PSA Molecular Sieve

PSA Special molecular sieve for Oxygen enrichment is a kind of synthetic aluminosilicate crystals. According to its different silicon-aluminum ratio, different types of molecular sieves can be generated. This molecular sieve can be ion exchanged with different metal cations to become the same type but different classification of molecular sieves. This kind of molecular sieve has a huge specific surface area, a uniform mesh porous structure and a very high degree of deep drying and separation; it can effectively avoid the phenomenon of co-adsorption during separation and improve product yield; this kind of molecular sieve can also complete the drying and purification of substances in the same system at the same time; under higher temperature conditions, it still has a high adsorption capacity; and this kind of molecular sieve can be regenerated andreused, reducing the operating cost.

HOT SELLING Molecular Sieve

Molecular Sieve PSA Application

- PSA oxygen production device

- Oxygen and nitrogen separation

- Production of industrial oxygen

- Medical oxygen enrichment

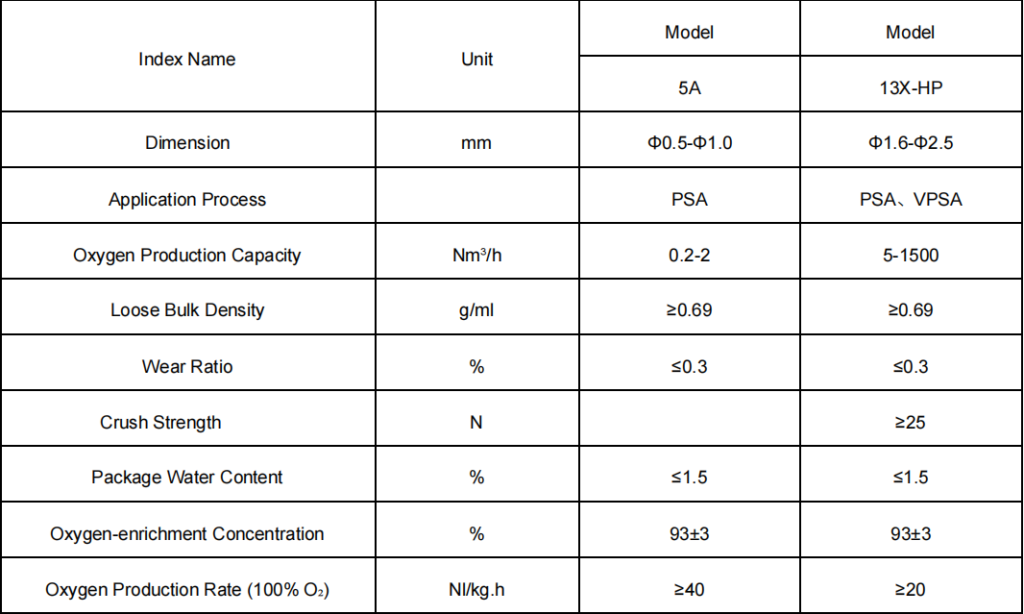

Molecular Sieve PSA Technical Specification

Molecular Sieve PSA Packing

- PE Carton 25/50kg

- Ton/half ton bag package

- Iron drum, net weight 125/135/140kgs

- Customized package by customer requirements

Molecular Sieve PSA Storage

- Room temperature; indoor humidity not more than 90%

- Avoid water, acid and alkali; isolate air and sealed preservation.

Molecular Sieve PSA Regeneration

Chemequip molecular sieve can be purged and regenerated by increasing the temperature, regeneration (dehydration) degree depends on the humidity and temperature of the purging gas.

Water Removal: Heat dry gas such as nitrogen, air, hydrogen, saturated hydrogen carbide to 150-320℃, then pass it into the molecular sieve bed under the pressure of 0.3-0.5 kgf/m2 for 3-4 hours, and then pass the dry cold gas into the adsorber for 2-3 hours, isolate the air and cool it to room temperature.

Organic Removal: Replace the adsorbent from the molecular sieve by vapor and then heat or pass into hot vapor or inert gas at the in 200-350℃, not use gases that produce explosive mixtures by contact with theadsorbent.

Gas Removal: Reduce the pressure.