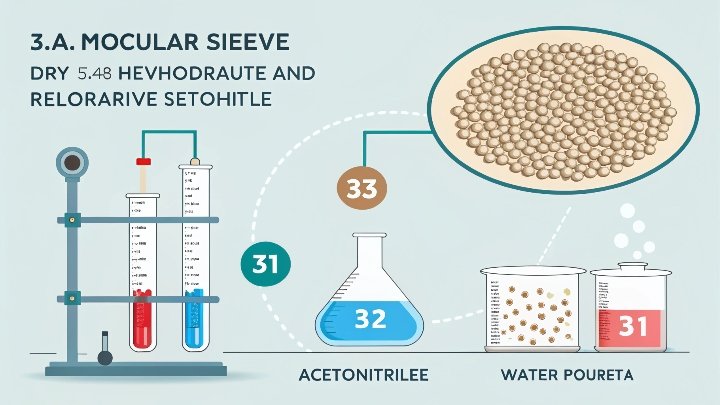

I once struggled with low reaction yields caused by trace moisture in acetonitrile. That problem made me anxious and unsure. Then I discovered the power of 3Å molecular sieves.

This material removes water so acetonitrile can reach optimal dryness. It is a porous adsorbent that traps water while leaving acetonitrile purity intact. It is reliable, reusable, and simple to handle.

I tried other drying methods before, but they were too complex or introduced contaminants. That is why I trust 3Å molecular sieves. Let me share more details below.

Why Use a 3Å Molecular Sieve for Drying Acetonitrile?

I used to ask if there was a straightforward way to remove water from acetonitrile. I was tired of methods that required extra steps or caused byproducts.

It is best to use a 3Å molecular sieve because it selectively adsorbs water. It works well at moderate temperatures and can be regenerated easily. It also preserves acetonitrile’s quality and does not produce harmful waste.

The Nature of 3Å Molecular Sieve

I know that 3Å molecular sieve has pore openings of about 3 angstroms. This size is perfect for trapping water molecules, which are smaller than many solvent molecules. Water molecules slip into these pores, and they get held by adsorption forces. These forces are mostly van der Waals interactions. So the sieve locks water inside its structure.

Adsorption Performance and Selectivity

A big advantage of the 3Å molecular sieve is its selectivity. It focuses on water rather than other common solvents. This is important in labs where you need consistent solvent purity. If you use a less selective approach, you could lose valuable solvents or introduce side reactions. The 3Å pore structure helps isolate water while leaving other molecules free.

Regeneration and Reusability

Another critical factor is reusability. I appreciate that 3Å molecular sieves can be heated at moderate temperatures to drive off the water. That means I can reuse them. This is helpful when reducing costs or working on a tight schedule. By drying sieves in an oven or vacuum setup, you restore their adsorption capacity. The ability to do this multiple times makes them a reliable option in the long run.

Comparison with Other Drying Methods

Sometimes, people use drying agents like calcium chloride or magnesium sulfate. Those can work, but they often add extra steps or create dust and residues. In contrast, 3Å molecular sieves do not pollute the solvent. They also do not break down under normal conditions. This stability is why many labs choose them.

Below is a simple table that compares different drying methods:

| Drying Method | Complexity | Residues or Byproducts | Reusability |

|---|---|---|---|

| 3Å Molecular Sieve | Low | No | Yes |

| Calcium Chloride | Moderate | Possible dust | Limited |

| Magnesium Sulfate | Moderate | Possible fine solids | Limited |

| Vacuum Distillation | High | No | Somewhat |

I have relied on 3Å molecular sieves for deep dehydration in acetonitrile because the method is easy and produces clean results. When water content is too high, reactions can fail or form unwanted side products. This is common in sensitive reactions like Grignard or moisture-sensitive coupling reactions. By using 3Å molecular sieves, I avoid setbacks. I also keep my reaction yields as high as possible.

Step-by-Step Guide to Drying Acetonitrile with a 3Å Molecular Sieve

I first thought that using a molecular sieve would be hard. But it is simpler than other methods. Let me outline the process.

The core steps include preparing the acetonitrile, activating the 3Å molecular sieve, combining them, and confirming dryness. This process is straightforward and does not need complicated tools.

Preparing Acetonitrile

I start by inspecting the acetonitrile for visible contamination. If it looks cloudy or contains solid particles, I filter it. I want to remove possible impurities before introducing the sieve. Then I check the approximate water content. Some labs use a Karl Fischer titrator or other tests. If the water content is too high, I may perform a preliminary dehydration step with basic drying agents, but only if it is necessary.

Activating the 3Å Molecular Sieve

Next, I ensure the 3Å molecular sieve is activated. That means removing any moisture it has previously adsorbed. I do this by heating it in an oven at around 200–300°C for a few hours. Some people use a vacuum oven to accelerate moisture removal. Then I place the freshly activated sieve in a desiccator to cool it. This step is important because a warm sieve can adsorb moisture from the air if left exposed too long.

Mixing Acetonitrile with the Sieve

After the sieve is cool, I transfer it to a dry container. I add the acetonitrile in a ratio that will handle the estimated water content. A common guideline is to use at least 10-20% by weight of sieves relative to the solvent volume. I seal the container to prevent ambient moisture from getting in. Then I let the mixture sit for several hours or overnight, depending on how dry I want it. Gentle stirring can speed up the process.

Checking Dryness

When the contact time is done, I check dryness. One quick check is clarity and the absence of haze. But I prefer a more precise test like Karl Fischer titration. This test measures water content down to parts per million. If the water level is still not as low as I need, I add fresh sieve or increase contact time. Acetonitrile can reach very low water concentrations with repeated exposure to fresh or reactivated sieves.

Here is a short table that outlines each step:

| Step | Action | Time Required |

|---|---|---|

| Filter and Inspect Acetonitrile | Remove solids or cloudiness | A few minutes |

| Activate 3Å Sieve | Heat at 200–300°C | 2–4 hours |

| Cool Sieve in Desiccator | Prevent re-adsorption of water | 30 minutes |

| Mix Sieve with Acetonitrile | Stir or soak | Several hours |

| Test Dryness | Use titration or visual check | 10–20 minutes |

This process is efficient. It also avoids messy byproducts. The 3Å molecular sieve stays in bead or pellet form, so it is easy to remove by simple decantation or filtration. I like that this approach keeps everything neat. Traditional drying salts can leave fine particulates that I find tedious to filter out. With 3Å molecular sieves, you preserve solvent quality without introducing extra problems.

Benefits and Applications of Dry Acetonitrile in the Lab

I recall how water in acetonitrile caused unexpected side reactions in my first research project. That experience made me search for a better drying solution.

Dry acetonitrile offers stronger reproducibility in reactions. It also improves yields in moisture-sensitive syntheses and ensures reliable analytical results. Labs depend on consistent solvent quality.

Analytical Chemistry and Chromatography

In my work with analytical chemistry, I see how water can change the retention times in high-performance liquid chromatography (HPLC). Water in the solvent can shift polarity, so it can alter separation profiles. When I dry acetonitrile thoroughly, I maintain consistent chromatographic conditions. This consistency is important for accurate analysis and reproducible results. Many labs handle large sample volumes, so stable solvent composition speeds up method development and reduces error.

Chemical Synthesis and Reaction Efficiency

Dry acetonitrile helps a wide range of reactions that might fail if water is present. For instance, water-sensitive reagents like Grignard compounds or certain coupling agents can decompose in moist environments. That is when I rely on ultra-dry acetonitrile to keep these reactions stable. I also see big gains in reaction yield and product purity. Dry conditions can shorten reaction times or lower the chance of side product formation.

Sample Preparation

In sample preparation, especially for mass spectrometry, water can cause ionization problems or unexpected signals. So I prefer using dry acetonitrile. It reduces background noise and improves detection limits. In some assays, even small amounts of water can shift the mass-to-charge ratio or produce adducts that complicate data interpretation. By using a 3Å molecular sieve, I can store large quantities of acetonitrile in a dry state for extended periods.

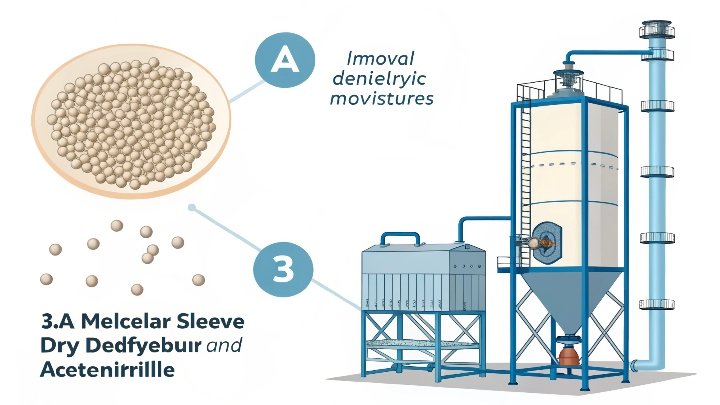

Industrial-Scale Applications

On an industrial scale, consistent solvent quality is vital. I have seen how big plants incorporate CNM 3A molecular sieves into their processes. They set up large adsorption columns or fixed beds to maintain a continuous stream of dry acetonitrile. Regeneration procedures are scheduled to keep downtime low. This approach helps them produce consistent chemical intermediates and ensures their production lines run smoothly.

Below is a table that summarizes a few applications and the potential benefits:

| Application | Benefit | Explanation |

|---|---|---|

| HPLC and Analytical Methods | Stable retention times | Reduced polarity shifts and more accurate results |

| Grignard and Sensitive Reactions | Higher yields | Less reagent decomposition and side reactions |

| Mass Spectrometry | Better signal clarity | Fewer background ions and contaminants |

| Large-Scale Chemical Production | Consistent solvent quality | Continuous adsorption and easy regeneration |

This table barely covers the versatility of dry acetonitrile. I have noticed that once you know how to keep it dry, your lab work becomes more predictable and efficient. You can plan syntheses and analyses without worrying about moisture. You can also reuse the molecular sieve for multiple batches. This balance of cost-effectiveness and performance is why many labs adopt 3Å molecular sieves as their go-to drying strategy.

Conclusion

I depend on 3Å molecular sieves to keep acetonitrile dry and consistent, which makes my work smoother and more reliable.