Your compressed air system is underperforming, and you suspect the molecular sieves[^1]. This can damage equipment and ruin products, but you’re not sure if it's time for a replacement[^2].

The most common signs that your molecular sieves[^1] need replacing are a rising dew point[^3] in the outlet air, shorter adsorption cycles[^4], increased energy needed for regeneration, and physical breakdown of the sieve beads, such as powdering or clumping. Any one of these is a strong indicator.

Knowing these signs is one thing, but understanding what they mean for your operation is another. A small issue with your molecular sieves[^1] can quickly become a major, expensive problem for your entire compressed air system if you don't act.

Let's break down each of these signals. This way, you can diagnose your system with confidence and avoid unnecessary costs. I want you to be able to spot the problem early and make the right call every time.

Is Your Compressed Air Dew Point Suddenly Too High?

Is your final product quality dropping? You're seeing moisture where it shouldn't be, causing rust or contamination. Your outlet dew point[^3] is your first and most important clue.

A rising dew point[^3] in your compressed air means the molecular sieves[^1] are no longer adsorbing enough water. If the moisture content exceeds your process specifications, the sieves are saturated or damaged and likely need to be replaced to protect your equipment and products.

In my 20 years in the chemical industry, the dew point[^3] is the first thing I ask clients to check. It's the most direct measure of your air dryer's performance. Dew point is simply the temperature at which water vapor in the air turns back into liquid water. For most industrial applications, you need a very low dew point[^3], often around -40°C, to guarantee your air is perfectly dry.

When the molecular sieves[^1] are fresh and working correctly, they easily achieve this target. But as they age or get contaminated, their ability to grab water molecules fades. A reading of -30°C instead of -40°C might not seem like much, but it represents a significant increase in water content. This moisture can cause corrosion in pipes, freeze-ups in cold environments, and spoil sensitive products. It’s a clear signal the sieves are failing.

How to Interpret Dew Point Readings

| Dew Point Reading | Sieve Performance | Action Required |

|---|---|---|

| Meets Specification (-40°C) | Optimal | Continue routine monitoring. |

| Slightly Above Spec (-30°C) | Degrading | Investigate regeneration settings and check for leaks. |

| Significantly Above Spec (-20°C) | Failed | The sieves have lost capacity. Plan for immediate replacement[^2]. |

Are Your Regeneration Cycles Getting Shorter and Shorter?

Does your air dryer seem to be working overtime? This constant cycling increases energy costs and puts more wear on your system’s valves, but you can’t seem to stop it.

If your dryer, which used to run an 8-hour adsorption cycle, now needs regeneration every 3 or 4 hours to maintain the same dew point[^3], its effective capacity has been cut in half. This means the molecular sieve bed is saturated or damaged and needs changing.

Most industrial air dryers use a twin-tower design[^5]. One tower is online, drying the air, while the other is offline, regenerating its molecular sieves[^1]. The "cycle time" is how long one tower can stay online before it becomes saturated with water and needs to switch. A new, healthy bed of 4A molecular sieves[^1] might run for 8 to 10 hours.

I remember a client whose energy bills for their compressor room suddenly spiked. They couldn't figure it out until we checked the dryer's cycle logs. The switchover frequency had nearly doubled. The sieves were working twice as hard for the same result. This happens because the microscopic pores inside the sieve beads get clogged over time. Contaminants like compressor oil can coat the beads, or some water molecules can become permanently trapped. This reduces the active surface area available to adsorb moisture, so the bed fills up much faster.

The Economic Impact of Shorter Cycles

| Cycle Time | Switches per Day | Estimated Energy Cost Increase | Sieve Health |

|---|---|---|---|

| 8 hours | 3 | Baseline | Healthy |

| 6 hours | 4 | +33% | Degrading |

| 4 hours | 6 | +100% | Critical / Needs Replacement |

Does Regeneration Now Require More Heat or Time Than Before?

You're following the standard regeneration procedure, but it's not working like it used to. You find yourself wasting energy and time trying to revive underperforming sieves.

When you have to increase the regeneration temperature[^6] or extend the heating and purging time just to get the sieves back to a functional state, it’s a strong signal they are nearing the end of their life. At this point, replacement[^2] is often more economical.

Regeneration is designed to release the water captured by the sieves so they can be used again. In a heated dryer, this is done by passing hot, dry air through the bed. However, if the sieves are contaminated with oil from the compressor, that oil can "coke" or burn onto the surface at high temperatures, permanently blocking the pores.

Another issue is something we call "hydrothermal aging[^7]." Over thousands of cycles, the repeated exposure to high-temperature steam (the water being driven off) can slowly damage the sieve's internal crystal structure. This is a natural aging process, but it means the sieve permanently loses some of its adsorption capacity. You'll notice you have to "cook" the bed longer or at a higher temperature to get the dew point[^3] back down, and even then, the performance is not what it once was. Our sieves are designed for high stability to resist this, but no sieve lasts forever.

Diagnosing Regeneration Problems

| Symptom | Potential Cause | Our Recommendation |

|---|---|---|

| Needing higher regeneration temps | Minor oil coking or hydrothermal damage. | Monitor performance closely and plan for replacement[^2]. |

| Needing longer purge/heating times | Heavy contamination[^8] or partial pore blockage. | Check your pre-filters[^9] immediately and schedule a change-out. |

| Performance not restored after regen | Severe damage or end-of-life. | The sieves are finished. Immediate replacement[^2] is required. |

Have You Found Dust or Clumps in Your Molecular Sieve Bed?

You're doing a routine inspection and find something wrong with the sieve beads themselves. This dust can travel downstream, clog filters, and damage sensitive pneumatic equipment.

Finding powdered dust or solid clumps in your molecular sieve vessel is a critical failure signal. These conditions severely restrict airflow, increase pressure drop[^10], and mean the bed must be replaced immediately to prevent further damage to your entire air system.

This is perhaps the most serious sign because it points to a physical breakdown of the material. There are two forms this takes, and both are bad news.

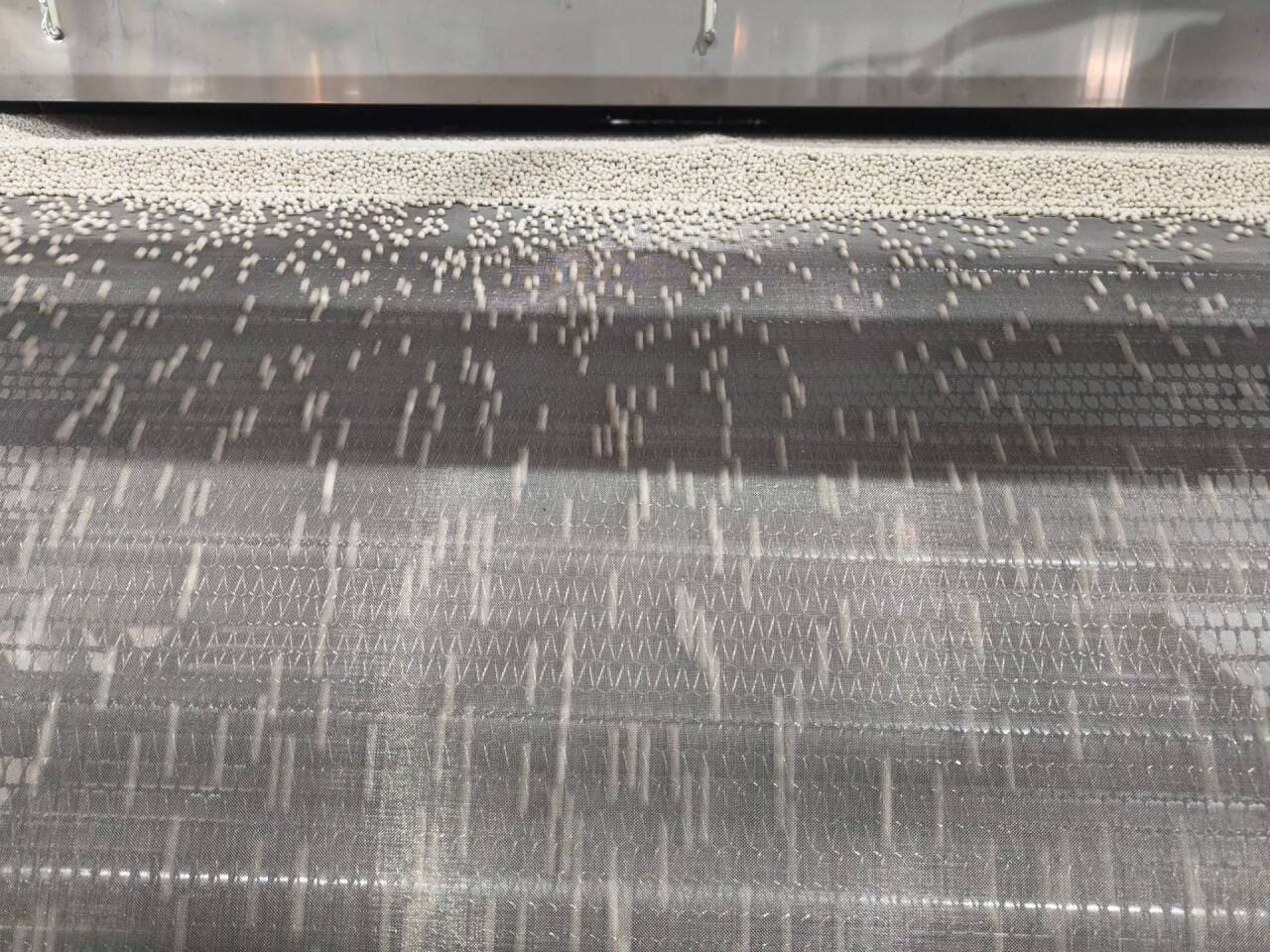

Sieve Dusting and Powdering

This happens when the beads physically break down. It can be caused by low-quality sieves with poor crush strength, high air velocity that tumbles the beads, or system vibrations. The resulting dust increases the pressure drop across the bed, making your compressor work harder. Worse, this fine dust can escape the vessel and contaminate your entire air network. This is why we invested RMB 8 million in our granulator-based forming process. It produces beads with superior mechanical strength and uniform size, which dramatically reduces the risk of powdering compared to older methods.

Caking and Clumping

This is what happens when liquid water hits the molecular sieve bed. The rapid adsorption of liquid generates a huge amount of heat, which can fuse the beads and their binding agent into a solid, concrete-like mass. This is often caused by a failure in the upstream water separator or coalescing filter. This solid mass creates channels where the compressed air can bypass the sieve bed entirely, rendering your dryer completely useless. It's an emergency situation that requires an immediate shutdown and replacement[^2].

Conclusion

Monitoring dew point[^3], cycle times, regeneration effort, and physical condition will tell you exactly when to act. Proper pre-filtration and correct operation will maximize the life of your sieves.

[^1]: Understanding molecular sieves is crucial for maintaining your compressed air system's efficiency. [^2]: Find out the key indicators for timely replacement to avoid system failures. [^3]: Learn how dew point affects product quality and system performance. [^4]: Explore how adsorption cycles impact energy efficiency and system longevity. [^5]: Explore the benefits of twin-tower designs for efficient air drying. [^6]: Find out the best practices for maintaining effective regeneration temperatures. [^7]: Understanding hydrothermal aging can help you manage sieve lifespan effectively. [^8]: Explore the effects of contamination on sieve performance and system health. [^9]: Learn how pre-filters can enhance the performance and longevity of your sieves. [^10]: Learn how pressure drop can impact efficiency and performance.