I notice many industries struggle with moisture or unwanted impurities. I want to ease that frustration. So I wrote this post to show how molecular sieves solve these problems in a direct way.

Molecular sieves look like tiny sponges with specialized pores. They adsorb smaller molecules based on size, while letting bigger molecules pass. This allows them to dry gases, remove impurities, and purify products in many fields.

I believe you will see why molecular sieves are essential. I want to share the structure, the principles, and some hacks to boost efficiency in various industries.

What Makes Molecular Sieves the "Super Sponge" of the Chemical World?

I often hear questions about how something so small can solve big purification problems. I can relate to that confusion. Let me explain the special structure behind their powerful adsorption capacity.

They act like a strict bouncer at a club. Small molecules get in. Big ones stay out. This helps industries separate and purify different gases and liquids with high precision.

Exploring Zeolites, Pore Sizes, and Unique Frameworks

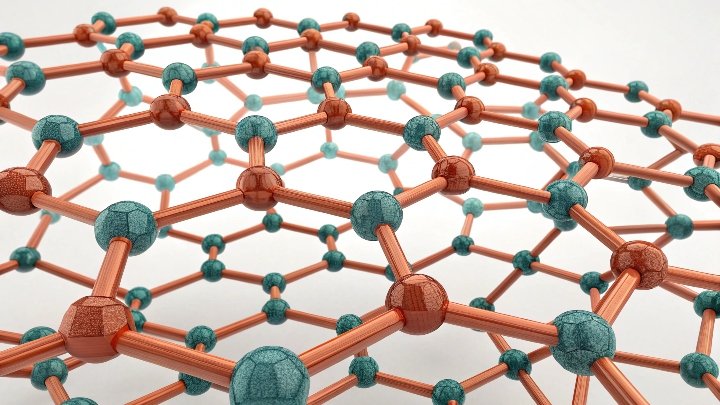

Molecular sieves have a global market value that exceeded US$ 5.1 billion in 2020, and analysts expect it to surpass US$ 6.8 billion by 2026. I see why companies across petrochemicals, pharmaceuticals, and food sectors place so much trust in them. Most commercial molecular sieves come from synthetic zeolites, which have an intricate web of channels made of aluminum, silicon, and oxygen. These channels look like uniform tunnels. This uniformity leads to pores of specific sizes that can adsorb molecules of certain diameters.

Molecular sieves are not just about the raw material; they are also about the size of the pores. For example, Type 3A has pores of about 3 angstroms, which is ideal for trapping water molecules, because water is small and polar. Type 4A, with pores of about 4 angstroms, is widely used in natural gas dehydration and other gas purification processes. Type 5A, at around 5 angstroms, targets normal paraffins and helps separate them from branched or cyclic compounds. Then there is 13X, which has pores reaching about 10 angstroms. This larger pore size can trap bigger molecules such as CO₂ or sulfur compounds.

Carbon molecular sieves also exist. They can come from coal or coconut shells, or even polymer precursors. Their pore distribution is less uniform, but they can separate oxygen and nitrogen or trap volatile organic compounds. Their random structure makes them suitable for some niche processes, like selective adsorption of specific gases in PSA (Pressure Swing Adsorption) systems.

In my experience, pore size is the most important property. I look at the molecules I need to remove and match them to the right sieve size. Water, CO₂, and various hydrocarbons have different sizes, so I pick the sieve with the best pore diameter. Polar molecules like water or alcohols cling tightly to many zeolite frameworks, so 3A or 4A often work for moisture control. Non-polar molecules, such as certain hydrocarbons, respond better to carbon molecular sieves. This simple matching approach is a cost-effective method to get the best results.

| Sieve Type | Pore Size (Å) | Typical Use |

|---|---|---|

| 3A | 3 | Drying polar liquids and gases (e.g., water) |

| 4A | 4 | Dehydration of natural gas, removal of CO₂ |

| 5A | 5 | Separation of normal paraffins from branched ones |

| 13X | ~10 | Adsorption of larger molecules, like CO₂ or H₂S |

| CMS | Varies | Nitrogen/Oxygen separation, VOC adsorption |

I compare these to regular sponges. Molecular sieves have consistent, tiny pores that only let specific molecules in. Because of that, they can produce high-purity outputs, reduce contamination, and help meet stringent pipeline or product requirements. With so many variants, each industry can find a tailor-made solution. That is what makes them “super sponges.”

The Science Behind the Magic: How Molecular Sieves Work?

I know it is easy to assume that these materials only sponge up molecules at random. I understand that confusion. I will show how their selective adsorption actually works step by step.

Molecular sieves trap molecules through physisorption. This means weak forces hold the molecules inside the pore, allowing quick capture or release when conditions change. No major chemical bonding happens.

Adsorption Mechanism, Factors, and Regeneration

At their core, molecular sieves use a size-based gateway. Gas or liquid streams pass through, and any molecule smaller than the pore gets inside. Larger molecules stay outside. This is why we can target specific impurities like water or CO₂ while letting bigger molecules remain free. Because of this, molecular sieves are go-to materials for drying processes or removing certain contaminants.

Temperature and pressure affect their performance. If I raise the temperature too much, the sieves tend to release molecules. This is helpful when I want to regenerate the sieve. If I lower the temperature, adsorption usually increases. Pressure also matters. At higher pressure, more molecules are forced into the pores. This can speed up the adsorption rate. If the feed stream has a high concentration of the target molecule, the sieve will fill faster, though it might also saturate faster.

In many industries, we reuse molecular sieves by applying heat or reducing pressure. That is how we remove the trapped molecules. Thermal regeneration often involves heating the sieve bed to a few hundred degrees Celsius. This vaporizes or drives out the adsorbed molecules. With pressure swing adsorption, we cycle between high and low pressures to push and pull molecules in and out. This means we can keep using the same batch of sieves for a longer time, which lowers overall costs.

I also watch for contaminants that can clog or poison the pores. Some large or reactive molecules might bind strongly. This can reduce capacity over time. I sometimes run pre-treatment steps on the feed, or use multiple beds with different properties to remove complex impurities in stages. When I see performance drop, I check if the bed needs deeper cleaning or replacement. This approach ensures the best results over the long haul.

Because molecular sieves work in a precise way, they outperform many other desiccants in certain tasks. Silica gel can hold water, but it cannot match the deeper dew points reached by molecular sieves. Activated alumina is useful for removing more than just water, but it sometimes lacks the tight molecular size selection. Molecular sieves stand out for pinpoint separation. That is the magic behind how they work, and it is why I rely on them for critical processes.

Real-World Hacks: How Industries Use Molecular Sieves to Boost Efficiency?

I notice that many people wonder if these sieves really make a difference in actual production lines. I get that skepticism. But real-world data shows the importance of these materials.

They are used in petrochemicals, pharmaceuticals, and even food processing. They help remove moisture and impurities to extend product life or improve purity.

Petrochemicals, Food, and Pharma Applications

One major use of molecular sieves is gas purification in the petrochemical industry. Natural gas has water vapor, carbon dioxide, and other contaminants. These can corrode pipelines or cause hydrates to form. I see 4A sieves removing water and CO₂ so that the gas meets pipeline standards. They help maintain dryness, reduce corrosion, and improve heating value.

Many refineries also produce high-purity hydrogen for hydrotreating or hydrocracking. Pressure swing adsorption units often use molecular sieves to remove leftover CO₂, H₂S, or other small molecules. The result is hydrogen with purity up to 99.9%. Another hack is for olefin production. Ethylene or propylene must be free of moisture and other contaminants that can poison catalysts. Molecular sieves provide that dryness and keep the process stable.

In the pharmaceutical industry, I rely on molecular sieves to dry organic solvents or remove trace water from final products. Many active pharmaceutical ingredients degrade in the presence of moisture, so keeping them dry is key. That ensures product stability and efficacy. For the food industry, molecular sieves remove moisture from edible oils or sweeteners, thus preventing spoilage. They help maintain taste and extend shelf life. I also see them used in beverage-grade CO₂ purification, ensuring the gas meets strict purity guidelines.

Selecting the right sieve is like matching puzzle pieces. If I handle a polar molecule, I might choose a 3A or 4A sieve. For bigger molecules or non-polar species, I look at 5A, 13X, or carbon molecular sieves. Temperature and pressure conditions also matter. At times, I stack multiple sieve beds to remove different impurities in steps. That might combine carbon sieves with zeolite-based sieves. Each bed targets certain molecules.

Challenges happen when certain contaminants are too big or sticky, leading to partial pore blockage. I solve that by installing filter elements before the sieve bed or by setting up a regeneration cycle that uses higher temperatures or special purge gases. Sometimes I do chemical washing if the contaminant is especially stubborn. Good design and operation keep the system running smoothly.

If I compare molecular sieves with silica gel or activated alumina in these industries, I see that sieves reach lower dew points. That is vital in processes where even a small trace of moisture can ruin the product or the equipment. Their consistent pore size distribution also means I can fine-tune separations. This can lower operating costs because I do not have to run extra purification steps. All these hacks highlight why molecular sieves are so vital in real-world settings.

Conclusion

Molecular sieves are selective, reusable, and highly effective adsorbents. They help me achieve reliable purity and dryness in many applications with straightforward operation.