I once struggled to dry ethanol without wasting valuable product. That frustration led me to a proven solution. Now, I want to share it with you.

I choose 3A molecular sieves for industrial ethanol drying because their pore size of about 3 Angstroms can adsorb water molecules measuring 0.27 nanometers, while ethanol molecules are too large. That way, I prevent ethanol loss and keep it pure.

I want to share how I discovered the best molecular sieve for ethanol drying. I spent months experimenting with different adsorbent materials. Some wasted ethanol due to over-adsorption. Others did not remove enough water. Then I found 3A molecular sieves. Now, I have confidence in this method. Let me walk you through my lessons so you can avoid those pitfalls. You will see how 3A molecular sieves solve common drying problems and how they compare to other options. This sets the stage for deeper exploration. With this knowledge, you can streamline your process and conserve resources.

What is the drying method of ethanol?

I once believed that simple distillation was enough for removing water from ethanol. Then I discovered a more precise route. Let me outline it clearly.

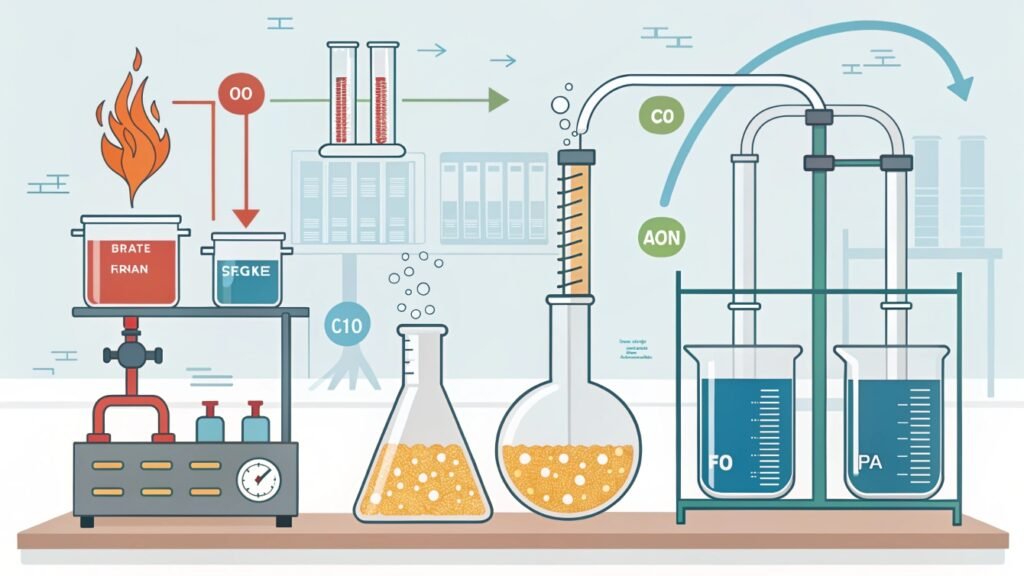

Ethanol drying involves removing water until the ethanol reaches a desired purity level. Common methods include azeotropic distillation and molecular sieves. Distillation alone often leaves some water. Molecular sieves solve this by adsorbing water without capturing ethanol.

Distillation is a familiar technique for separating liquids based on their boiling points. Ethanol and water form an azeotrope at around 95.6% ethanol by volume, which means you cannot easily get rid of the last bit of water through simple distillation. I faced this problem when I tried to push ethanol purity beyond that limit. The distillation method alone did not deliver the dryness I wanted. I started looking for an alternative to help me reach higher purity levels. That led me to the idea of using molecular sieves. These small, porous materials can trap water molecules and let ethanol pass freely. This extra step after distillation gave me the result I needed.

I noticed that combining distillation with a final adsorption step is an efficient way to remove residual water. During distillation, you remove most of the water. Then the molecular sieve tackles the small amount of water that still remains. This approach saves energy because you do not waste effort trying to distill everything to absolute dryness. You handle the bulk of separation with distillation and fine-tune the product with molecular sieves afterward. I remember reading about this in a research paper, which suggested that carefully designed sieve beds can bring ethanol purity up to 99% or more.

Here is a simple comparison table I created while planning my process:

| Method | Advantages | Disadvantages |

|---|---|---|

| Distillation | Good for bulk separation | Cannot surpass azeotropic limit easily |

| Molecular Sieves | Precise water removal beyond distillation | Must replace or regenerate the sieve |

From this table, it became clear to me that each method has a purpose. Distillation tackles the bulk separation, and molecular sieves handle precise water removal. I learned that using them together is often the best practice. After I made the switch, I noticed a drop in ethanol losses because 3A sieves selectively adsorb water. This helped me achieve higher purity and maintain an economical process. That is why I always recommend combining distillation and molecular sieves when people ask me about ethanol drying methods. It is straightforward, it conserves product, and it meets the goal of high-purity ethanol.

What is a molecular sieve for drying solvents?

I once wondered if molecular sieves were just tiny rocks that absorbed liquids. It turns out they are much more specialized. Let me explain.

A molecular sieve is a synthetic or natural material with uniform pores of a specific size. When used for solvent drying, it only adsorbs molecules smaller than its pore opening. This allows selective adsorption of water while leaving the solvent untouched.

I became fascinated with molecular sieves when I learned about their crystalline structure. Each sieve has channels or cages measured in Angstroms. If the molecule fits, the sieve adsorbs it. If it does not fit, it remains in the solution. This is especially helpful in solvent drying. In my early days, I used other forms of drying agents, like silica gel or calcium chloride. However, those materials did not offer the same selectivity. They sometimes absorbed more than just water. That led to product loss and extra purification steps.

When I discovered molecular sieves, I liked that they come in different types, such as 3A, 4A, 5A, and 13X. These numbers indicate their pore sizes in Angstroms. For ethanol drying, 3A is perfect because its 3 Angstrom pore size is large enough to take in water molecules of about 2.7 Angstroms, but too small for ethanol. If you pick 4A, you risk losing some of your ethanol to the adsorbent because ethanol is small enough to slip inside 4A’s pores.

I remember experimenting with 4A sieves once, thinking it might be more efficient. Instead, I noticed a drop in overall ethanol yield. That was frustrating, and it cost me time and money. I eventually switched to 3A for ethanol. With 3A, I got high-purity ethanol without sacrificing volume to the adsorbent. This advantage is key if you need to conserve your alcohol and achieve consistent results. I also learned that 3A sieves can be regenerated. That means I can heat them to drive off the adsorbed water and reuse them. This process is crucial for controlling costs.

In practice, molecular sieves are widely used in many industries. I have seen them in labs, pharmaceutical plants, and chemical manufacturing facilities. Because they are so selective, they streamline the purification process. This approach saves energy, reduces waste, and improves consistency. That is why molecular sieves hold a special place in solvent drying. They embody a simple concept but provide a powerful solution.

Here is a quick table showing a few typical molecular sieve types I have come across:

| Molecular Sieve Type | Pore Size | Common Use |

|---|---|---|

| 3A | ~3 Å | Drying polar solvents (e.g., ethanol) |

| 4A | ~4 Å | Drying gases, some solvent drying |

| 5A | ~5 Å | Adsorbing normal paraffins |

| 13X | ~10 Å | Air separation, CO2 removal |

This table guided me when I first explored molecular sieves. It shows at a glance why 3A is best for drying ethanol and why 4A might cause ethanol losses. Over time, I realized that choosing the correct type pays off in both purity and cost savings.

How do I choose a molecular sieve?

I remember feeling overwhelmed by so many adsorbent options. Then I learned a simple decision rule. Let me share it with you now.

Selecting a molecular sieve depends on your target molecule’s size and your need to exclude certain molecules. For ethanol drying, 3A is the safest choice because it adsorbs water, not ethanol.

When I started comparing different molecular sieves, I realized the importance of matching pore size to the molecules involved. Water molecules have a kinetic diameter of about 2.7 Angstroms. Ethanol molecules are bigger. If I pick a sieve that has a pore size larger than ethanol, I will lose some of my product. That is why 3A is the sweet spot for ethanol drying. It is big enough to trap water but too tight for ethanol to slip inside.

I learned that other factors matter as well. For instance, the presence of other contaminants can affect sieve performance. If there is oil or other heavy compounds, they might block the pores, reducing the adsorption capacity. Regeneration conditions also play a role. I must check the temperature limits for the sieve material to ensure I do not degrade it during regeneration. Another point is the equilibrium time. Some sieves need more contact time to adsorb water fully. The design of the adsorption tower or column also matters. I once operated a pilot system where the flow rate was too high. This limited the contact time and reduced the sieve’s efficiency. After adjusting the flow, I got better results.

Along the way, I also noticed that the cost of a sieve is not the only factor to consider. Cheaper sieves may have inconsistent pore sizes or lower quality control. This can lead to uneven results and more frequent replacement. High-grade 3A sieves often give me consistent performance and last longer, making them a better investment. Sometimes, I buy a slightly more expensive product that has a solid track record. That choice pays off in fewer disruptions and stable ethanol purity.

I also keep an eye on the shelf life. Moisture exposure during storage can partially saturate the sieve, so I store them in airtight containers or sealed packaging. This ensures that the sieves perform at their best when I finally use them. At the end of the day, choosing a molecular sieve is about balancing pore size, quality, and regeneration needs. If I want to dry ethanol, 3A is still my first recommendation. That single choice has saved me time and product losses. I encourage anyone in ethanol production to consider it before trying bigger-pore options.

Conclusion

3A molecular sieves give me the best way to dry ethanol without sacrificing yield or purity.