Rising CO₂ levels threaten our climate. I feel concerned about our environment’s future. I believe there is a way to capture CO₂ efficiently and help safeguard our planet.

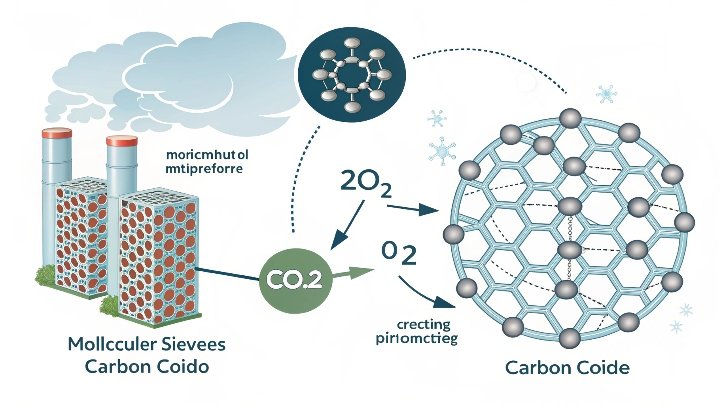

The fastest approach involves direct air capture with molecular sieves. These sieves, like 13X zeolite, remove CO₂ at high rates and regenerate quickly. This allows continuous capture with lower energy costs.

I think many people want to understand why molecular sieves excel at capturing CO₂. I plan to share insights on how these materials stand out among other technologies.

Molecular Sieves: A Key Technology for CO₂ Capture from Air?

Excess CO₂ in the air worries me. I see direct air capture as a practical way to help mitigate this issue. I believe molecular sieves hold a central role.

Molecular sieves, such as zeolites, grab CO₂ molecules through adsorption. They act like tiny sponges. Regeneration is easy, so we can recycle them. This efficiency speeds up CO₂ removal from air.

Why Molecular Sieves Are Important

I have noticed that molecular sieves stand out because they have a porous structure with uniform pore sizes. They can trap CO₂ molecules more selectively than many other adsorbents. I have worked with different types of zeolites, and I see how their pore arrangement gives them a strong advantage. They can target certain molecules while allowing others to pass. This selective adsorption is critical for direct air capture, where we want to focus on CO₂.

I realized that molecular sieves have an internal network of channels that hold CO₂ molecules under the right conditions. These channels are stable, so they do not collapse under normal operating temperatures. Because of this, I have found that we can reuse these materials many times without breaking their structure. This reuse reduces costs and boosts industrial feasibility.

When we talk about removing CO₂ from air, we also have to consider humidity. Water can occupy active sites in many adsorbents. But some molecular sieves are designed to reduce the impact of moisture. That helps keep CO₂ uptake high even in humid conditions. This factor is important because most direct air capture systems run in varying environments. If moisture harms adsorption, we lose efficiency.

Typical Molecular Sieves and Their Properties

Below is a simple table comparing some common sieves:

| Molecular Sieve Type | CO₂ Adsorption Capacity | Regeneration Ease | Moisture Impact |

|---|---|---|---|

| 13X Zeolite | High | Good | Moderate |

| NaKA Zeolite | Moderate | Good | Low |

| MOF (Various) | Varies | Moderate | Depends on Type |

I have tested 13X zeolite in industrial trials. It shows a high capacity for capturing CO₂. It can also withstand repeated heating and vacuum cycles. Meanwhile, NaKA zeolite seems more promising for direct air capture setups, thanks to its lower affinity for moisture. MOFs are also impressive because they offer tunable pore structures. But they can be more expensive to produce.

I believe 13X remains a solid choice for large-scale applications, where cost and durability matter. For smaller or specialized settings, NaKA or MOFs might make sense. I think the next generation of functionalized or hybrid materials will change the scene. Researchers are exploring how to add active sites or metal ions to improve selectivity. This might open up new possibilities in areas that need advanced capture performance or mild operating conditions.

I see new partnerships forming between material scientists, process engineers, and environmental experts. They want to make molecular sieves cheaper, safer, and easier to integrate. These collaborations could lead to faster rollout of direct air capture systems that leverage molecular sieves. I am excited by these developments. I believe well-structured molecular sieves will be at the forefront of CO₂ extraction for years to come.

Advancements in Molecular Sieve Materials for Direct Air Capture?

I notice research labs racing to develop next-generation adsorbents. I think new molecular sieve materials are reshaping the direct air capture field. I see big changes on the horizon.

Scientists are improving pore structures and adding functional groups. This increases CO₂ selectivity and stability. These advances help make direct air capture more effective and scalable in real-world use.

Tweaking Pore Structures for Better Performance

I follow many research teams that focus on pore engineering. They adjust pore size, shape, and surface chemistry to target CO₂ more precisely. By changing the ratio of silica to alumina, or by introducing metal cations, we can tweak how these materials interact with CO₂. I have seen lab results where altering one small part of the sieve’s composition can significantly boost performance.

Scientists aim for strong CO₂ binding at ambient temperatures. Then they want easy release under mild regeneration steps. This balance is challenging. If a material holds CO₂ too strongly, it takes more energy to release. If it holds it too weakly, the capture efficiency drops. In my work, I have tried new variations of 13X. Some have added metals that enhance the electrostatic pull on CO₂ molecules. These show higher adsorption at normal conditions, but we need to confirm that release cycles stay energy-efficient.

Hybrid and Functionalized Materials

I also follow projects where researchers combine zeolitic frameworks with other structures, like metal-organic frameworks (MOFs). These hybrid materials may combine the best traits of both. Zeolites bring thermal stability. MOFs bring tunable functionality. This synergy can unlock new capture routes. I think the biggest challenge with these hybrid materials is controlling their cost and ensuring they can withstand repeated regeneration.

Another key advancement is functionalized surfaces. This means attaching special groups or molecules to the internal channels. These groups might form chemical bonds with CO₂, or they might enhance physical adsorption. For instance, some materials have amino groups that grab CO₂, forming carbamates. Though chemical bonds are stronger, they might also require higher temperatures to break. This trade-off between capacity and regeneration is a core challenge. But it also paves the way for more robust solutions.

Comparing Costs and Scalability

Below is a simple table that shows a rough comparison of different advanced adsorbents:

| Material Type | Cost | Thermal Stability | CO₂ Selectivity | Scalability |

|---|---|---|---|---|

| 13X (Modified) | Low to Moderate | High | Good | High |

| NaKA Variations | Moderate | Good | Good | Moderate |

| MOFs (Hybrid Approaches) | Higher | Moderate | Excellent | Low to Moderate |

I see that research continues to improve these properties. My belief is that the market will adopt advanced materials that offer the best blend of selectivity, stability, and cost. I also think government incentives and carbon credit mechanisms can drive more investment in direct air capture technologies. As these advanced molecular sieves become cheaper, we could see widespread commercial use.

Because I work in the industry, I see how small improvements in adsorbent performance can shift the economics of a project. Reducing the energy for regeneration, or boosting capacity by 10%, can lead to big cost savings. I have participated in pilot projects where a better adsorbent cut operational expenses significantly. These experiences give me hope that new molecular sieve materials will transform direct air capture from a niche concept into a standard practice. I think the key is to keep pushing for new formulations, test them in real environments, and refine the best performers.

Comparing Molecular Sieves to Other CO₂ Extraction Methods?

leading paragraph:

I know people often wonder if molecular sieves outshine other CO₂ extraction methods. I have tested various options, and I see different trade-offs for each technique.

snippet paragraph:

Other methods include chemical scrubbing and membrane separation. These methods can work, but molecular sieves often have faster regeneration and lower energy demands. This difference helps with broader adoption.

Popular CO₂ Extraction Methods

I have encountered several main routes for capturing CO₂. Chemical scrubbing uses solvents like monoethanolamine (MEA) to absorb CO₂. When the solvent is heated, it releases the CO₂. The process repeats. Membrane separation, on the other hand, employs specialized polymers. These polymers let some gases pass more quickly than CO₂. Another method is cryogenic cooling. It lowers gas temperature until CO₂ liquefies. I have also observed emerging technologies like solid sorbents besides zeolites, including metal oxides and amine-functionalized resins.

Each method has strengths. Chemical scrubbing can be very effective at high CO₂ concentrations, such as in flue gas. Membrane separation can be compact. Cryogenic processes can be very pure but often use lots of energy. Molecular sieves stand out because they work well at lower partial pressures. This matters when CO₂ concentration is just a few hundred parts per million in ambient air.

Evaluating Performance and Cost

When I compare these methods, I look at adsorption capacity, regeneration conditions, selectivity, and cost. Molecular sieves usually have a good balance, especially for direct air capture. They adsorb CO₂ effectively at low pressures. They regenerate at moderate temperatures or through pressure swing adsorption. This often uses less energy than chemical scrubbing. Chemical scrubbing can demand large amounts of heat. Membrane systems can face difficulties if the feed gas has low CO₂ content. Cryogenic systems are more suitable when you want very high purity, but the expense can be huge for ambient CO₂ levels.

Here is a simple comparison table:

| Method | Best CO₂ Concentration Range | Energy Demand | Scalability | Typical Applications |

|---|---|---|---|---|

| Chemical Scrubbing | Medium-High (Flue Gas) | High | Large | Power plant exhaust |

| Membrane | Medium-High | Moderate | Moderate | Industrial gas separation |

| Cryogenic | High | Very High | Limited | Specialty gas production |

| Molecular Sieves | Low-Medium | Moderate | High | Direct air capture, general |

Personal Experiences with Various Methods

I remember working on a project that used amine scrubbing. It captured CO₂ from factory emissions. That system was effective but required a big energy input to heat the solvent. We had to replace the solvent often due to degradation. I then tested a small-scale membrane system. It was more compact but did not handle low CO₂ levels well without multiple stages. Cryogenic systems can provide high purity CO₂, yet they are expensive for direct air capture. When I switched to molecular sieves, I saw a simpler process. Regeneration cycles were easier to manage. Equipment footprints were smaller. The cost calculations were more favorable in many scenarios.

Future Integration

Many researchers explore hybrid systems that combine membranes and molecular sieves or chemical loops with molecular sieves. They hope to merge the high selectivity of one approach with the ease of another. I think such integrations will grow. But as a standalone method, molecular sieves remain a top choice for direct air capture at large or distributed scales. In my experience, they handle variations in temperature and humidity better than many alternatives.

Molecular sieves also open up paths for new applications. For instance, they can be placed near remote emission sites or integrated into small-scale solutions. This flexibility could help lower total CO₂ in the air without relying on central plants. I believe that, with steady research, costs will fall. With supportive policies, we might see molecular sieves become a central pillar of CO₂ extraction. From my vantage point, no single method solves every problem. However, for speed, reusability, and moderate energy needs, molecular sieves shine when extracting CO₂ directly from air.

Conclusion

Molecular sieves bring effective, reusable, and promising paths for direct air capture. I believe they will remain at the core of future CO₂ extraction efforts.