Natural gas reforming is crucial for hydrogen production, but its traditional methods come with hidden costs that can be avoided. Read on to discover how molecular sieves can save you millions.

Natural gas reforming plays a key role in producing hydrogen for industries like energy and chemicals, but hidden costs like catalyst damage, energy wastage, and impurities add up. Sieves can save you millions.

To fully grasp how molecular sieves save money, let’s break down the hidden costs in the reforming process. These issues, although often overlooked, can significantly impact both efficiency and the bottom line.

The Catalyst Killer Your Supplier Won’t Tell You About: H2S Damage at 320°C

Hydrogen sulfide (H2S) is a silent killer in natural gas reforming. At temperatures around 320°C, it reacts with your catalysts, causing them to deteriorate quickly. This leads to increased operational costs and downtime.

H2S is a common impurity in natural gas, but many suppliers don’t highlight its dangers to your catalysts. When it reacts at high temperatures, it causes irreversible damage, increasing the need for costly replacements.

H2S Damage Explained

Hydrogen sulfide (H2S) is a common contaminant in raw natural gas, and it can wreak havoc on catalysts in reformers. The reforming process relies on catalysts, which speed up reactions needed to convert methane into hydrogen. However, when H2S is present in the gas stream, it poisons these catalysts, reducing their effectiveness and lifespan.

At high temperatures, like 320°C, H2S reacts with metals in the catalyst, causing them to corrode or become deactivated. This leads to costly catalyst replacements and increased maintenance downtime. Suppliers often overlook the role of H2S in catalyst deterioration, but if left unaddressed, it can add substantial costs to the operation.

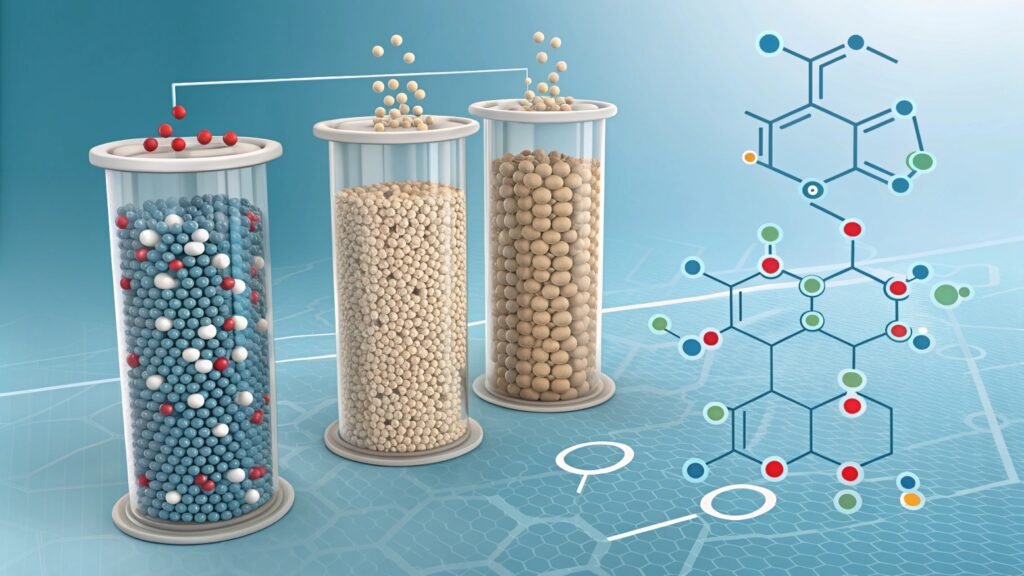

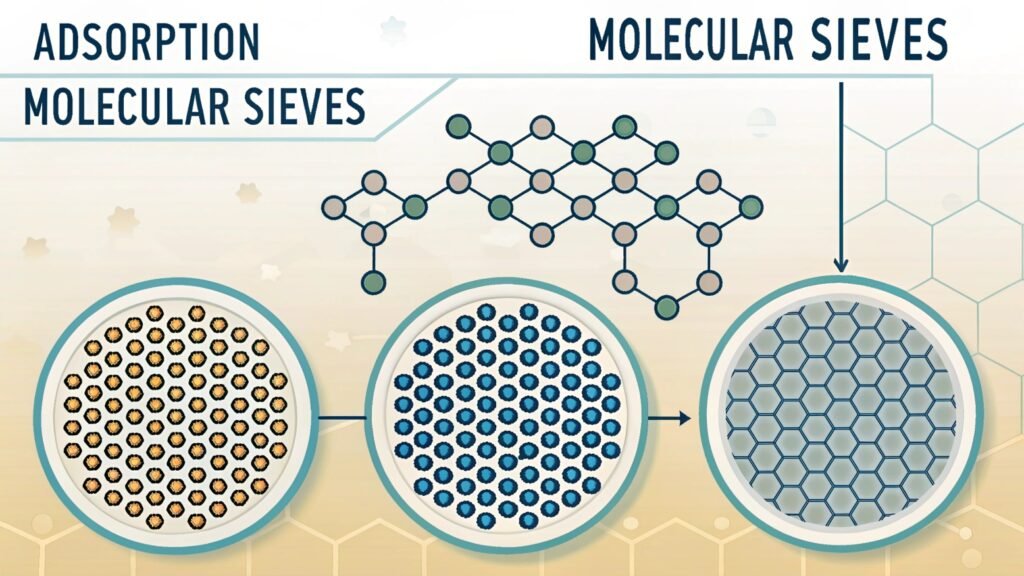

To combat this, removing H2S during the raw gas pretreatment stage is essential. Molecular sieves (like 5A) can adsorb H2S efficiently, preventing it from reaching the catalyst beds. By incorporating sieves into your pretreatment, you ensure a cleaner gas stream and protect your valuable catalysts from unnecessary damage.

Steam Reformers’ Dirty Secret: How 38% Energy Wastage Occurs in Pre-treatment

Energy wastage in the pretreatment phase of steam methane reforming (SMR) is more common than you think. The process of drying the gas stream before reforming requires significant energy, often wasting up to 38% of the total energy input.

Pretreatment can waste a lot of energy if not managed well. In the case of SMR, drying the raw gas accounts for nearly 40% of the total energy consumed.

The Energy Drain of Pretreatment

The pretreatment stage in natural gas reforming involves the removal of moisture and impurities from the raw gas. While this is necessary for a smooth reforming reaction, it’s often a highly energy-intensive process. The drying phase, in particular, requires heating the gas to remove moisture, consuming a large amount of energy. On average, around 38% of the total energy used in SMR goes into this phase.

Traditional drying methods, such as using activated alumina or silica gel, may not be the most efficient when dealing with high moisture content. They require substantial energy input to operate at the temperatures needed to remove moisture effectively.

This is where molecular sieves shine. Sieves, especially types 5A and 13X, have a high moisture adsorption capacity, ensuring a dry methane feed while minimizing energy consumption. Unlike traditional methods, sieves operate more efficiently, reducing the energy required for drying. By integrating molecular sieves into your pretreatment system, you can cut down on energy wastage and significantly improve the overall energy efficiency of the reforming process.

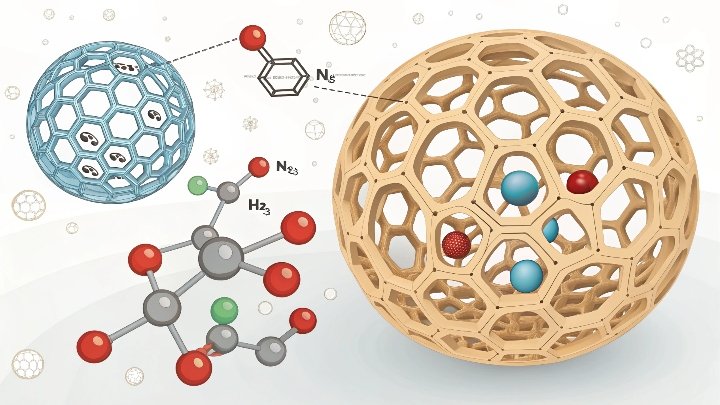

Shale Gas Revolution: How X-Type Sieves Enable 90% Purity at Half Pressure

Shale gas is revolutionizing the natural gas industry, but it comes with its own set of challenges. One of the biggest hurdles is achieving high hydrogen purity under lower pressures. Traditional methods require high-pressure systems to reach acceptable purity levels. This can be costly and inefficient. Enter X-type sieves.

X-type molecular sieves enable hydrogen purity of up to 90% at half the pressure, making them a game-changer for shale gas operations.

Achieving High Purity with Low Pressure

Shale gas presents a unique challenge in natural gas reforming. Unlike conventional natural gas, shale gas often contains higher levels of impurities, making purification more difficult. Traditional methods typically require high-pressure systems to achieve hydrogen purity levels above 90%. This means more energy consumption and higher operational costs.

X-type molecular sieves, however, are capable of achieving 90% purity at much lower pressures. This ability is crucial for industries that operate in shale gas fields, where reducing pressure can lead to significant savings in energy and operational costs. X-type sieves work by selectively adsorbing impurities, such as carbon dioxide and nitrogen, from the gas stream. They do this with minimal energy input, allowing you to achieve high purity while keeping pressure requirements low.

By using X-type sieves, shale gas operations can reduce energy consumption, lower operating pressures, and still achieve the same level of purity as traditional high-pressure methods. This innovation is a crucial step toward making shale gas a more viable and cost-effective source of hydrogen.

Conclusion

Natural gas reforming may be the key to sustainable hydrogen production, but traditional methods come with hidden costs. By using molecular sieves, you can save millions in energy, catalyst replacements, and operational efficiency.