Are you tired of unwanted water ruining your process? I felt that frustration too, which drove me to discover the power of 3A molecular sieves.

This technology targets water molecules inside solvents. Its small pore size effectively traps moisture while letting bigger molecules pass. That is why 3A molecular sieves are a top choice for precise solvent dehydration in demanding applications.

I learned that the smallest details can make a big impact when removing water from solvents. This realization changed how I approach drying needs in different industries. Now, I want to share what I discovered about 3A sieves. I hope this helps you see why these sieves matter for anyone who needs dependable, precise solvent dehydration. Let’s explore their pore size, their practical benefits, and how to reuse them effectively.

Small Pores, Big Impact: How 3A Molecular Sieves Trap Water?

Do you want a simple solution for water in your solvents? I once struggled with moisture issues until I learned about these small yet mighty sieves.

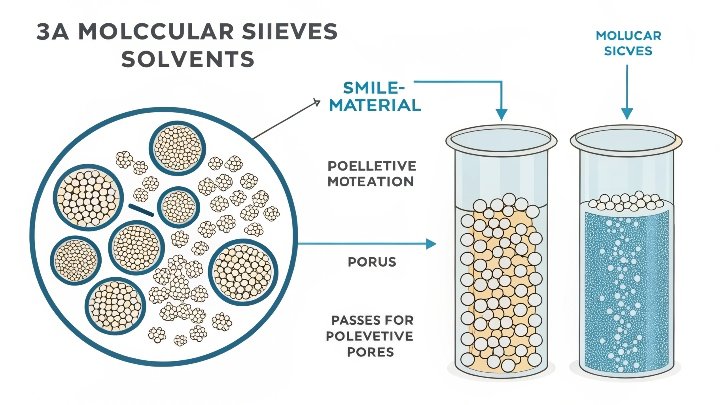

3A molecular sieves have pore openings of about 3 angstroms. They welcome water molecules and keep bigger molecules out. They offer targeted dehydration that stops unwanted reactions and keeps product purity.

These sieves stand out because they focus on water molecules. Their pore size measures around 3 angstroms. That means they capture water but ignore bigger solvent molecules. I find this selectivity essential for applications that need strict dryness, such as high-performance coatings or advanced electronics manufacturing. I have seen how moisture can trigger side reactions or degrade product quality in many settings. From my perspective, 3A sieves are indispensable in pharmaceuticals because they help ensure high-purity solvent production. Even tiny amounts of water can undermine critical reactions in drug manufacturing, so removing that moisture is key.

I recall my first time using 3A sieves in a project that demanded ultra-low water levels. I was amazed by how quickly and effectively they pulled out the last traces of moisture. That was a turning point in my approach to dehydration. I now believe 3A molecular sieves are unmatched for precise and efficient solvent drying in critical industries. They lock onto water molecules and hold them tightly, which helps maintain a stable environment for sensitive reactions.

I also appreciate how these sieves reduce extra processing steps. Once they remove the water, I can skip additional drying measures that might be expensive or time-consuming. This saves time and protects my bottom line. I think that is why so many industry professionals, including those in petrochemical and industrial processes, rely on 3A sieves. Their small yet powerful pore size is a game-changer for anyone who needs consistent and repeatable dryness.

| Key Benefit | Description |

|---|---|

| Precise Pore Size | Targets water molecules for efficient drying |

| Protects Purity | Prevents unwanted side reactions in sensitive processes |

| Saves Resources | Lowers extra drying steps and boosts production economy |

The Solvent Dehydration Hero: Where 3A Molecular Sieves Shine?

Are you looking for a steady workhorse in solvent drying? I know that 3A sieves excel in places that demand accurate and consistent moisture control.

I see them as the hero for chemical and pharmaceutical processes. They guard high-value products from water-induced spoilage and contamination. This means safer, purer outcomes and fewer reprocessing steps.

I have observed these sieves at work in pharmaceuticals, petrochemicals, and other industrial processes. They shine in places where even trace water can trigger big problems. I recall a time when a tiny amount of moisture nearly ruined a specialty chemical batch. By switching to 3A sieves, I saw an immediate drop in water content, which helped restore the product’s stability. This experience showed me that reliable dehydration is crucial for preserving product quality.

I also consider large-scale plants that handle big volumes of solvents. I believe 3A sieves are perfect for these environments because they are durable and do not degrade quickly. They handle repeated cycling, and they can be regenerated, which lowers operating costs. Regenerability stands out to me as a sustainable and cost-saving measure. With proper regeneration techniques, these sieves can work through many cycles before replacement becomes necessary. That prevents downtime and helps me control expenses.

Their small pore size also prevents valuable solvents from being adsorbed. If I used a sieve with pores that were too large or too open, I could lose some of the solvent, which would affect my efficiency. With 3A sieves, I can maintain purity while taking out water. Their selectivity is important for high-value processes, especially in industries that need to minimize waste and maintain consistent yields. Each time I face a strict drying requirement, I see 3A sieves as my go-to solution because they deliver stable outcomes, protect my products, and keep my process on track.

| Application | Benefit |

|---|---|

| Pharmaceuticals | Maintains strict purity standards |

| Petrochemicals | Protects product stability and performance |

| Industrial | Lowers downtime through easy regeneration |

Regeneration Hacks: Reviving 3A Molecular Sieves for Reuse?

Do you want to save costs and go greener at the same time? I found that properly regenerating 3A sieves can unlock more value from each batch.

Regeneration is the process of driving off adsorbed water. I do this through heat or reduced pressure. This lets 3A sieves return to optimal performance, lowering replacement expenses.

I like how 3A molecular sieves can be used again after a proper regeneration cycle. This process usually involves heating them to a temperature that forces out the trapped water. Sometimes, I pair this step with reduced pressure or a stream of dry purge gas. This combination helps remove stubborn moisture that might otherwise remain in the pores. By reactivating the sieves, I extend their lifespan and reduce the cost of buying fresh materials, which is good for my budget and the environment.

I see a sustainable advantage when I reduce the amount of spent adsorbent going to waste. Many industries emphasize green initiatives, so the ability to reuse sieves is a plus. I have seen big facilities implement onsite regeneration systems that lower downtime and shipping expenses. This allows production to continue with minimal disruptions. I also think it is critical to control the heating parameters during regeneration. If I overheat the sieves, I can damage the pore structure. If I do not heat them enough, I can leave water in the pores. So I always pay close attention to recommended temperature ranges and best practices.

I consider 3A sieves a smart investment because their regenerability makes them a durable tool. Each time I prepare for a new drying cycle, I know I can restore their high efficiency without significant hassle. This helps me focus on producing consistent, moisture-free solvents. Whenever I aim to cut costs and stay eco-friendly, I turn to 3A molecular sieves. They give me reliable drying and a way to keep reusing the same adsorbent for many cycles.

| Regeneration Method | Key Steps |

|---|---|

| Thermal | Heat to remove adsorbed water |

| Vacuum | Use low pressure to pull out moisture |

| Purge Gas | Pass inert gas to aid water removal |

Conclusion

I see 3A molecular sieves as the clear choice for precise and efficient solvent dehydration. Their small pore size, reliability, and easy regeneration make them a trusted ally.