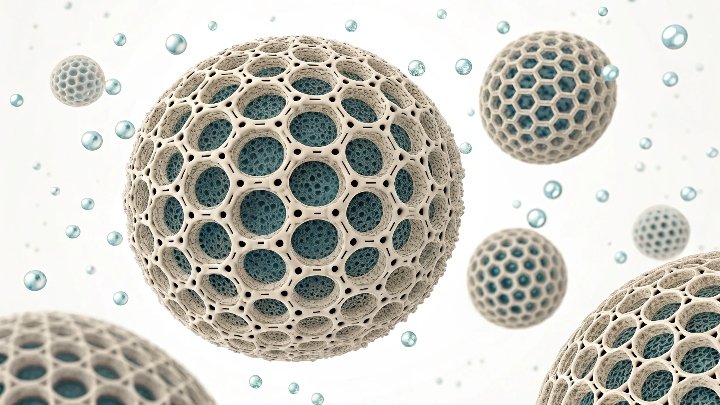

N-paraffin purification is a critical process in refining, and molecular sieves are the game-changers making it all possible. Let’s dive into how they work and why they are so effective.

Molecular sieves are revolutionizing N-paraffin purification. Their ability to separate pure n-paraffins through precise sieving mechanisms offers refineries increased efficiency and environmental benefits compared to traditional methods.

In the world of refining, molecular sieves have emerged as a must-have technology for efficient N-paraffin purification. But how exactly do they perform this magic? Let’s explore the science behind it.

The Science Behind N-Paraffin Purification: How Molecular Sieves Work Their Magic?

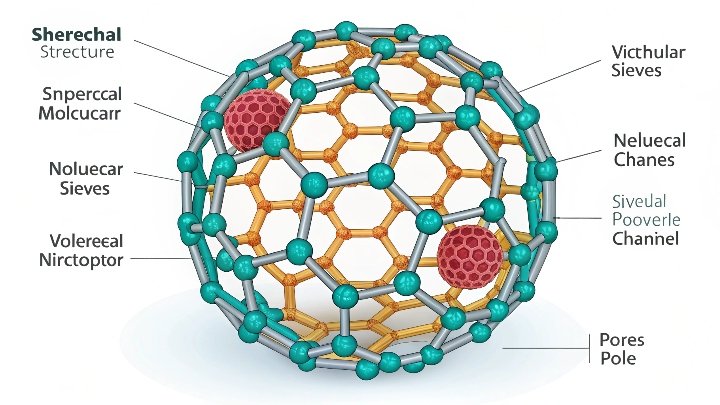

You might be wondering, how do molecular sieves actually work in N-paraffin purification? The answer lies in their pore size and selectivity.

Molecular sieves separate N-paraffins by using their specific pore sizes, allowing only certain molecules to pass. This precision makes them more effective than older methods like distillation or solvent extraction.

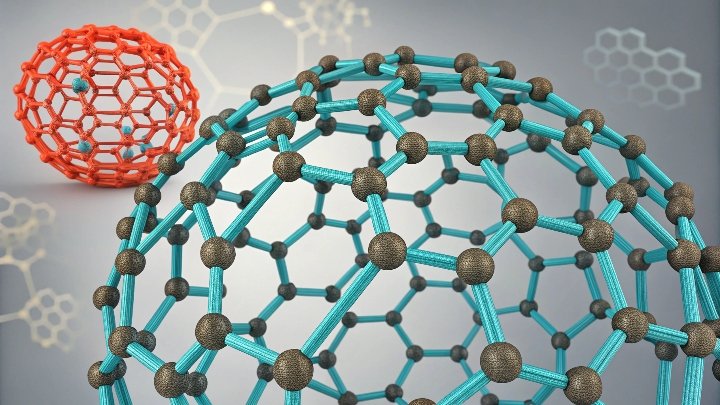

Molecular sieves are materials with highly uniform pores that are designed to selectively adsorb molecules based on size and shape. In N-paraffin purification, these sieves act as a filter, allowing smaller molecules like n-paraffins to pass through while blocking larger molecules such as iso-paraffins and other contaminants. The key to their effectiveness is their molecular structure, which provides a high degree of selectivity.

Compared to conventional methods such as distillation, which relies on boiling point differences, molecular sieves offer more precise separation. Distillation can be energy-intensive and often requires multiple stages, whereas molecular sieves operate efficiently at high temperatures and pressures, achieving separation in a single step. This results in lower energy consumption, reduced environmental impact, and better overall efficiency in the refining process.

Moreover, molecular sieves maintain their performance over long periods, ensuring that refineries can rely on them for sustained production without the need for constant maintenance or replacement. This long-term stability is a significant advantage, particularly in large-scale refinery operations where downtime can be costly.

In addition to their efficiency, molecular sieves are also more versatile. They can be tailored to specific applications by adjusting the pore size, making them suitable for a variety of purification needs, including the separation of other hydrocarbons or gases. This flexibility adds to their value in the refining industry.

Why Molecular Sieves are the Ideal Solution for N-Paraffin Purification in Refining?

Why choose molecular sieves over traditional methods for N-paraffin purification? The advantages are clear: higher efficiency, lower energy consumption, and better long-term stability.

Molecular sieves are ideal for N-paraffin purification because they provide high selectivity, operate at extreme temperatures and pressures, and are cost-effective in the long run. These qualities make them indispensable in modern refineries.

When it comes to refining processes, the use of molecular sieves in N-paraffin purification offers several advantages over conventional methods. One of the primary benefits is their ability to operate at high temperatures and pressures without losing performance. Traditional methods such as solvent extraction or distillation often require strict temperature control and multiple stages, which can be both energy- and time-consuming. In contrast, molecular sieves offer a more streamlined process, reducing operational costs and minimizing the environmental impact associated with excessive energy consumption.

Another key benefit is their high selectivity. Molecular sieves can be tailored to different applications by adjusting the size of their pores, ensuring that only the desired molecules, like n-paraffins, are absorbed. This precision ensures that refineries achieve the highest purity of their products, leading to better fuel quality and more efficient production of olefins. These higher-purity products are essential for improving the overall quality of refined materials and making them suitable for use in more advanced processes, such as polymer production or as feedstocks in petrochemical industries.

Furthermore, molecular sieves offer long-term stability, which reduces the need for frequent replacements or maintenance. This makes them more cost-effective in the long run, as refineries don’t have to worry about constant downtime or expensive replacements. The ability to maintain high efficiency over time is especially valuable in large-scale operations where reliability is crucial for maintaining production schedules and minimizing costs.

The versatility of molecular sieves also makes them an attractive option for refineries. They can be used for a range of applications beyond N-paraffin purification, including the separation of other hydrocarbons, gases, and even water. This adaptability allows refineries to streamline their processes and use a single material for multiple purposes, further increasing operational efficiency.

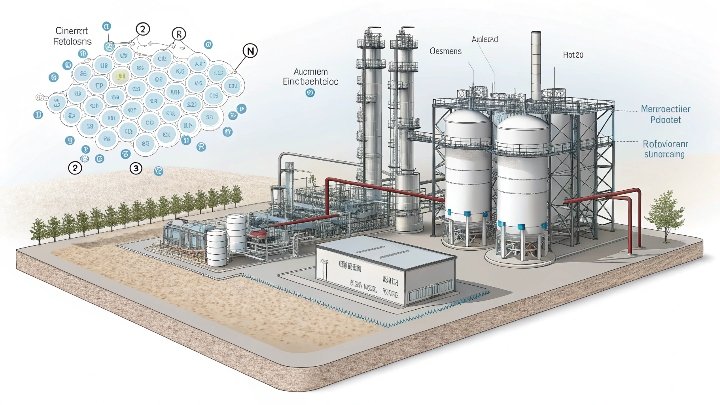

Real-World Applications: How Refineries Benefit from N-Paraffin Purification with Molecular Sieves

Now that we understand how molecular sieves work, let’s take a closer look at how refineries are benefiting from this innovative technology in real-world applications.

Refineries are seeing significant improvements in production efficiency, energy consumption, and environmental impact thanks to the use of molecular sieves for N-paraffin purification. These benefits are changing the way the industry operates.

The real-world applications of molecular sieves in N-paraffin purification are a testament to their transformative impact on the refining industry. In practical terms, refineries are able to achieve higher purity products while reducing operational costs and energy consumption. One of the most notable examples is in the production of high-quality fuel. By purifying n-paraffins to a greater degree, refineries can produce cleaner fuels that burn more efficiently and with fewer emissions. This is particularly important as the world moves toward more environmentally conscious energy solutions.

Moreover, refineries using molecular sieves for N-paraffin purification can optimize their entire production process. The ability to operate at higher temperatures and pressures, while maintaining high separation efficiency, means that refineries can run longer cycles with fewer interruptions. This results in increased throughput and reduced maintenance needs, which ultimately leads to higher profitability. The reduced need for energy and materials also helps refineries improve their sustainability efforts, reducing their carbon footprint and complying with stricter environmental regulations.

For example, a refinery that previously relied on distillation for N-paraffin purification may have faced challenges with energy efficiency, long processing times, and the need for multiple separation stages. By switching to molecular sieves, the refinery can streamline its operations and reduce the overall cost of production. This shift not only improves the refinery’s bottom line but also contributes to a more sustainable refining process.

The future of refining is closely tied to the adoption of advanced technologies like molecular sieves. As the industry continues to evolve and focus on sustainability, molecular sieves will play an increasingly important role in optimizing production processes and reducing the environmental impact of refining operations.

Conclusion

Molecular sieves are not just a technological advancement—they represent the future of N-paraffin purification in refining. Their precision, efficiency, and sustainability are transforming the industry for the better.