I see a lot of people overlook the importance of removing moisture from CNG. That leads to equipment headaches, pipeline clogs, and big repair costs.

When CNG is wet, it can form hydrates in cold conditions. Those hydrates can block valves and pipelines, cause corrosion, and damage engines. Drying the gas with 4A molecular sieves solves this problem by taking out the moisture without changing the gas composition.

I learned this the hard way when I was looking for ways to stop hydrates from forming in our lines. I want to share what I discovered and how 4A sieves help.

Why Dry CNG Matters: The Secret to Smooth Rides and Happy Engines?

I often see vehicles struggle when moisture builds up in CNG. That moisture can freeze or form acids that harm engines.

Dry CNG makes engine operation smoother and prolongs the life of compressors and pipelines. Fewer clogs mean better performance in cold weather and fewer downtime incidents.

The Real Risks of Moist CNG

I remember a winter when I was worried about hydrates forming in our pipelines. The outside temperature dropped below freezing, and everything slowed down. Frozen hydrates made it impossible to keep gas flowing. That experience showed me why dryness is not optional. Hydrates can form whenever water vapor is present, especially when the temperature falls around or below 0°C. When raw natural gas has moisture, it invites big problems.

First, hydrates look like ice, but they form faster and cling to surfaces. They can block nozzles and valves. Second, natural gas can have other components, such as hydrogen sulfide and carbon dioxide. When water is present, these gases can combine and form mild acids. Those acids corrode pipes and tanks. The corrosion can damage expensive components. I once spent weeks dealing with pipeline repairs because of that. We had to replace sections of piping and fix leaks that developed from acidic attacks.

Also, wet CNG disrupts compression. When CNG is pressurized and then cooled, moisture in the gas can make ice-like crystals. These crystals stop gas from flowing smoothly. Imagine a busy road with sudden blockades. Nothing moves. That was our situation. We could not dispense fuel properly. Cars lined up at the station, but the system was stuck. Drivers got impatient. Costs went up. Maintenance skyrocketed. The entire operation took a hit.

On top of that, wet gas can affect the engine. Water vapor in the combustion chamber leads to incomplete combustion. That can produce more wear on engine parts. Over time, the engine can accumulate deposits. These deposits shorten engine life and lead to more frequent maintenance. I have seen big fleets face major overheads for engine repair because of water-related damage. That is why dryness is not just a technical detail. It is the key to smooth performance and lower costs.

Below is a simple table that shows the major risks linked to wet CNG and the impact they can have:

| Risk | Consequence | Impact on Operation |

|---|---|---|

| Hydrate Formation | Valve and nozzle blockages | Reduced fuel flow |

| Acid Formation | Pipeline and compressor damage | High repair expenses |

| Engine Wear | Incomplete combustion | Increased maintenance |

| System Downtime | Frozen or blocked lines | Lost revenue and trust |

These problems can be avoided by using the right adsorbent to remove water. Dry CNG matters because it ensures reliable operations. It keeps lines clear and engines happy. It also helps your bottom line by cutting downtime. I will talk next about how 4A molecular sieves solve this moisture challenge.

4A Molecular Sieve: The Tiny Hero Behind Ultra-Dry CNG?

I was impressed the first time I saw how much moisture 4A sieves can pull out. They are tiny but mighty and they are easy to put in the system.

4A molecular sieves act by physically adsorbing water vapor. They do this selectively, so they do not affect the actual natural gas. This means more efficient moisture removal without producing extra pollutants.

Why 4A Sieves Stand Out

I tested other ways to dry gas in the past, like glycol dehydration and other adsorbent materials. Those can be effective, but they sometimes bring complexities, extra chemicals, or additional steps that slow everything down. 4A molecular sieves are simple. They remove moisture through selective adsorption. That means water molecules fit perfectly inside their pores, but larger molecules like methane pass by. This is a neat property because it keeps the main gas composition stable.

I find that 4A sieves do not cause pollution. They work through a physical adsorption process, so they do not alter the chemistry of the gas. When I handled glycol systems, I worried about leaks or disposal. But with 4A molecular sieves, the disposal or regeneration is straightforward. You can heat them or use pressure changes to drive off the adsorbed water. That is an important benefit because you want to preserve the environment and keep your process safe.

Another reason 4A sieves make sense is that they resist acid damage. Wet gas might have carbon dioxide or hydrogen sulfide, which can become acidic in the presence of water. I saw how standard materials degrade under those conditions. 4A sieves do better because they are more resistant to acid or alkali damage. This resilience lets them last longer, which reduces the frequency of replacement. Less replacement means lower operating costs.

I also like the strong compressive strength of 4A molecular sieves. In a high-pressure system, the adsorbent material needs to hold up to mechanical stress. If it breaks down, dust or small fragments can clog the system. That does not help. The robust structure of 4A sieves keeps them intact even when they face repeated pressurization and depressurization cycles.

Here is a short table that highlights why 4A sieves excel:

| Feature | Benefit | Why It Matters |

|---|---|---|

| Selective Adsorption | Removes moisture, not methane | Purity remains high |

| Physical Adsorption | No extra pollutants | Environmentally friendly |

| Acid/Alkali Resistance | Less breakdown under harsh conditions | Longer lifespan |

| High Compressive Strength | Handles pressure swings | Stable and reliable |

I once assisted in a project where we replaced traditional drying methods with 4A molecular sieves. The system needed less downtime, and the gas station did not freeze up when winter came. Drivers were happy, and the company saved money on repairs. That helped me see the direct link between a good adsorbent and profitable operations.

From Gas to Go: How 4A Sieves Keep Your Vehicle Running Like a Dream?

I recall a time when our vehicles kept stalling in freezing conditions. We tracked the issue to wet CNG that caused hydrates in the fuel lines. It was a big nuisance.

Using 4A molecular sieves made a difference. We saw fewer stalls, and the engines stayed cleaner. Drivers noticed improved throttle response, especially in cold weather.

The Practical Roadmap for Dry CNG

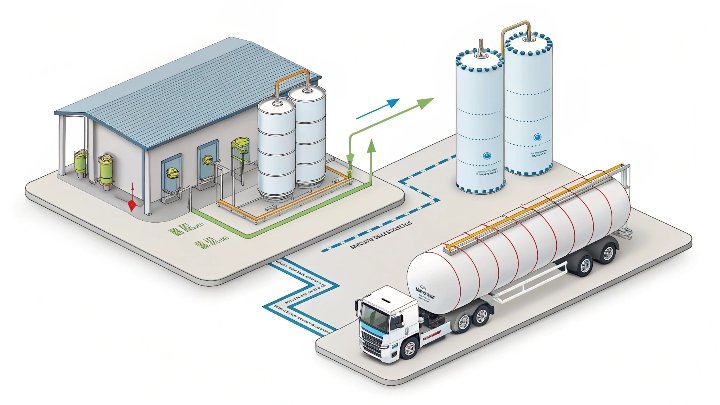

I want to explain how 4A molecular sieves fit into the normal CNG supply chain. Raw biogas or natural gas often arrives with moisture. It might also carry carbon dioxide, hydrogen sulfide, and other things that form corrosive acids when combined with water. That leads to pipeline corrosion, engine deposits, and the dreaded hydrates that can freeze and block lines. To avoid these risks, the gas needs to be dried before compression. This is where 4A sieves do their best work.

The process usually involves passing the feed gas through a vessel packed with 4A molecular sieves. The sieves trap water molecules while letting methane, carbon dioxide, or other gases pass. A well-designed system uses multiple beds. One bed adsorbs moisture while another is being regenerated. Regeneration can happen by heating the spent bed or depressurizing it. The water that was adsorbed is removed from the sieves. After that, the bed is ready for another cycle.

I have also noticed that using 4A sieves for CNG drying offers consistent results. The dew point of the gas can be lowered to a safe level, often well below freezing. That means the gas remains stable, even when winter temperatures plunge. Equipment then remains free of blockages. This is crucial for fueling stations and onboard vehicle systems. Drivers do not want to face fueling problems in subzero temperatures.

Another benefit is that 4A sieves help you reduce maintenance costs. When your fuel is dry, you avoid clogging. You do not need frequent cleaning of nozzles or lines. Your engine and storage tanks also last longer because they do not face corrosive acids. I have seen entire fleets improve their reliability after adopting 4A sieve-based drying systems. The vehicles needed fewer repairs, and the station operations were more predictable.

Below is a summary table that links each step from gas production to vehicle operation and explains how 4A sieves help:

| Step | Potential Problem | 4A Sieve Solution |

|---|---|---|

| Biogas Production | Moisture in raw gas | Adsorbs water to prevent hydrates |

| Compression | Possible ice crystal formation | Removes water before compression |

| Storage and Distribution | Pipe corrosion, blockages | Keeps pipelines clear and safe |

| Vehicle Fueling | Cold starts, nozzle freezing | Delivers dry gas to fueling nozzles |

| Engine Operation | Corrosion and rough combustion | Ensures better engine performance |

I remember one driver telling me that his truck used to sputter in cold months. After we upgraded our drying system with 4A sieves, he did not have a single cold-weather stall. That real-world feedback mattered to me. It showed that a simple change like better moisture removal can solve many practical problems.

Conclusion

I value 4A molecular sieves because they keep CNG dry and protect both vehicles and equipment. They make every ride smoother and more reliable.