The world of molecular sieves is vast and diverse. When it comes to dehumidification, 3A molecular sieves stand out as the preferred choice for many industries. If you are involved in the petrochemical, pharmaceutical, or environmental sectors, understanding the applications of 3A molecular sieves could significantly impact your operations.

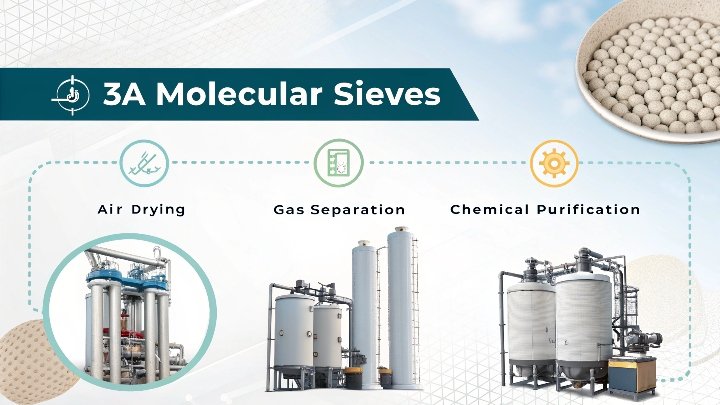

3A molecular sieves are vital for a wide range of applications in the industrial and commercial sectors. These sieves are known for their exceptional ability to adsorb water, making them essential in gas and liquid drying processes, moisture control, and environmental technology.

Many industries rely on 3A molecular sieves due to their ability to adsorb water without affecting other important components. This characteristic makes them perfect for industries that require precise moisture control, such as in the oil and gas, chemical, pharmaceutical, and food sectors. Let’s dive deeper into the key areas where 3A molecular sieves excel.

Drying Applications in Petrochemical and Refining Industries?

Drying in the petrochemical and refining industries is critical. Moisture can cause serious damage during the production process and affect the quality of the final products. Without effective drying, gases like ethylene, propylene, and acetylene could cause clogs or damage equipment.

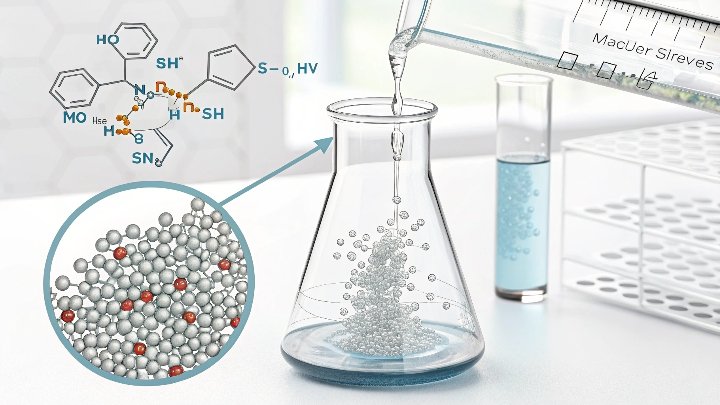

In the petrochemical and refining industries, 3A molecular sieves are extensively used for the deep drying of gases and liquids, including natural gas and petroleum.

The primary role of 3A molecular sieves in this sector is to remove moisture from the gas and liquid streams. In the petrochemical industry, gases such as ethylene and propylene are often used in polymerization reactions. Any trace of moisture can cause unwanted reactions, leading to product quality issues or equipment damage. Therefore, 3A molecular sieves play a crucial role in drying these gases to ensure smooth and efficient production processes.

In refining, 3A molecular sieves are also used to remove moisture from various petroleum products. This ensures that there is no water contamination in the final products, such as gasoline or diesel. Moreover, the moisture content in these products can affect their energy efficiency and cause corrosion in pipelines and tanks.

The use of 3A molecular sieves in these applications is not just about improving product quality but also preventing costly maintenance and extending the service life of the equipment.

Key Applications:

| Application | Description |

|---|---|

| Gas Drying | Removal of water from natural gas, ethylene, and propylene to prevent hydrate formation and ensure safe transport. |

| Liquid Drying | Used for drying liquids like ethanol and acetone, ensuring purity and preventing corrosion in the system. |

| Moisture Control in Petroleum Products | Prevents water contamination in gasoline, diesel, and other refined products, maintaining energy efficiency. |

Moisture Control in Industrial and Consumer Products?

Moisture can be harmful to both industrial products and consumer goods. In the industrial setting, moisture can affect the quality of chemical products, reduce the shelf life of pharmaceuticals, and even disrupt manufacturing processes. For consumer products, packaging with moisture can result in spoilage or malfunction.

3A molecular sieves are highly effective in moisture control across various industrial and consumer applications, ensuring product stability and quality.

In the pharmaceutical industry, for instance, 3A molecular sieves are used to remove moisture from raw materials and finished products. This ensures that the medicines retain their potency and do not degrade over time. Without proper moisture control, certain pharmaceutical products could lose effectiveness, leading to health risks.

Similarly, 3A molecular sieves are widely used in the food industry to preserve food items by absorbing excess moisture. This helps in preventing the growth of mold or bacteria that thrive in moist environments. The packaging of food and medicines often includes 3A molecular sieves to ensure freshness and extend shelf life.

In addition to food and pharmaceuticals, 3A molecular sieves are also critical in the electronics industry. They are used in the packaging of electronic products to protect against moisture damage, which could cause corrosion of sensitive components.

Key Applications:

| Application | Description |

|---|---|

| Pharmaceutical Drying | Ensures the stability and purity of raw materials and finished pharmaceutical products. |

| Food Preservation | Prevents moisture-related spoilage and extends the shelf life of packaged food items. |

| Electronics Packaging | Protects electronic components from moisture during storage and shipping. |

Specialized Uses in Energy and Environmental Technologies?

In the energy sector, moisture can cause issues in refrigeration and natural gas transportation. The ability of 3A molecular sieves to efficiently adsorb water has made them invaluable in these areas.

3A molecular sieves are also used in specialized applications like energy production, refrigerant drying, and even environmental technologies to improve system efficiency and reduce operational costs.

In the energy sector, 3A molecular sieves are used to dry refrigerants in HVAC and refrigeration systems. Moisture in refrigerants can cause ice formation, which can block the system and reduce its efficiency. By removing moisture, 3A molecular sieves help keep the systems running smoothly, preventing damage and improving the overall lifespan of the equipment.

Moreover, in natural gas processing, 3A molecular sieves are used to prevent ice formation or hydrate buildup during the transportation and storage of gas. The removal of moisture ensures the safe and efficient transportation of natural gas, which is critical to the energy supply chain.

In environmental technologies, these molecular sieves are also used to remove moisture from biogas in renewable energy applications. This prevents the formation of unwanted by-products and ensures that the biogas is used efficiently as a clean energy source.

Key Applications:

| Application | Description |

|---|---|

| Refrigerant Drying | Removes moisture from refrigerants to prevent ice formation and system damage. |

| Natural Gas Processing | Prevents hydrate formation in natural gas during storage and transport. |

| Biogas Moisture Removal | Ensures efficient use of biogas by removing excess moisture. |

Conclusion

3A molecular sieves are essential for maintaining product quality, system efficiency, and operational safety in numerous industries. Their ability to precisely remove moisture makes them indispensable across a wide range of applications.