For two decades, one technology dominated the molecular sieve market. But what was it about Sorbex™ that made it the undisputed leader in this field?

Sorbex™ technology redefined molecular sieve standards over its 20-year reign, offering unparalleled performance in refining and petrochemical applications. It reshaped the industry by delivering more reliable, energy-efficient, and cost-effective solutions.

While the technology led the market for years, changes in industry dynamics and new advancements began to challenge its long-standing monopoly. Let’s explore how Sorbex™ set new standards and how the market evolved in its wake.

Sorbex™ Technology: The Beginning of a 20-Year Dominance?

How did Sorbex™ manage to maintain its dominance for two decades? What set it apart from its competitors and allowed it to maintain an edge in a competitive market?

Sorbex™ revolutionized molecular sieve technology with its superior adsorption efficiency, durability, and energy performance. Its introduction marked a new era of performance standards that competitors struggled to match.

When Sorbex™ was first introduced by UOP/Honeywell in the early 1990s, it didn’t just provide an incremental improvement over existing molecular sieve products. It set a completely new bar for molecular sieve technology. The main feature that set Sorbex™ apart was its high capacity for adsorption and long cycle life, which directly translated into higher energy efficiency and cost savings for users. This was especially critical in industries like refining and petrochemicals, where the need for constant separation and purification of gases and liquids demands both reliability and consistency.

The technology’s ability to optimize regeneration cycles meant that users could rely on fewer maintenance shutdowns, thus reducing overall operating costs. Another key factor that contributed to Sorbex™’s dominance was its superior stability under various harsh operating conditions. The robust performance of Sorbex™ in high temperatures and varying pressures made it a trusted solution in critical applications, such as the removal of water and CO2 from natural gas and biogas.

Furthermore, Sorbex™ made a lasting impact on process optimization. It allowed companies to fine-tune their operations for better efficiency, which contributed directly to the profitability of projects in petrochemical industries. For nearly two decades, Sorbex™ was the go-to choice, setting a standard of excellence that other molecular sieve products struggled to meet.

How UOP/Honeywell’s Sorbex™ Set New Standards for Molecular Sieves?

What exactly made Sorbex™ such a game-changer? How did UOP/Honeywell elevate the molecular sieve industry?

Sorbex™ elevated the molecular sieve market with its cutting-edge adsorption technology. By introducing enhanced energy efficiency and process optimization, it became the industry benchmark for molecular sieve applications.

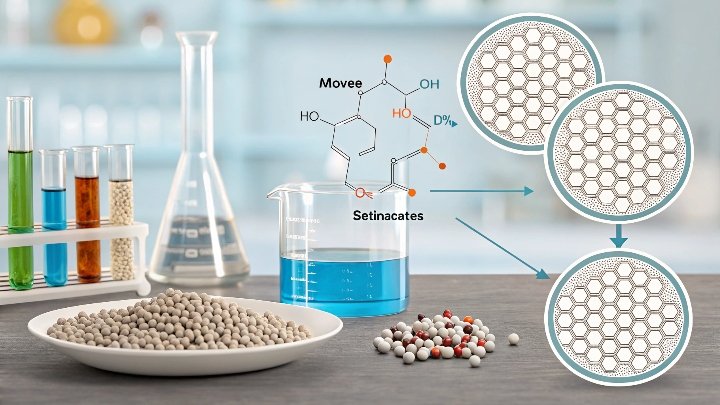

Sorbex™ wasn’t just another product in a crowded market. It was the result of continuous research and development by UOP/Honeywell. The development focused on optimizing the core functionality of molecular sieves—adsorption efficiency. In traditional molecular sieves, the focus was primarily on adsorption capacity and speed. Sorbex™ went further, improving these characteristics while also enhancing the product’s ability to regenerate efficiently.

The breakthrough came with a specially formulated adsorbent material, which was both robust and capable of absorbing larger volumes of contaminants like water, CO2, and other gases. Its fine-tuned pore structure allowed it to selectively adsorb certain molecules while maintaining stability over longer periods of use, even in extreme conditions. This selective adsorption capability was one of Sorbex™’s strongest selling points, allowing it to be used in a wide range of industries beyond petrochemicals, such as air separation and natural gas processing.

Another significant aspect of Sorbex™ was its role in process optimization. The ability to regenerate more effectively meant that the technology could support longer operational cycles, reducing the need for downtime and improving overall efficiency. This made it a favorite for large-scale industrial operations that required not only performance but also economic efficiency. Furthermore, UOP/Honeywell provided extensive support for Sorbex™ users, offering tailored solutions to address specific industry challenges and ensure the technology’s integration into existing systems with minimal hassle.

The combination of improved adsorption, longer operational life, and reduced maintenance needs solidified Sorbex™ as a market leader and forced competitors to raise their game. Over the years, Sorbex™ became synonymous with molecular sieve excellence.

The Shift in the Molecular Sieve Market: The End of the Sorbex™ Monopoly

After 20 years of dominance, what caused the shift in the molecular sieve market? How did the end of Sorbex™’s monopoly unfold?

The shift in the molecular sieve market began as new technologies and competitors emerged. While Sorbex™ remained a top choice, alternatives began to offer similar performance at lower costs, signaling the end of its monopoly.

As the molecular sieve market grew, competition intensified. While Sorbex™ was undisputed for a long period, technological advancements in materials science, as well as market changes, began to chip away at its once-dominant position. One of the main drivers behind this shift was the rise of alternative adsorbents, which began to offer similar levels of performance at a fraction of the cost.

Companies looking to cut costs without sacrificing performance started to explore new adsorbents that had similar adsorption capacities but offered better price points. Additionally, the development of novel materials with even more efficient adsorption capabilities began to challenge the status quo. These new products introduced innovative pore structures and compositions that outperformed traditional molecular sieves in certain applications, particularly in niche markets where specific molecular separations were required.

Another factor contributing to the decline of Sorbex™’s monopoly was the growing interest in sustainability and eco-friendly technologies. As industries became more focused on reducing their carbon footprint and improving energy efficiency, there was a push for molecular sieves that were more sustainable and offered better performance in terms of energy consumption. New technologies emerged that were designed with these concerns in mind, offering even better performance with lower environmental impact.

While Sorbex™ still holds a significant place in the market, the rise of new technologies has led to a more diverse and competitive marketplace. Today, the molecular sieve industry is filled with multiple options that meet varying demands, offering greater flexibility and choice for businesses.

Conclusion

Sorbex™’s 20-year reign transformed the molecular sieve market, but the evolving industry dynamics have given rise to new competitors and technologies. The future of molecular sieves promises more choices and innovation.