Pressure swing adsorption (PSA) is a gas separation and purification technology that achieves separation by selective adsorption of gas components by adsorbents at different pressures. Pressure swing adsorption is mainly used to extract a certain target gas from a mixed gas or remove unwanted impurities.

Working principle of pressure swing adsorption

Adsorption stage: Under higher pressure, the mixed gas passes through an adsorption tower equipped with adsorbent. The adsorbent adsorbs the target gas on its surface according to the molecular size, polarity or adsorption force of the gas components, while other components pass through the tower bed to achieve the purpose of separation.

Desorption stage: When the adsorbent reaches saturation, the system releases (desorbs) the target gas on the adsorbent by reducing the pressure, thereby regenerating the adsorbent and restoring its adsorption capacity. At this time, the desorbed gas can be discharged or recycled.

Regeneration and switching: Multiple adsorption towers work alternately. When one adsorption tower is adsorbing, the other adsorption tower is regenerated by reducing the pressure. The system switches the pressure continuously, so that adsorption and desorption are alternated to achieve a continuous gas separation process.

Application of Pressure Swing Adsorption

Pressure swing adsorption technology has a wide range of applications in industrial gas separation and purification, including but not limited to:

Oxygen production: Extracting oxygen from the air, widely used in medical, metal smelting and chemical industries.

Nitrogen production: Extracting nitrogen from the air, used in chemical, food preservation, electronic manufacturing and other fields.

Hydrogen production: Extracting hydrogen from synthesis gas or other hydrogen-rich gases for hydrogen production, oil refining and chemical production.

Carbon dioxide removal: Removing carbon dioxide from natural gas, biogas and other gas streams for natural gas processing and biogas upgrading.

PSA technology has become an important gas separation and purification method in modern industry due to its simple operation, low energy consumption and ability to achieve continuous production.

Molecular sieve is used for pressure swing adsorption hydrogen production

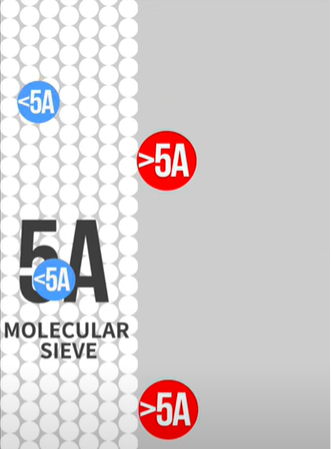

CNM 5A molecular sieve is widely used in industrial pressure swing adsorption hydrogen production.

Industrial hydrogen production mainly uses pressure swing adsorption hydrogen production equipment. The molecular sieve adsorbent filled inside absorbs impurity gases to purify hydrogen, and can produce hydrogen of different purities by changing the operating conditions. CNM 5A molecular sieve has high selective adsorption, fast adsorption speed, durability and no powdering, and efficient adsorption performance. Through pressure swing adsorption, gases and impurities such as carbon monoxide (CO), methane (CH₄) and nitrogen (N₂) can be removed to produce high-purity hydrogen. It can also adapt to hydrogen pressure swing adsorption devices of various sizes.

CNM 5A molecular sieve has been focusing on the adsorption field for 22 years. Follow CNM and welcome inquiries.