Adsorption dryers are essential in industries that require moisture removal from compressed air. But what type of molecular sieve works best for this critical task? Let’s find out.

The most commonly used molecular sieve for adsorption dryers is the 4A molecular sieve. Its high thermal and chemical stability, along with its selective adsorption properties, make it ideal for precision drying of compressed air.

While 4A molecular sieves are commonly used, it’s essential to understand the different types of molecular sieves and the factors that influence their selection. Let’s dive deeper into the specifics.

Commonly Used Types of Molecular Sieves in Adsorption Dryers?

Not all molecular sieves are the same. Choosing the right type for your adsorption dryer is crucial for optimal performance. Let’s take a closer look at the common types.

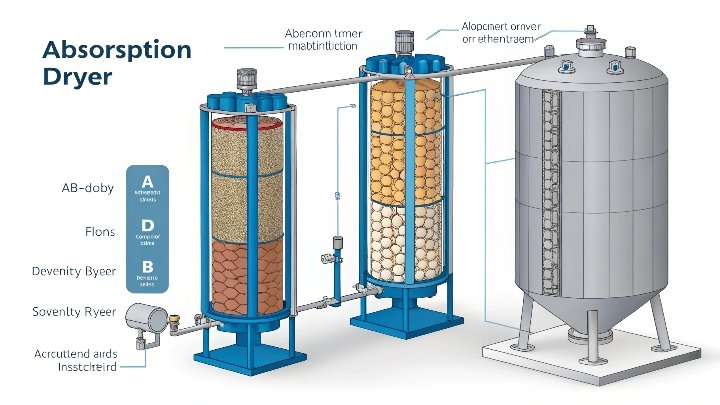

In adsorption dryers, 4A, 3A, and 5A molecular sieves are the most commonly used. Each offers unique advantages depending on the moisture content and specific needs of the compressed air system.

4A Molecular Sieve

The 4A molecular sieve is the go-to option for most adsorption dryers. It is known for its exceptional stability and selective adsorption ability. When compressed air, mixed with moisture, passes through the 4A sieve, it quickly adsorbs water molecules. This makes it ideal for high-precision drying. 4A sieves offer excellent performance even in challenging environments where thermal and chemical stability are important. They can handle varying moisture levels, providing consistent drying results. Additionally, 4A molecular sieves have the ability to regenerate effectively, ensuring long-term performance without significant degradation over time.

3A Molecular Sieve

The 3A molecular sieve is often used when a higher degree of moisture removal is required. It can adsorb smaller molecules, such as water, more effectively than other sieves. In situations where extremely dry air is needed, 3A is the best choice. It also performs well in applications involving gases that need to be purified to a very low moisture content.

5A Molecular Sieve

5A molecular sieves are usually selected for applications where larger molecules need to be separated. They have a larger pore size compared to the 4A and 3A sieves, making them suitable for drying gases or air with larger contaminants. While not as effective for moisture removal as the 4A or 3A sieves, they are often used in more specialized applications requiring the adsorption of specific larger molecules.

These sieves are selected based on the specific needs of the system. The 4A sieve, with its ability to handle various moisture levels, is the most popular choice. However, in situations where higher or lower moisture control is needed, 3A and 5A sieves can offer an advantage.

Key Factors Influencing Molecular Sieve Selection?

The right molecular sieve can make or break your dryer’s performance. Let’s explore the factors that determine the best selection for your needs.

When selecting a molecular sieve for an adsorption dryer, key factors include the size of the pores, adsorption capacity, moisture levels, and the operating temperature of the system.

Pore Size

One of the most critical factors in selecting a molecular sieve is the size of its pores. Molecular sieves are classified based on their pore size, and it is essential to match the pore size with the molecules you want to adsorb. For example, 4A sieves have a pore size of around 4 Ångströms, which allows them to effectively adsorb water molecules. However, if you are dealing with larger molecules, a sieve with a larger pore size, such as a 5A, might be more appropriate.

Adsorption Capacity

Another key factor is the adsorption capacity, which refers to the sieve’s ability to hold molecules. A higher capacity means the sieve can absorb more moisture before requiring regeneration. For systems with high moisture content, you may need a sieve with a higher adsorption capacity to maintain performance without constant regeneration.

Moisture Removal Needs

The level of moisture that needs to be removed from the compressed air also plays a significant role in sieve selection. If extremely dry air is required, then 3A or 4A sieves might be the best choice. However, if you are working with lower moisture removal needs, a 5A sieve may be more appropriate, depending on the size of the contaminants.

Operating Temperature

The operating temperature of the dryer also affects which sieve is most suitable. Some molecular sieves, like the 4A sieve, have higher thermal stability, allowing them to perform well in higher-temperature environments. If your system operates in extreme conditions, selecting a sieve with high thermal and chemical stability is crucial to ensuring long-term effectiveness and minimal regeneration downtime.

Considering these factors will help you make an informed decision about which molecular sieve is the best fit for your adsorption dryer. Choosing the right sieve is key to optimizing performance and ensuring the efficient operation of the dryer.

Applications and Industry-Specific Use Cases

Molecular sieves have wide-ranging applications in different industries. Let’s explore how these sieves are used in various sectors and why they are indispensable.

Molecular sieves are essential in industries that require precise moisture control, such as compressed air systems, natural gas purification, and biogas drying. Let’s take a look at their key uses in each sector.

Compressed Air Systems

In compressed air systems, moisture is a common issue. Without proper moisture removal, compressed air can lead to corrosion, reduced system efficiency, and equipment damage. Molecular sieves are used in dryers to ensure the air remains dry and free from contaminants. The 4A sieve is most commonly used in these systems, offering a high level of precision in moisture removal. It is crucial for applications where the air needs to meet stringent dryness standards, such as in food processing or electronics manufacturing.

Natural Gas Purification

In natural gas production, molecular sieves are used to remove impurities, including water and other gases, to ensure that the gas is of the highest quality. The 5A sieve is often selected for this application due to its ability to separate larger molecules like carbon dioxide and hydrocarbons. Molecular sieves play a vital role in ensuring that natural gas meets industry standards before it is distributed for consumption.

Biogas Drying

Biogas, produced from the decomposition of organic waste, contains moisture and other impurities that need to be removed for efficient use. Molecular sieves, particularly the 3A and 4A types, are used in biogas drying to remove moisture and other unwanted gases, such as carbon dioxide. This ensures the biogas is in the right condition for energy production or further processing.

Pharmaceutical and Food Processing Industries

In industries like pharmaceuticals and food processing, where precise environmental conditions are critical, molecular sieves help maintain the necessary dryness of the air or gas. 4A sieves are particularly important in these industries, where contamination or moisture can lead to product spoilage or failure. The ability to keep the air moisture-free ensures product quality and consistency.

Molecular sieves are indispensable across these industries, providing the reliability and efficiency needed for various applications. Their ability to precisely control moisture and remove contaminants ensures the optimal functioning of complex systems.

Conclusion

In conclusion, 4A molecular sieves are typically the best choice for adsorption dryers, but 3A and 5A sieves are also used in specific applications. Understanding the factors that influence sieve selection will help you make the best choice for your system.