I faced confusion when I first heard about molecular sieves. They sounded complex. But I realized they solve major adsorption challenges with ease. They help many industries.

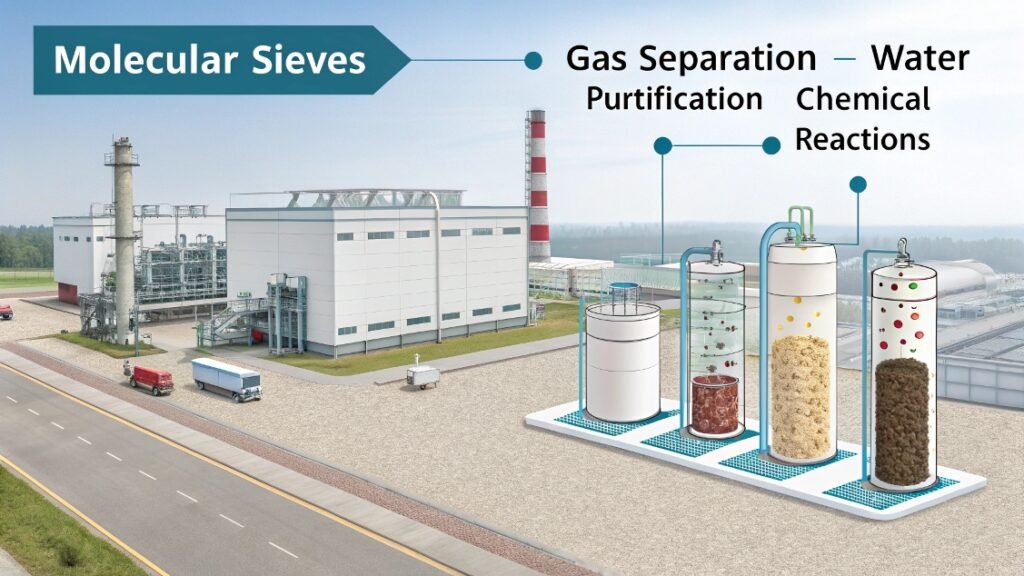

Molecular sieves are solid adsorbents that remove targeted molecules from gases or liquids. They have uniform pore sizes. They are used in gas drying, purification, and chemical processes.

I want to share why molecular sieves matter. They help me achieve high efficiency in separation tasks. They also save costs because they last a long time and can be regenerated. I recall how I struggled to remove moisture from a gas stream using other methods. Molecular sieves solved this problem. They also handle a wide range of temperatures and pressures. That is one reason I trust them.

What are the applications of molecular sieve?

When I started working with molecular sieves, I discovered their vast applications. They are used in drying, purification, and even in pharmaceuticals.

Molecular sieves help industries remove water, impurities, and specific chemical compounds. They also protect sensitive processes from contamination. This is why they are crucial in gas refining and industrial manufacturing.

I want to dive deeper into their many applications. Let me break it down:

Gas Drying and Purification

One of the first things I learned is that molecular sieves excel at gas drying. They remove moisture from natural gas, compressed air, and other gas streams. This prevents corrosion and damage to equipment. I recall a time when a colleague asked me why typical drying methods were not enough for their pipeline. I explained that molecular sieves are more efficient because their uniform pores trap water molecules very well. This ensures minimal residual moisture. It also avoids complications like freezing and pipeline blockages.

Additionally, I found that molecular sieves target specific contaminants. For instance, they remove carbon dioxide, hydrogen sulfide, or other impurities from gas streams. This enhances product quality and reduces environmental impact. I appreciate their ability to maintain consistent performance over many cycles. I simply regenerate them through heating or pressure changes.

Environmental Protection

I see molecular sieves used in pollution control. They can adsorb and remove harmful compounds from industrial emissions. This helps me meet environmental regulations. It also ensures that I play my part in reducing pollution. Their stability under different conditions means they can operate for long periods without major performance drops.

Pharmaceutical and Medical Uses

I also discovered that molecular sieves help in pharmaceutical production. They maintain strict purity levels in drug manufacturing. They remove unwanted water or solvents, which keeps the final product stable. This boosts safety and efficacy. Some medical devices also rely on molecular sieves for controlled adsorption processes, like oxygen concentrators.

Table: Overview of Key Applications

| Application | Purpose | Benefits |

|---|---|---|

| Gas Drying | Removes water vapor | Prevents pipeline issues |

| Gas Purification | Eliminates contaminants | Ensures cleaner product |

| Pharmaceuticals | Controls moisture | Preserves drug stability |

| Environmental Control | Adsorbs harmful compounds | Reduces emissions |

| Medical Devices | Provides precise adsorption functions | Enhances safety and efficiency |

Each of these applications shows me that molecular sieves are versatile and robust. I trust them to handle challenges that ordinary adsorbents cannot. Their high selectivity is key. I rely on them for tasks like moisture control, odor removal, or even advanced separations. I enjoy how I can adapt them to different flow rates, pressures, or temperatures. This range of applications makes molecular sieves essential in many industries.

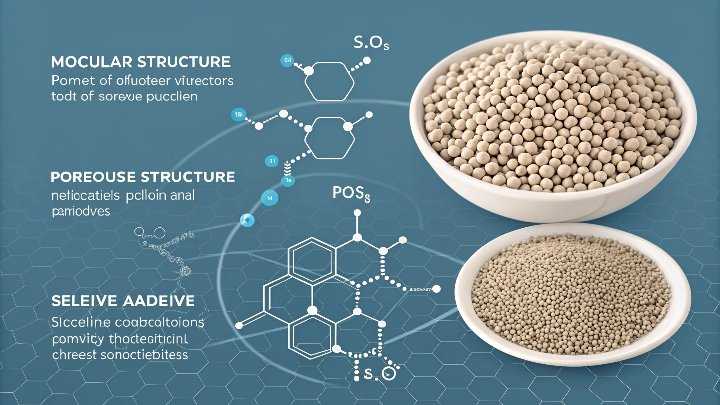

What are the characteristics of molecular sieve?

I used to think all adsorbents were similar. But molecular sieves proved me wrong. Their uniform pore structure is impressive. Their durability is even more so.

Molecular sieves have well-defined pore sizes, strong adsorptive power, and long operational life. These features help me achieve consistent performance under demanding conditions.

Let me share more about their important characteristics:

Pore Structure and Selectivity

Molecular sieves are made from crystalline aluminosilicates. Their pore sizes are uniform, usually measured in angstroms. This precise structure gives them the ability to selectively adsorb molecules based on size and polarity. I remember a colleague asking me how to remove only water but leave larger hydrocarbons untouched. I recommended a 4A molecular sieve. Its pore size is around 4 angstroms, which is ideal for water. Larger molecules cannot fit, so they remain in the stream. This precise molecular discrimination helps me design targeted processes.

Regenerability and Lifespan

I appreciate that molecular sieves are easy to regenerate. When they become saturated, I can apply heat or a vacuum. This drives out the adsorbed molecules and restores the sieve’s capacity. This cycle can happen many times without losing efficiency. This means lower costs over time. I find that this feature is especially helpful in large-scale systems. Instead of frequently replacing adsorbent, I can keep using the same batch for a long time. This reduces waste and improves sustainability.

Thermal and Chemical Stability

Molecular sieves can handle high temperatures. They are also chemically stable. This means they do not degrade easily in harsh environments. I have used them in conditions where other adsorbents fail due to heat or chemical exposure. Molecular sieves keep working, which saves me from unscheduled downtime. Their chemical stability also ensures they do not react with sensitive products. That is essential in food processing or pharmaceutical applications.

High Adsorption Capacity

I often highlight the high adsorption capacity of molecular sieves. They can trap a large amount of water, carbon dioxide, or other molecules. This is important in processes that require dryness or purity. With a single pass through a properly sized bed, I achieve the desired results. This high capacity also means smaller equipment footprints, which can reduce capital costs. It is one reason I always promote the use of molecular sieves in new designs.

Table: Major Characteristics of Molecular Sieves

| Characteristic | Description | Benefit |

|---|---|---|

| Uniform Pore Structure | Crystalline framework with fixed pore size | Selective adsorption of specific molecules |

| Regenerability | Can be heated or purged to remove adsorbed substances | Extended lifespan, lower replacement costs |

| Thermal Stability | Maintains structure at high temperatures | Reliable performance in harsh conditions |

| Chemical Stability | Resistant to most chemicals | Suitable for diverse applications |

| High Adsorption Capacity | Adsorbs large amounts of target molecules | Efficient removal of contaminants |

In my experience, these characteristics make molecular sieves indispensable. They handle challenging separations and keep performance levels stable. That reliability saves me time and money.

How do Molecular Sieves work?

I often get asked about how molecular sieves actually function. The concept is simple yet powerful. Their pores act like tiny sieves that let certain molecules in while blocking others.

Molecular sieves rely on size exclusion and polarity to adsorb targeted molecules. Heating or purging them removes these molecules, restoring capacity for repeated use.

Let me explain the mechanism further:

Size Exclusion Principle

The first step is understanding that each molecular sieve has a specific pore size. When a gas or liquid mixture contacts the sieve, only molecules small enough to fit in the pores are adsorbed. I often compare it to sorting small stones from bigger rocks by passing them through a mesh. The smaller pieces get captured inside, while the bigger ones remain outside. This is the essence of how molecular sieves separate molecules by size.

Polarity and Attraction

Molecular sieves also rely on polarity differences. Water molecules are highly polar, so they are strongly attracted to the charged sites in the aluminosilicate framework. That is why molecular sieves are so effective at water removal. In my own work, I have seen how a 4A molecular sieve attracts water more strongly than other adsorbents, even if some other molecules could fit in the pores. This polarity effect increases the efficiency of the sieve.

Regeneration and Reusability

Once the sieve is saturated, I restore its function by heating or purging it with dry gas. This step drives off the adsorbed molecules, leaving the pores open. This cycle of adsorption and regeneration can happen many times. I once showed a coworker how to set up a two-tower system. One tower adsorbs contaminants while the other regenerates. This approach ensures continuous operation without downtime. The key is monitoring temperature and flow rates to ensure complete regeneration.

Practical Considerations

I always keep a few factors in mind when using molecular sieves. First, the bed design is critical. Proper contact time ensures maximum adsorption. Second, I choose the correct pore size for the task. A mismatch can lower efficiency. Third, I consider how to dispose of the purged molecules safely to protect the environment. Finally, I track pressure drop across the bed. If it increases, the bed might be fouled or clogged, which reduces performance.

Table: How Molecular Sieves Work

| Step | Process | Result |

|---|---|---|

| Adsorption | Selective uptake of small or polar molecules | Removal of target contaminants |

| Saturation | Pores fill up with adsorbed molecules | Adsorption capacity reaches limit |

| Regeneration | Heat or purge gas to remove trapped molecules | Restored pore space for reuse |

| Continuous Operation | Use multiple beds or towers in parallel | Minimizes downtime and increases efficiency |

Understanding this cycle helps me optimize operations. I appreciate how molecular sieves can be reused multiple times. This reduces waste. It also makes the system more cost-effective over the long term. I find molecular sieves to be reliable allies in achieving consistent purity levels in many processes.

Conclusion

Molecular sieves help me handle challenging adsorption and separation tasks. They are precise, durable, and versatile, which makes them vital in many industries.