Crude oil separation is a complex process that demands advanced solutions. Molecular sieves play a crucial role in enhancing separation efficiency and product purity.

Molecular sieves, crucial in crude oil separation, help remove water and impurities, ensuring cleaner, higher-quality products. Their precise adsorption properties make them essential in the refining process.

As the crude oil separation process advances, molecular sieves continue to improve overall efficiency and reduce impurities in various stages of refining. Let’s explore how they work.

Understanding Molecular Sieves: Key to Efficient Crude Oil Separation?

Molecular sieves are fundamental to refining processes. Their ability to selectively adsorb molecules based on size and shape ensures efficient separation of crude oil components.

Molecular sieves, also known as adsorbents, effectively remove impurities from crude oil by using their selective adsorption capabilities, enhancing separation efficiency and product quality.

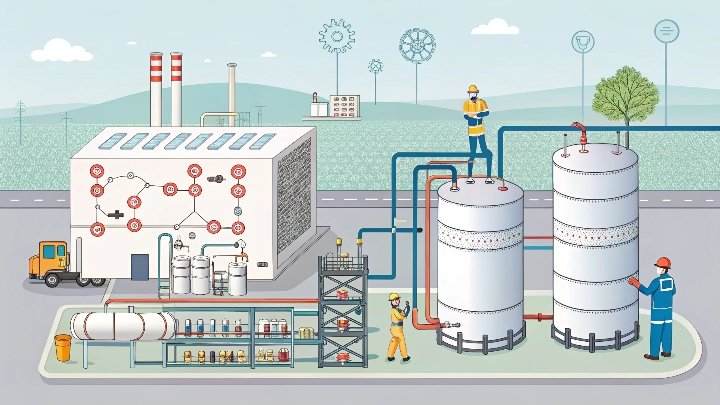

The primary function of molecular sieves in crude oil separation lies in their adsorption properties. These sieves have a unique structure with pores of nearly equal size, enabling selective adsorption based on molecular shape and size. When crude oil passes through these sieves, smaller impurities, such as water and gases, are trapped within the pores while larger hydrocarbons flow freely.

The removal of water from crude oil is particularly significant. Water can cause corrosion, catalyst poisoning, and lower product yield in downstream processes. Molecular sieves target and adsorb water molecules effectively, reducing water content from as high as 1000 ppm to less than 1 ppm, as reported by the International Association of Oil & Gas Producers. This leads to improved safety and efficiency in downstream processes, ensuring the stability of both equipment and product quality.

In addition to water removal, molecular sieves can also eliminate other impurities like hydrogen sulfide, mercaptans, nitrogen compounds, and oxygenates. These impurities, if left untreated, can hinder refining processes and lower the quality of end products. By removing them, molecular sieves help in improving the performance and lifespan of refining catalysts and equipment. This highlights the role of molecular sieves in enhancing not only the quality of the products but also the safety and longevity of refining systems.

How Molecular Sieves Enhance Oil Purity and Process Efficiency?

In crude oil refining, molecular sieves significantly improve both oil purity and overall process efficiency. Their advanced filtration mechanisms offer refined solutions for cleaner products.

Molecular sieves enhance oil purity by removing contaminants and impurities, allowing for more efficient refining. This leads to higher-quality products and better process efficiency in crude oil treatment.

Molecular sieves provide an essential function in refining crude oil by improving both the purity of the oil and the efficiency of the process. When crude oil is processed, it is often mixed with impurities like water, hydrogen sulfide, and other volatile compounds. These impurities not only affect the quality of the end products but can also interfere with the equipment used in refining.

By incorporating molecular sieves into the refining process, crude oil can be purified more effectively. As crude oil flows through columns filled with molecular sieves, these adsorbents trap and remove unwanted molecules based on their size and characteristics. The sieves have high selectivity, meaning they can specifically target water, sulfur compounds, and other small contaminants without adsorbing the valuable hydrocarbon molecules. This selective adsorption ensures that only the desired components are allowed to pass through, resulting in cleaner oil.

The process, known as dehydration, is particularly useful for removing water. As crude oil is dried, the water content is reduced to safe levels, improving the efficiency of the entire refining operation. The incorporation of molecular sieves reduces the likelihood of corrosion, catalyst poisoning, and contamination in downstream processes, which can significantly increase refining efficiency and reduce maintenance costs.

In addition to improving product quality, the use of molecular sieves also ensures a more efficient separation process in distillation. These sieves can assist in removing other impurities that might hinder the separation of crude oil into lighter and heavier fractions. The enhanced efficiency of molecular sieves in distillation can help maximize the output of valuable products such as gasoline and diesel while minimizing the production of unwanted byproducts.

The Future of Crude Oil Separation: Innovations in Molecular Sieve Technology?

The future of crude oil separation relies on innovations in molecular sieve technology. These advancements promise to further improve efficiency and product purity, creating new opportunities for the refining industry.

Future developments in molecular sieve technology aim to enhance adsorption capacity and efficiency, further optimizing crude oil separation and refining processes for cleaner, higher-quality products.

As technology continues to evolve, so does the potential of molecular sieves in the crude oil industry. Innovations in molecular sieve design and manufacturing are expected to significantly enhance their performance, offering even greater adsorption capacity, selectivity, and durability.

One area of innovation is the development of new materials with improved adsorption properties. Advances in nanotechnology and material science are leading to the creation of molecular sieves with smaller, more uniform pores, enabling better removal of even finer impurities. These new materials could also improve the sieves’ resistance to contamination, ensuring longer-lasting and more reliable performance in harsh refining conditions.

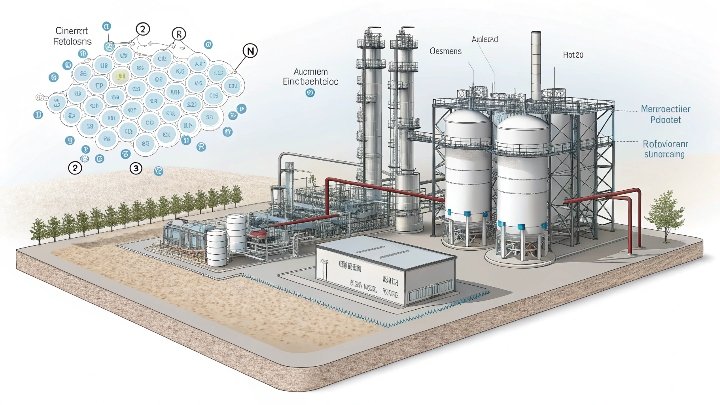

Another area of development is the integration of molecular sieves with other separation technologies, such as membrane filtration and pressure swing adsorption. Combining these technologies could lead to a more comprehensive and efficient crude oil treatment process, where molecular sieves handle the removal of small contaminants, while other methods tackle larger molecules or specific contaminants like CO2 or H2S.

The future of molecular sieve technology also includes increased automation and real-time monitoring. These advances will allow for more precise control of the adsorption process, ensuring optimal performance at every stage. Automated systems could also enable better tracking of impurity levels, enabling refineries to adjust their processes dynamically for maximum efficiency.

These innovations will not only improve the quality of the crude oil separation process but also reduce operational costs and environmental impact. By enhancing the efficiency of molecular sieves, refineries can achieve higher yields with less energy consumption and fewer byproducts, contributing to a more sustainable and cost-effective industry.

Conclusion

Molecular sieves are vital to crude oil separation, improving efficiency, product quality, and refinery safety. Innovations in their technology promise even greater benefits in the future.