MOLECULAR SIEVE

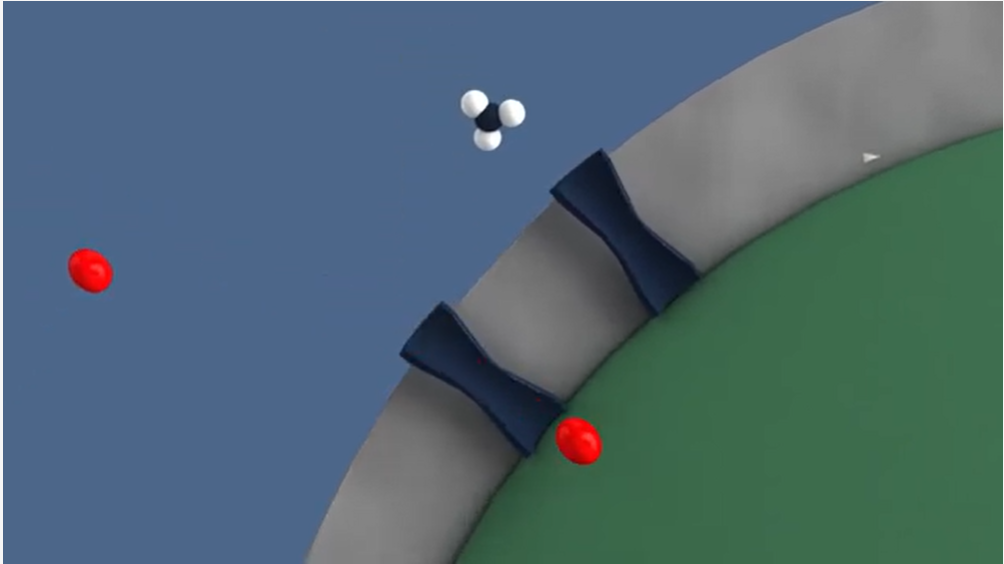

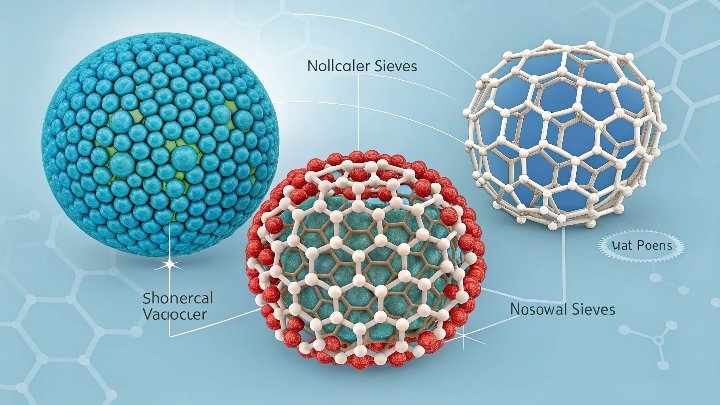

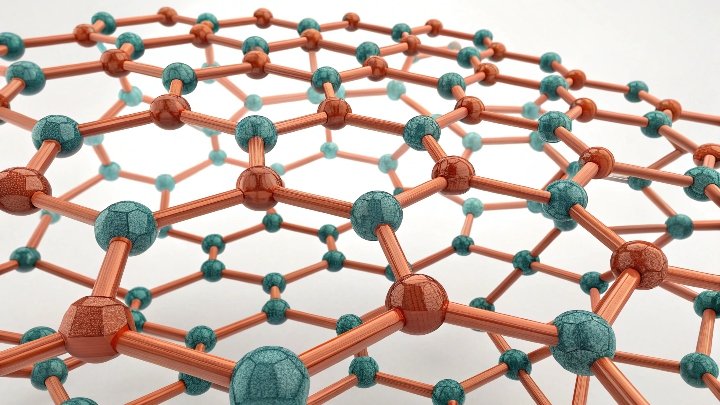

Zeolite molecular sieves have the structure and characteristics of crystals, the surface is a solid skeleton, and the internal holes have the function of adsorbing molecules. There are pores connected, and molecules pass through the pore’s channels. Due to the crystalline nature of the pores, the pore size distribution of molecular sieves is very uniform. Molecular sieves according to the size of the holes in their crystal selectively adsorb molecules, that is, they adsorb molecules of a certain size and repel molecules of large substances, so they are figuratively called “molecular sieves.”

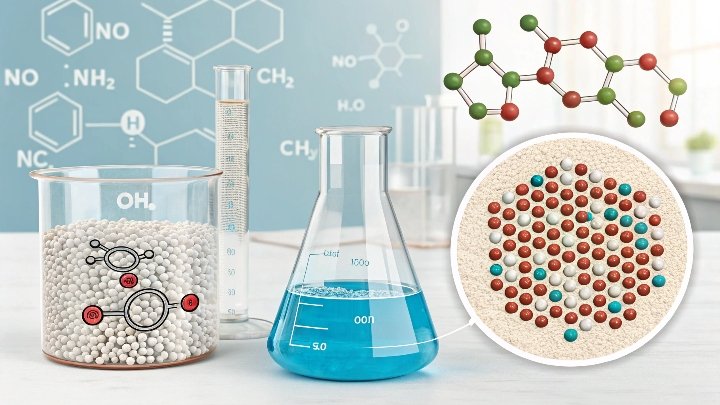

The function of molecular sieve adsorption or repulsion is affected by the polarity of the molecule. Synthetic zeolite has the special function of selective adsorption according to the size and polarity of the molecule so that gases or liquids can be dried or purified, which is the basis for the separation of molecular sieves. Synthetic zeolite can meet the extensive needs of the industry for adsorption and selection of characteristic products, and it is also widely used in industrial separation.

Table Of Contents For This Page

It is not easy to introduce all aspects of our products, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

What We Are Manufacturing

We provide Products not only competitive price but also good quality!

General Hot Selling Products

Here are some hot selling products, their core parameters and unique selling points, if you want catalog with more details, contact us from now on!

Wanna dig deeper in cooperation?

Our Molecular sieve Used For Below industries

CNM has been serving various market sectors where Molecular sieve play an integral role. These industries demand high-quality Molecular sieve.

- Natural gas processing

- Basic petrochemical and syngas processes

- Petroleum refining

- Production of ethanol fuel

- Hydrogen production and recycling

- Industrial Gases

- Chemical storage

- Packaging protection

- Pollution and VOC Control

- Medical use

- Refrigeration and air conditioning systems

- Air dryer

- Polymer processing

What is a molecular sieve used for?

Molecular sieves are used for drying gases and liquids and for separating molecules on the basis of their sizes and shapes.

When two molecules are equally small and can enter the pores, separation is based on the polarity (charge separation) of the molecule, the more polar molecule being preferentially adsorbed.

What is molecular sieving?

Molecular sieves are materials with pore sizes of molecular dimensions within which, ignoring surface effects, selectivity is a function of molecular size, with smaller molecular species having higher diffusion rates.

In molecular sieve studies, permeate molecules are commonly known as “guest” molecules.

Are molecular sieves toxic?

However molecular sieve is not toxic. Molecular sieve is hygroscopic which means that when accidentally beeing consumed/swallowed the product will attract moisture from the surroundings i.e. the gastrointestinal (GI) tract. Molecular sieves are not considered to be persistent, bioaccumulating nor toxic (PBT).

How do molecular sieves remove water?

Molecular sieves are in the family of desiccants, also known as adsorbents, used for hydrocarbon drying, described as the removal of dissolved water from hydrocarbon gases and liquids. Refineries use molecular sieves dryers for many dissolved water removal applications.

What are the disadvantages of molecular sieves?

Costs – molecular sieves are often more expensive than other techniques in the purchase price.

Fragile – molecular sieves can break which can result in particles that can get into a process.

Selective – not always applicable after removal of various molecules.

How many times can molecular sieves be reused?

Once regenerated, allow material to cool for at least an hour before handing or placing in storage.

You can reuse molecular sieve multiple times as long as proper regeneration steps are followed. Repeat when necessary!

How do I choose a molecular sieve?

The selectivity of a molecular sieve is determined by its pore size, molecules with a critical diameter which is less than the pore size will be efficiently adsorbed while larger molecules will be excluded.

How do you test a molecular sieve?

- pour an amount (volume) of water in glass (e.g. 10 ml).

- place thermometer in it and record the temperature.

- The same amount or few more (pour in cylinder to 12 ml of molecular sieve).

- pour it on the water glass.

- Observe the increase in temperature of the mixture.

- Record the highest degree of temperature.

- If the difference is more than 10°C, the molecular sieve is in satisfactory condition.

How to choose molecular sieves?

To choose a molecular sieve, consider the specific application, the type of molecules to be separated, the desired purity level, and the operating conditions.

Different molecular sieve types have varying pore sizes and adsorption properties, so selecting the appropriate type is crucial for optimal performance.

TOP 5 Molecular Sieve Manufacturers

Here are the top 5 molecular sieve manufacturers globally:

Honeywell UOP (Universal Oil Products)

- Location: USA

- Specialization: Honeywell UOP is a leading provider of molecular sieves and adsorbents, focusing on the petrochemical, refining, and gas processing industries. They are well-known for their high-quality 3A, 4A, 5A, and 13X molecular sieves.

Zeochem AG

- Location: Switzerland

- Specialization: Zeochem produces high-performance molecular sieves used in a variety of applications, including industrial gas production, medical oxygen generation, and ethanol dehydration.

Arkema (CECA)

- Location: France

- Specialization: CECA, a subsidiary of Arkema, is a prominent player in the molecular sieve market, offering a wide range of sieves for gas drying, purification, and separation processes.

Tosoh Corporation

- Location: Japan

- Specialization: Tosoh is known for its advanced technology in the production of molecular sieves, particularly in the fields of petrochemical and gas processing industries. Their products include a variety of sieve types tailored for specific industrial applications.

Grace Catalysts Technologies (W. R. Grace & Co.)

- Location: USA

- Specialization: Grace Catalysts Technologies offers a wide range of molecular sieves, focusing on applications in refining, petrochemical processing, and gas separation. Their products are renowned for their reliability and performance.

These companies are recognized for their innovation, quality control, and global distribution networks, making them leaders in the molecular sieve industry.

The FAQs About CNM

There are some questions and answers here to help you quickly know our serivice.

What is your MOQ?

Our MOQ is 500 kilograms, which varies with different products.

What about your delivery time?

5-15MT, 3-5 days//15-25MT, 5-7days//25MT-xxxMT, 7-10days. Our delivery time will be adjusted according to your demand.

Do you have export experience?

Our export sales team have exportting business more than 20 years. You will happy for our profressional working way.

If your products have quality control?

Yes, we manufacture according to ISO9001 system. Have a full quality control in the whole process.

Sample free or need to pay?

If you are our new cusotmer, you are expect to pay the sample and freight for sample delivery. When you place formal batch order more than 20,000 USD after sample testing, We will consider deduct part of sample fee from the tota amount of formal batch order. But this will discuss by both of us, because not sure your sample qty and total amount.

What is your terms of payment

- Payment less than 8000USD, 100% in advance. Payment more than 8000USD, 30% T/T in advance ,balance before shipment.

- If you have another question, please feel free to contact us.

Shipping

a. For small trial order, by air or by express :FEDEX, DHL, UPS, TNT etc

b. For large order, we arrange shipment by sea or by air according to your requirement.

How can you guarantee quality?

Always a pre-testing material before mass production;Always final Inspection before shipment.