I used to wrestle with soggy biogas that jammed my pipelines. Now, I have a reliable fix.

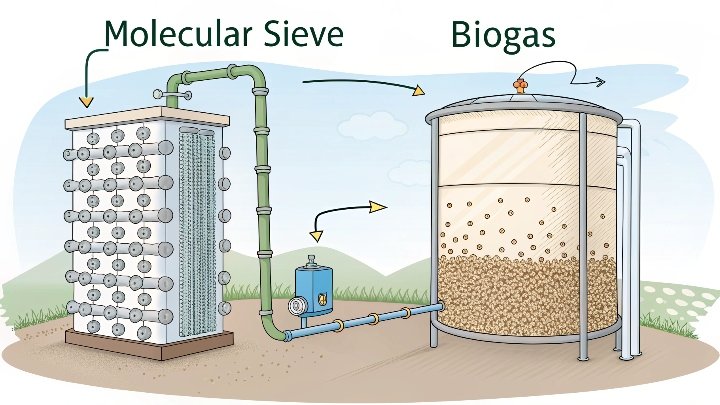

The best sieve for dehydrating biogas is 4A. It keeps the gas flow smooth, cuts corrosion risk, and helps save on costly repairs. It works by adsorbing moisture without harming the gas composition.

I remember when my wet biogas caused rust and clogged lines. That experience pushed me to find a better solution. Let me show you why molecular sieves matter.

Why Biogas Needs a Drying Superhero: The Role of Molecular Sieves?

I once saw condensation soak my equipment. It was a big headache.

Water in biogas leads to blockages, boosts corrosion, and hurts performance. A molecular sieve prevents these problems by trapping moisture so it does not harm pipelines.

Wet Biogas and Pipeline Chaos

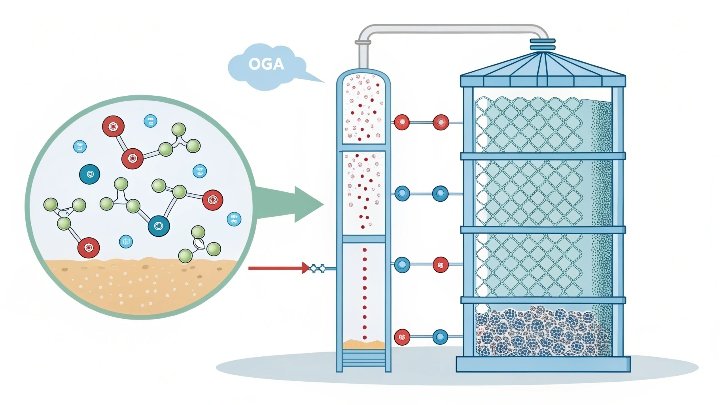

I learned the hard way that wet biogas disrupts operations and raises costs. Biogas, produced from anaerobic fermentation, often holds a lot of water. This water content becomes worse under high-temperature or medium-temperature fermentation. Then, as the biogas moves through pipes, changes in temperature and pressure cause water to condense. This lowers the dew point, which triggers more condensation inside the pipelines. At first, I ignored these small clogs, but they quickly piled up and turned into major blocks.

I realized that water inside biogas also interacts with hydrogen sulfide. This combination speeds up corrosion on pipes, valves, and flow meters. I saw rust eat away at expensive parts, forcing me to do more maintenance. A friend in my industry told me that even a small amount of water can cause big operational nightmares. I soon discovered he was right. The two-phase flow, a mix of gas and liquid, increases resistance in the pipeline. That raised my energy costs and slowed production.

When I found out about molecular sieves, I was skeptical. I wondered if they would affect the composition of my biogas or create new waste. But molecular sieves only use physical adsorption. That meant no changes to my gas composition or pollution concerns. This was important for me because I wanted to keep my operations as clean as possible. The selective adsorption feature also targets water molecules, so other components of the biogas remain intact. This was great news, because I did not want to lose valuable gas or introduce byproducts. That is how I realized these sieves acted like superheroes in my system. They were easy to install, too. With the right setup, they started removing water right away. Now I see them as essential guardians of my pipelines.

3A vs. 4A Molecular Sieves: Which One Saves the Day for Biogas?

I once tried 3A sieves but needed more efficiency. Then I tried 4A, and my system improved.

3A sieves and 4A sieves both dehydrate gas. But 4A offers higher water adsorption capacity and resists corrosion better, which makes it a top choice.

Comparing 3A and 4A for My Operations

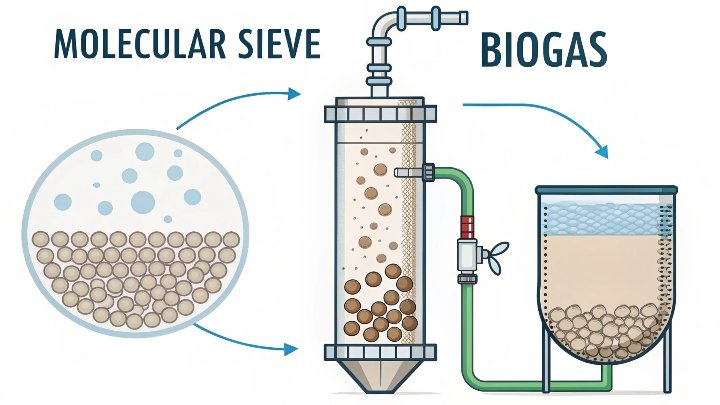

I started exploring 3A molecular sieves when I wanted to reduce water in my biogas. 3A can handle water molecules up to a specific size. It performed decently, but I found limitations. When my gas flow was higher, or the moisture content was heavier, I saw the 3A sieve struggle to keep up. I also noticed that over time, it became less efficient. I had to replace it more often. This meant more downtime for my operation.

I heard about 4A sieves from colleagues who worked in similar processes. They said 4A had a larger pore size and greater total adsorption capacity. This allowed it to hold more water, making it especially useful when biogas had high moisture. I decided to give it a try. I was impressed right away. My pipeline pressure stayed consistent, and there was less risk of flooding in the distribution system. The 4A sieve also resisted acid and alkali conditions better, which was vital because of the presence of hydrogen sulfide and other contaminants in biogas. I did not want to worry about corrosion or chemical attacks on my adsorbent.

I also realized that the 4A sieve’s selective adsorption capacity let it target water molecules without harming other valuable components. My methane concentration stayed stable. Another big bonus was the long service life. Once I installed 4A, I did not have to change it often. That saved me money on maintenance and gave me more time to focus on improving other parts of my process.

Below is a simple table comparing 3A and 4A based on my own experiences:

| Feature | 3A Sieve | 4A Sieve |

|---|---|---|

| Pore Size | Smaller, around 3Å | Larger, around 4Å |

| Water Adsorption | Good but limited under high load | Strong, even with high moisture |

| Chemical Resistance | Decent, may degrade sooner | Better resistance to acids and alkalis |

| Service Life | Shorter under tough conditions | Longer under similar or harsher conditions |

| Biogas Composition | Maintained but less stable over time | Maintained and stable for long periods |

This table helped me confirm that 4A is the right choice. It has a great combination of pore size, adsorption power, chemical stability, and service life. For someone like me, who wants to control costs and run a solid operation, 4A fits perfectly. It truly saves the day.

How Molecular Sieves Work Their Magic: The Science Behind Drying Biogas?

I became curious about the exact adsorption process. I wanted to see how these sieves keep my gas dry.

A molecular sieve is like a sponge with microscopic pores. It traps water molecules, so gas flows smoothly without blockages.

Understanding Adsorption and Why It Matters

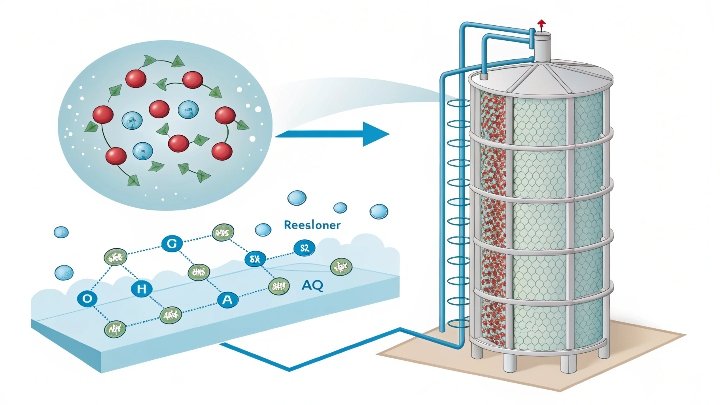

When I first handled molecular sieves, I pictured them as tiny, synthetic crystals. These crystals have a network of pores that capture specific molecules based on size and polarity. With 4A sieves, the pore diameter is about 4 angstroms, which is perfect for grabbing water but letting larger gas molecules pass. This selective adsorption is the reason it works so well for biogas dehydration. Water, which is a small molecule, gets pulled in and held by the sieve, while methane and carbon dioxide keep moving in the gas stream.

I also discovered that the adsorption process is entirely physical. There is no chemical reaction that changes my biogas. The water molecules stick to the inner surfaces of the sieve due to polarity and size compatibility. Because of this mechanism, the sieve remains stable when exposed to different temperatures or chemicals. It does not alter the gas composition, which is great for me. I do not have to worry about losing valuable components or adding impurities. My gas remains consistent, and the dew point is effectively reduced.

In practice, I set up a system where biogas passes through a packed bed of 4A sieves. As the wet gas flows in, water molecules get trapped inside the sieve pores. The dried gas exits without the risk of condensation. After a certain amount of time, the sieve will be saturated. That is when I switch to a regeneration step. Regeneration uses heat or pressure changes to remove water from the sieve, making it ready for another cycle. This cyclical process continues as long as I plan my operations with the right cycle times and flow rates. I love that it is an eco-friendly approach. I do not create harmful byproducts. I only remove moisture. And I can easily recover the sieve’s adsorption capacity by simple regeneration.

I am also careful with hydrogen sulfide, which is common in biogas. 4A sieves handle acidic conditions better. Some cheap adsorbents degrade quickly when exposed to acid or high temperatures. This is not the case with the 4A sieve, especially if it is of good quality. I have not seen it crumble or lose efficiency abruptly. This reliability is important, because I do not want to shut down my operation for unscheduled maintenance.

All these points explain the magic behind molecular sieves. They combine physical adsorption, selective pore size, and chemical resistance in one package. That is why they are so effective at drying biogas. They do not require any complicated setup or produce contaminated waste. Every time I implement 4A sieves, I see stable, trouble-free performance. That means lower costs, fewer headaches, and consistent productivity.

Conclusion

4A sieves solve wet biogas problems. I trust them to keep pipelines clear and operations strong.