Have you ever wondered how the oil industry separates valuable straight-chain alkanes with such precision? Molecular sieves hold the answer.

Molecular sieves have revolutionized the separation of C10 to C18 straight-chain alkanes. This article explores how tailored pore sizes, multi-bed pressure swing systems, and more have transformed alkane purification.

The advancements in molecular sieve technology are nothing short of groundbreaking. These innovations, such as pressure swing adsorption systems, are the backbone of modern alkane separation. Let’s explore how these breakthroughs are pushing the boundaries of separation efficiency.

Precision Engineering: How Tailored Pore Size (5-7Å) Revolutionized C10-C18 Separation Efficiency?

Imagine trying to separate molecules that are nearly identical in size. Sounds impossible, right? But molecular sieves make it happen.

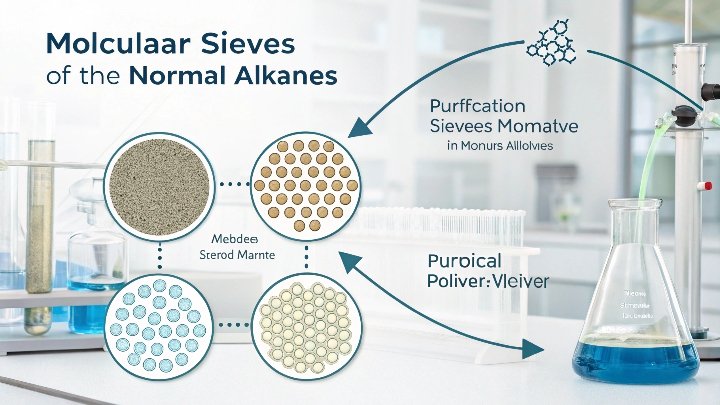

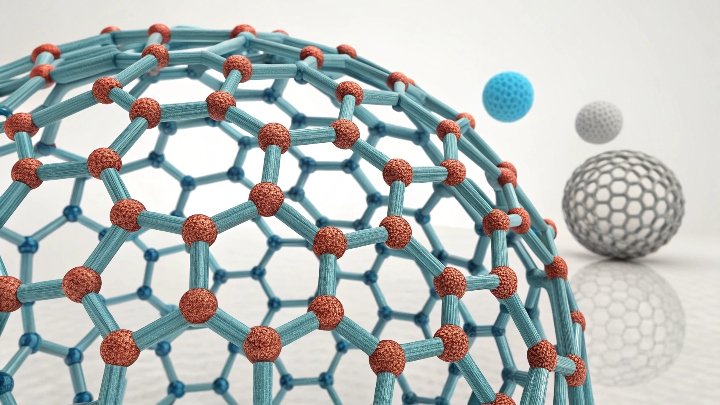

Molecular sieves with tailored pore sizes (5-7Å) are transforming how we separate straight-chain alkanes. This technology is essential for achieving the precise separation of C10 to C18 molecules.

The ability to design molecular sieves with precise pore sizes has been a game-changer in alkane separation. Traditional separation methods couldn’t handle the fine distinctions between molecules in the C10 to C18 range. However, with tailored pore sizes ranging from 5Å to 7Å, molecular sieves can selectively trap certain molecules while allowing others to pass through. This makes it possible to isolate and purify straight-chain alkanes with incredible precision.

Tailoring the pore size is not just about choosing a number; it’s about understanding the molecular structure of the target compound. By optimizing the sieve’s pore size to match the exact size of the molecule, separation becomes far more efficient. For example, alkanes like C10 are separated from higher alkanes like C12, C14, and C18 based on their size differences, which are minuscule but crucial.

This tailored approach significantly reduces the time and energy spent on traditional distillation processes. It also increases throughput and improves the purity of the final product, which is critical for industries like petrochemical production where high purity is non-negotiable.

The Adsorption Breakthrough: Multi-Bed Pressure Swing Systems Achieving >99% Purity

Could a simple change in system design really boost purity to over 99%? Let’s look at how multi-bed pressure swing adsorption systems are doing just that.

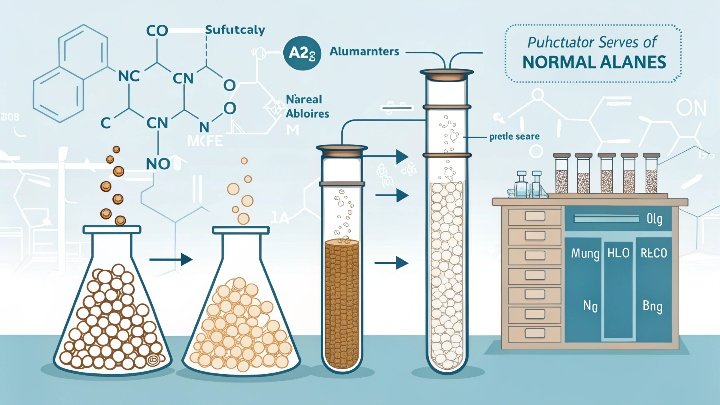

The introduction of multi-bed pressure swing adsorption (PSA) systems has made it possible to achieve purities greater than 99% in C10-C18 alkane separation. This advancement is changing the way refineries operate.

One of the most significant breakthroughs in alkane separation has been the advent of multi-bed pressure swing adsorption (PSA) systems. This technology allows for continuous cycling of molecular sieve beds, which improves both efficiency and stability in the separation process. In traditional single-bed systems, once the adsorbent becomes saturated, it needs to be replaced or regenerated, which can cause downtime. Multi-bed systems, however, cycle between beds, ensuring that one bed is always regenerating while the others are actively separating alkanes.

This continuous cycling ensures that high purity levels, greater than 99%, can be consistently achieved. The ability to regenerate the beds between cycles reduces the need for costly downtime, making it an economically viable option for refineries. In fact, the efficiency improvements of multi-bed systems have led to significant reductions in operational costs over time.

Moreover, the precision in adsorption also allows refineries to isolate specific alkane fractions. This is particularly useful for high-value products like aviation fuels or specialized petrochemical intermediates. In short, multi-bed PSA systems have proven to be a breakthrough that not only increases purity but also enhances the overall performance and cost-effectiveness of alkane separation.

From Linear Selectivity to Thermal Stability: ZSM-5 vs SAPO-11 Molecular Sieves Performance Showdown

What happens when you pit two highly advanced molecular sieve materials against each other? The ZSM-5 and SAPO-11 comparison reveals a lot about molecular sieve performance.

ZSM-5 and SAPO-11 are both essential materials in alkane separation. Let’s see how their linear selectivity and thermal stability stack up against each other in real-world applications.

ZSM-5 and SAPO-11 are two of the most commonly used molecular sieves for alkane separation. However, they each offer unique advantages depending on the specific requirements of the separation process.

ZSM-5 is known for its exceptional linear selectivity. It has a unique pore structure that allows it to selectively adsorb straight-chain molecules while rejecting branched-chain and cyclic molecules. This makes ZSM-5 ideal for applications where separating linear alkanes from other types of hydrocarbons is a priority. It also has excellent thermal stability, meaning it can withstand high temperatures during the separation process without degrading. This thermal stability is crucial in industrial settings, where temperatures can fluctuate and the material must maintain consistent performance.

On the other hand, SAPO-11 is a more specialized material that excels in separating alkanes within a specific range, especially those in the C10 to C18 range. It has a higher resistance to thermal degradation compared to other molecular sieves and performs well in high-temperature environments. However, its linear selectivity is not as high as ZSM-5’s, which means it is better suited for applications where both linear and branched-chain alkanes need to be separated at similar levels.

Both materials have their strengths and can be used effectively depending on the specific needs of the separation process. Understanding their differences is key to selecting the right molecular sieve for optimal performance in alkane purification.

Conclusion

The advancements in molecular sieve technology, such as tailored pore sizes, multi-bed PSA systems, and innovations in material selection, have drastically improved the efficiency and purity of C10-C18 alkane separation. These breakthroughs are essential for the future of refining and petrochemical production.