoline components. Meanwhile, 13X sieves can remove CO₂ from gas streams. This is especially important for advanced air separation processes or for capturing carbon in chemical plants.

I saw that the global market for these sieves was around $5.1 billion in 2020, and it is set to exceed $6.8 billion by 2026. Many industries use them. Some target dryness in pharmaceuticals. Others address moisture control in food packaging. The versatility is amazing. Small differences in pore size yield big impacts. This is the essence of the “nano-switch.” By choosing the right pore size, I can target a specific molecule. This is how more than 300 industries control water and other unwanted components.

Extending Shelf Life: How Brewers Gain 60% Profit Margin with Smart Adsorbents?

I watched brewers lose profits because of spoilage. That was a real pain. I wanted to stop that waste.

Smart adsorbents like molecular sieves control moisture. When beer stays stable longer, margins increase.

How molecular sieves improve freshness and reduce costs?

I remember visiting a brewery that struggled with early spoilage in its beer. Their major issue was residual water that allowed microbial growth. The brewery tested many fixes. They used conventional drying equipment, but it was inefficient. Then they tried molecular sieves. They placed 3A sieves in their process line to remove trace water. This protected the flavor profile and boosted shelf life. Consumers noticed the quality, and the brewery saw profit margins soar.

I learned that molecular sieves use physisorption rather than chemical bonding. That means they rely on mild attractions to trap water molecules in the pores. This mechanism keeps the beer’s delicate chemistry intact. The process is especially important in premium craft brewing, where the aroma and taste must remain stable. Brewers often reuse the sieves. Regeneration can be done by heating or by applying low pressure. This cuts down on operational costs.

Temperature and pressure also affect how well the sieves work. Higher pressure can drive more water into the pores. Lower temperature helps hold molecules in place. Brewers tweak these conditions for maximum efficiency. The brewer I visited found an ideal cycle time that balanced throughput with dryness.

I also noted that some breweries use a mix of adsorbents. Silica gel is sometimes used to polish clarity, and activated alumina can help with certain impurities. But molecular sieves get that final dryness. Because they reduce water to very low levels, they extend shelf life. The brewers can ship their product longer distances. This leads to a 60% margin boost. They reach more markets without quality loss.

The Invisible Bouncer: How Molecular Sieves Filter 0.3nm Water Molecules?

I saw hidden water molecules spoil many products. I needed a bouncer that could block those tiny water molecules.

Molecular sieves act like doormen. They catch 0.3nm water molecules and let bigger molecules pass.

From physisorption to carbon molecular sieves

I realized that water molecules measure roughly 0.3nm across. That is much smaller than most organic molecules. Molecular sieves that have a pore size around 3 angstroms (3A) can filter out water and leave larger molecules untouched. This principle is useful in multiple industries.

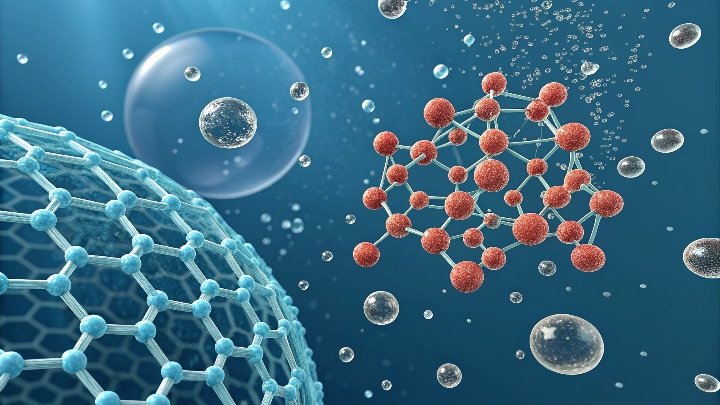

Physisorption is the main mechanism. Water molecules slip into the pores. They are held by weak Van der Waals forces. It is different from chemisorption, which forms chemical bonds. With physisorption, we can release these trapped molecules later through heat or pressure changes. This cycle is key for reusing the adsorbent.

I also discovered that not all molecular sieves are the same. Zeolite-based sieves have a crystalline structure that is inorganic. But carbon molecular sieves (CMS) are made from carbon sources like coal or coconut shells. CMS have a wide distribution of pore sizes. They can remove nitrogen or separate oxygen from air. This is done with pressure swing adsorption (PSA). I once visited an air separation plant. They used CMS to get high-purity nitrogen. They also used them to capture unwanted VOCs (volatile organic compounds) from exhaust streams.

I compared molecular sieves with other drying materials. Silica gel is cheap and easy to regenerate at low temperatures, but it does not achieve very low moisture levels. Activated alumina has a moderate capacity for water but lacks the precise pore control that molecular sieves provide. Molecular sieves offer the highest adsorption capacity for deep drying. I saw them achieve ultra-low dew points. That is a big deal for processes like freeze-drying and certain pharmaceutical steps. The “invisible bouncer” principle is clear. If water tries to enter your system, these sieves stand guard. They let other molecules pass, but keep water locked away.

Conclusion

Molecular sieves remove tiny water molecules from many products and make processes more efficient.