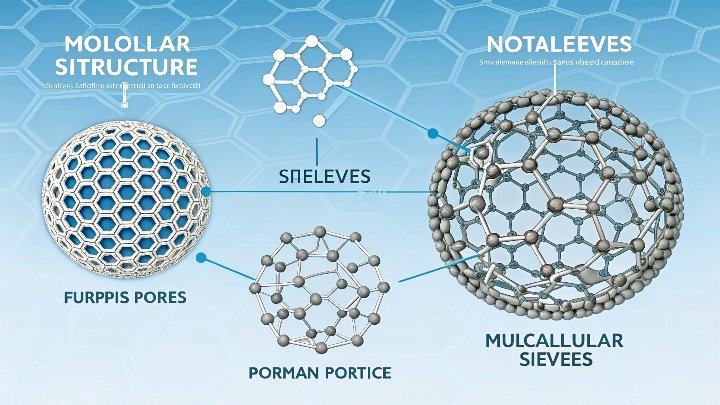

Eager to control gas purity but worried about rising impurities? I see 13X molecular sieves as the answer to your challenges.

I believe 13X molecular sieves transform gas purification processes. They remove CO2, H2S, and other impurities with ease, which helps many industries improve air quality and reduce emissions. Their regeneration features save costs and promote sustainability.

I want to share why these sieves have become central to my work. I have seen how they adapt to different industrial needs. I hope my experiences will help you see their incredible potential.

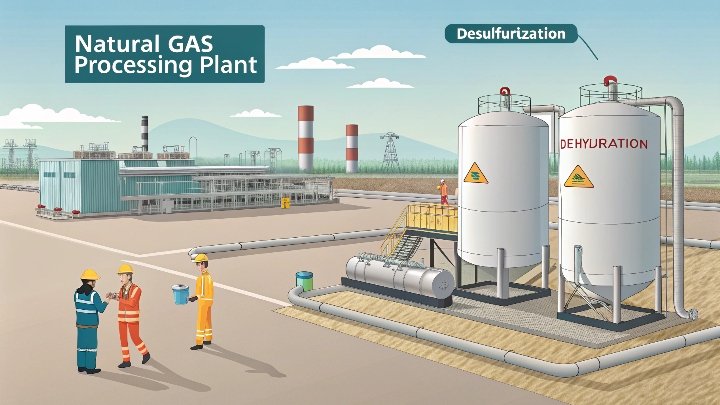

Natural Gas Processing: Removing Impurities with Precision?

Solving natural gas purity challenges can feel intimidating. I trust 13X molecular sieves to handle this step with control and accuracy.

I find 13X molecular sieves vital for removing CO2, H2S, and moisture from natural gas. They allow operators to reduce corrosion and keep pipelines free from clogs. Their strong adsorption power cuts costs and eases maintenance.

Digging Deeper into Natural Gas Processing with 13X Molecular Sieves

I see natural gas processing as a field that requires a precise approach. My work in this area taught me that small impurities can cause big problems. Corrosion inside pipelines leads to safety risks. Blockages can cause downtime. To address these problems, we need dependable strategies. That is why 13X molecular sieves have become my top recommendation for many projects. They have a strong ability to adsorb CO2 and H2S, which are the most troublesome impurities in natural gas streams. Below is a simple table showing the key reasons I rely on 13X molecular sieves:

| Key Point | Explanation |

|---|---|

| High Adsorption Capacity | They capture CO2 and H2S, preventing corrosion in pipelines |

| Regenerability | Their structure allows repeated reuse with minimal performance loss |

| Ease of Integration | They can fit into existing processing units with little modification |

I have experimented with different adsorbents, but 13X sieves stood out. They are stable and do not require excessive energy to regenerate. This is essential for cost management. When plants run large volumes of gas, frequent regeneration can strain budgets. By choosing 13X sieves, I see less downtime, which boosts productivity.

I also pay attention to safety. Natural gas must meet strict standards before entering pipelines and distribution networks. If CO2 or H2S levels exceed certain thresholds, that can lead to pipeline corrosion or even public health risks. 13X sieves help keep impurities below regulated limits. This prevents harmful leaks and extends infrastructure life. By avoiding corrosion, companies do not need frequent pipe replacements or expensive repairs.

I have also noticed how easy it is to monitor the performance of these sieves. Operators can install measuring instruments to track breakthrough points. Once the sieve becomes saturated, it can be regenerated using heat or pressure swings. This process is straightforward and does not degrade the sieve’s structure. Many colleagues tell me they appreciate the consistency of 13X sieves. Their reliability saves time and lowers operational anxiety.

I believe 13X molecular sieves remain the best choice for natural gas purification. They help me meet stringent quality standards. They also reduce costs and downtime. Their high adsorption capacity and easy regeneration make them a solid pillar of modern gas processing operations.

Air Separation: Oxygen and Nitrogen Purification Made Efficient?

Air separation can look complicated, yet I have found 13X molecular sieves to simplify it.

I consider 13X molecular sieves to be the core of many air separation units. They allow me to purify oxygen and nitrogen streams without large energy costs. Their design suits the demands of continuous processes.

Exploring 13X Molecular Sieves in Air Separation

When I first learned about air separation, I saw that many factories rely on cryogenic methods. These methods separate oxygen and nitrogen by cooling air to extremely low temperatures. While that approach is effective, it can also be costly and power-intensive. That is where 13X molecular sieves can step in. Their pore structure allows them to adsorb or exclude certain gases with a high level of selectivity. This helps optimize oxygen or nitrogen recovery.

I like to split the air separation process into several key steps. First, the incoming air goes through filters to remove dust and other small particles. Then it moves into an adsorption tower filled with 13X sieves. These sieves capture moisture and other impurities. By drying the incoming air, the rest of the process runs more smoothly. Further steps might include additional separation strategies to isolate oxygen and nitrogen. However, 13X sieves help lay the groundwork by cleaning the air stream.

In some applications, like Pressure Swing Adsorption (PSA) or Vacuum Swing Adsorption (VSA), I see how 13X molecular sieves have a direct role in focusing on certain gas components. For example, nitrogen might be adsorbed under pressure, leaving high-purity oxygen in the output. Then, during the depressurization phase, the nitrogen is released from the sieve. This cycle repeats many times. The robust structure of 13X sieves handles this stress well. They are not easily damaged by constant pressure changes. They also do not degrade quickly, which keeps operating costs low.

Another benefit is how I can integrate 13X sieves into both large and small air separation systems. In big industrial plants that supply hospitals or steelmakers, stable adsorbent performance is crucial. I have seen these sieves stand up to heavy use, day after day, without losing efficiency. In smaller setups, like on-site generators, 13X sieves can also help produce oxygen or nitrogen at consistent purity levels. This flexibility makes them valuable for companies of different sizes.

I often reflect on how 13X sieves compare to older adsorbent materials. Some older options might have lower selectivity, meaning they cannot fully separate oxygen or nitrogen. Others might degrade faster, forcing frequent replacements. In my experience, 13X stands out for its selectivity and resilience. Because the regeneration process uses simple steps, like pressure or temperature swings, the cost to keep these sieves running is not overwhelming. This reliability and affordability help me and my clients stay competitive in the market.

Environmental Applications: Cleaning Air and Capturing Pollutants?

Protecting our planet is a big priority for me. I see 13X molecular sieves as a powerful way to trap pollutants and keep our air clean.

I use 13X molecular sieves in pollution control systems. They capture volatile organic compounds (VOCs) and other harmful emissions. Their robust structure helps reduce atmospheric contamination.

Unpacking 13X Molecular Sieves for Environmental Protection

I have watched industrial emissions become a major concern for many people. Factories and power plants often release harmful gases that threaten air quality. This is where 13X molecular sieves come into play. They excel at capturing molecules like VOCs, sulfur compounds, and nitrogen oxides, depending on the process conditions. My work in this area started when I helped design a pilot system that used 13X sieves to remove VOCs from an exhaust stream. I was surprised by the consistent results. Even under fluctuating temperatures and flow rates, the sieves maintained their performance.

I break down these applications into a few critical functions. First, 13X sieves can help remove pollutant gases from industrial exhausts before they reach the environment. This step is essential for meeting emission standards. Second, 13X sieves can handle odor control in facilities that process waste or chemicals. By adsorbing sulfur compounds and other odor-causing molecules, these sieves keep surrounding communities happier. Third, 13X sieves can be regenerated and used many times, which reduces waste. This cyclical approach aligns with sustainability goals.

One time, I visited a plant that struggled with constant complaints about odors. They processed sulfur-rich chemicals and needed a robust system to keep emissions in check. By installing a 13X-based adsorption stage, they saw an immediate drop in odor problems. The local residents noticed the improvement, and the plant avoided fines. This story showed me how powerful these sieves are in real-world conditions.

I also care about climate issues. While 13X sieves do not remove carbon dioxide on the same scale as specialized carbon capture materials, they still trap CO2 in smaller volumes. This matters when facilities want to refine their carbon footprint. Every molecule of CO2 removed contributes to emission targets. If we combine these sieves with other capture technologies, we can form a multi-layer approach to pollution control. That synergy can help industries meet environmental mandates.

In addition, I see potential for 13X sieves in new technologies. Emerging trends in carbon capture and storage might use advanced adsorbent materials. 13X could complement these solutions by serving as a pre-filtration step. By removing moisture, sulfur compounds, or large hydrocarbons, the overall system might work better. This kind of layered approach is something I am investigating for future projects. I like to keep pushing boundaries by combining known adsorbents with newer ideas.

From where I stand, 13X molecular sieves deserve much of the spotlight. Their ability to adapt to many pollution scenarios makes them a game-changer. They offer cost-effective performance, easy regeneration, and a proven track record. These qualities make them ideal for large factories and smaller facilities alike. With growing pressure to meet strict emission rules, I find that 13X sieves offer a reliable route to cleaner air.

Conclusion

I see 13X molecular sieves as a key driver for cleaner processes and better air. They remove impurities and keep industries sustainable.