Struggling with impurities ruining your sensitive electronic components? This contamination leads to defects and massive losses. Molecular sieves[^1] offer a precise solution, ensuring the ultra-high purity[^2] your processes demand.

Molecular sieves[^1] are crucial for the electronic specialty gas[^3] industry because their unique porous structure selectively adsorbs water and other contaminants. This ensures the ultra-high purity[^2] required for manufacturing semiconductors and LEDs, preventing defects and improving production yields.

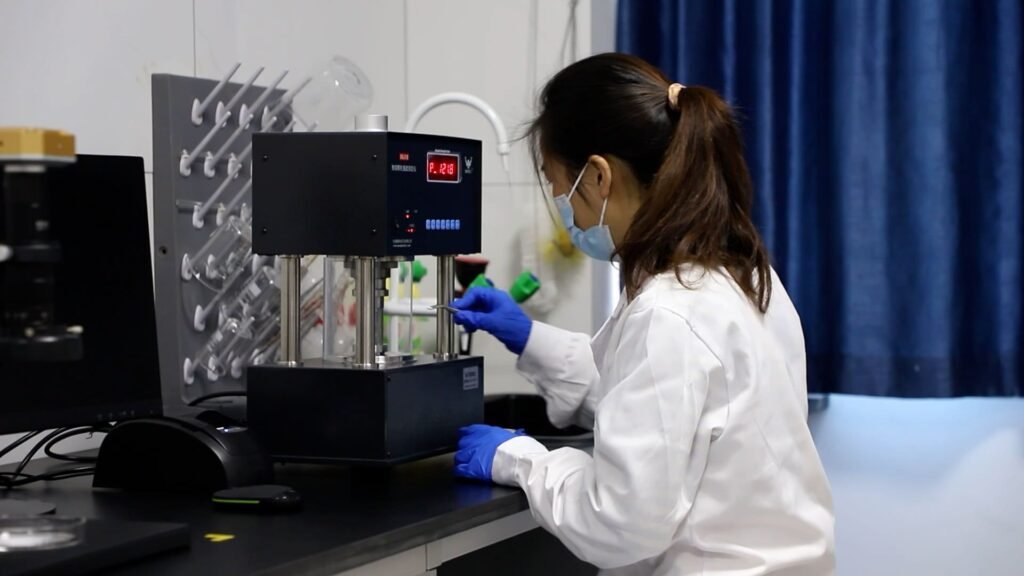

As a manufacturer of high-performance molecular sieves[^4], I've seen firsthand how critical purity is. We work with global brands that simply cannot afford contamination. The technology behind making a perfect microchip is incredible, but it's also incredibly fragile. Even a few parts per million of moisture can bring a multi-million dollar production line to a halt. This is where our products become the unsung heroes of the electronics world. We're not just making adsorbents; we're providing the foundation for reliability. Let's explore exactly how this works and why it's so important for your business.

Why is Ultra-High Purity So Critical for Electronic Gases?

You're working with sensitive electronic components, where the slightest impurity can cause a major failure. An entire batch of microchips can become useless from trace moisture. Purity is non-negotiable.

Ultra-high purity is critical because contaminants like water or CO₂ react with materials during semiconductor manufacturing. This causes device defects, alters electrical properties, and drastically reduces yields. Purity ensures process stability and final product reliability.

In my 20 years in the chemical industry, I've learned that some materials are more demanding than others. Electronic specialty gases are at the top of that list. These gases are the lifeblood of modern electronics. They are used in processes like cleaning, etching, film deposition, and doping. Each step is a delicate dance at the microscopic level. Introducing an unwanted molecule, like water, is like throwing a rock into a Swiss watch. It disrupts everything. For example, moisture in a deposition gas can lead to a faulty insulating layer, causing a short circuit. That's why our clients in the semiconductor and LED industries demand purity levels that are almost absolute.

The Role of Gases in Microfabrication

Electronic gases are not just background materials; they are active participants. Gases like silane (SiH₄) are used to deposit silicon layers, while others like ammonia (NH₃) are used for creating nitride films. These processes build the complex, layered structures of a microchip. The gas itself becomes part of the final product. Any impurity in the gas can therefore become a permanent defect in the chip.

Impact of Impurities on Key Processes

The impact of contamination varies by process, but it is always negative. We've seen how different impurities can cause specific problems. Understanding this helps us guide our partners to the right purification solution.

| Process | Common Gas Used | Key Impurity | Negative Impact |

|---|---|---|---|

| Etching | CF₄, SF₆ | Water (H₂O) | Alters etch rate, causes uneven surfaces |

| Deposition | SiH₄, NH₃ | Water (H₂O) | Creates oxide defects, poor film quality |

| Doping | B₂H₆, PH₃ | Oxygen (O₂) | Changes electrical properties, reduces performance |

| Cleaning | NF₃ | CO₂ | Leaves residue, incomplete surface cleaning |

This is why we invested RMB 8 million in a fully automated production line. It ensures our molecular sieves have the stable, reliable quality needed to remove these specific impurities effectively, every single time.

How Do Molecular Sieves Achieve Such Precise Purification?

You know you need to remove moisture, but how do you do it without affecting the valuable specialty gas? Using the wrong desiccant could be ineffective or even worse. Molecular sieves[^1] act like a perfect filter.

Molecular sieves[^1] have a uniform, crystalline structure with tiny pores of a precise size. They work by trapping small molecules like water through adsorption[^5], while allowing the larger electronic gas molecules to pass through freely. This size-exclusion principle is highly effective.

The magic of molecular sieves is in their structure. Think of them as microscopic sponges, but with one key difference: all the holes are exactly the same size. We create these synthetic crystals in our factory, and we can control the size of these openings, or "pores," with incredible precision. For instance, our 3A molecular sieve[^6] has pores that are 3 angstroms in diameter. A water molecule is about 2.8 angstroms, so it fits inside perfectly and gets trapped. However, a gas molecule like ethanol or the specialty gas silane (SiH₄) is larger than 3 angstroms, so it can't enter the pores and simply flows past. This is the core of their selective power.

The Science of Adsorption

Adsorption isn't a chemical reaction. It's a physical process where molecules stick to a surface. The massive internal surface area of a molecular sieve (hundreds of square meters per gram) provides countless sites for water molecules to cling to. Because this attraction is strong, molecular sieves can pull moisture content down to extremely low levels, often below 0.1 parts per million. This is what we call achieving a very low "dew point[^7]," which is essential for sensitive electronic gases.

Choosing the Right Sieve for the Job

Different gases require different sieves. The choice depends on the size of the gas molecule you want to purify and the impurity you need to remove.

| Sieve Type | Pore Size (Angstroms) | Molecules Adsorbed | Molecules Excluded (Purified Gas) |

|---|---|---|---|

| 3A | 3 Å | H₂O, NH₃ | SiH₄, C₂H₄, most specialty gases |

| 4A | 4 Å | H₂O, CO₂, C₂H₄ | Larger hydrocarbons, SF₆ |

| 13X | 10 Å | H₂O, CO₂, O₂, larger molecules | Used when co-adsorption[^5] is needed |

Our factory uses a granulator-based forming process, not the old sugar-coating pan method. This results in beads with more uniform size, higher strength, and much lower dust. For high-purity gas streams, minimizing dust is just as important as removing moisture.

What Makes Molecular Sieves the Top Choice for the ESG Industry?

Other drying methods exist, so why is the industry standardizing on molecular sieves? Choosing a less reliable method could put your production and reputation at risk. Molecular sieves[^1] offer a unique combination of advantages.

Molecular sieves[^1] are the top choice due to their high selectivity, extreme drying capability, and excellent stability. They can achieve the ultra-low dew point[^7]s required for electronic gases, a feat other desiccants cannot consistently match, while ignoring the valuable product gas.

When we talk to new OEM partners or distributors, they often ask what makes our molecular sieves better than other purification technologies. The answer lies in performance under demanding conditions. Cryogenic purification (cooling a gas until impurities freeze out) is effective but extremely energy-intensive. Chemical scrubbers can work, but they are often consumable and can introduce their own contaminants. Molecular sieves[^1] hit the sweet spot. They are highly efficient, regenerable (meaning they can be reused many times), and offer unparalleled selectivity. This combination of features makes them the most cost-effective and reliable solution for achieving the "five nines" (99.999%) purity or higher that the electronics industry demands.

Beyond Just Water Removal

While water is the primary enemy, other impurities like carbon dioxide (CO₂) and oxygen (O₂) are also major concerns. This is where more advanced molecular sieves come into play. Our 13X-APG (Air Pre-purification Grade) molecular sieve is specifically designed for this. It has a larger pore size (10 angstroms) and a high capacity for co-adsorbing both water and CO₂ from gas streams. This is vital in air separation units that feed pure nitrogen or oxygen to fabrication plants. For even more demanding jobs, like removing trace sulfides from biogas to produce biomethane, we offer our 13X-HP (High Performance) product, which is engineered for maximum selectivity.

Integration into Multi-Stage Systems

In the real world, no single technology does it all. Molecular sieves[^1] are often the heart of a larger, multi-stage purification system. A gas stream might first pass through a catalytic converter to break down certain impurities, then through a molecular sieve bed for deep drying and CO₂ removal.

| Purification Method | Primary Target | Pros | Cons |

|---|---|---|---|

| Molecular Sieves | H₂O, CO₂, Polar Molecules | High selectivity, deep drying, regenerable | Can be fouled by heavy hydrocarbons |

| Cryogenic Separation | All impurities | Very high purity achievable | Very high energy cost, complex equipment |

| Chemical Scrubbers | Acidic gases (H₂S, CO₂) | High capacity for specific targets | Consumable, potential for downstream contamination |

As you can see, molecular sieves provide the most balanced and versatile performance, making them the cornerstone of purification. As an OEM/ODM supplier, we help brands integrate our high-quality sieves into their systems to provide their customers with a complete, reliable solution.

Conclusion

For ultra-pure electronic specialty gas[^3]es, molecular sieves are not just an option. They are the essential foundation for quality, yield, and innovation in the semiconductor and electronics industry.

[^1]: Explore the science behind molecular sieves to understand their critical role in achieving ultra-high purity. [^2]: Discover why ultra-high purity is essential for preventing defects in semiconductor production. [^3]: Learn about electronic specialty gases and their importance in modern electronics manufacturing. [^4]: Discover the advantages of high-performance molecular sieves in achieving gas purity. [^5]: Explore the process of adsorption and its significance in purifying gases. [^6]: Understand the unique properties of the 3A molecular sieve and its applications. [^7]: Learn about dew point and its critical role in maintaining gas purity.