Sulfur in natural gas is more than just a nuisance. It corrodes pipelines, pollutes the environment, and even affects human health. But don’t worry, there’s a solution!

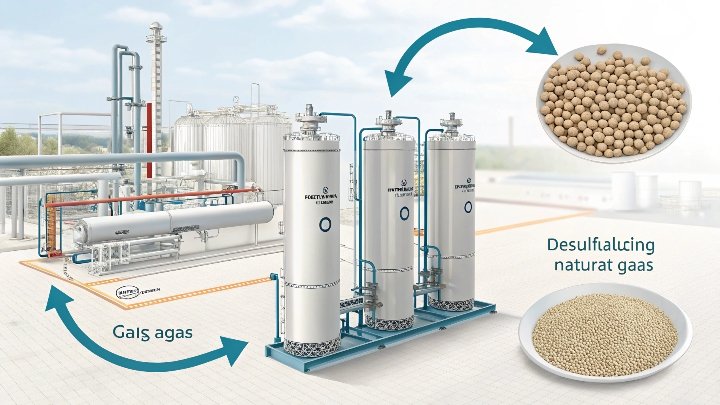

The CNM 13X molecular sieve is the top choice for removing sulfur from natural gas. Its high desulfurization efficiency and large adsorption capacity make it the go-to solution for this critical task.

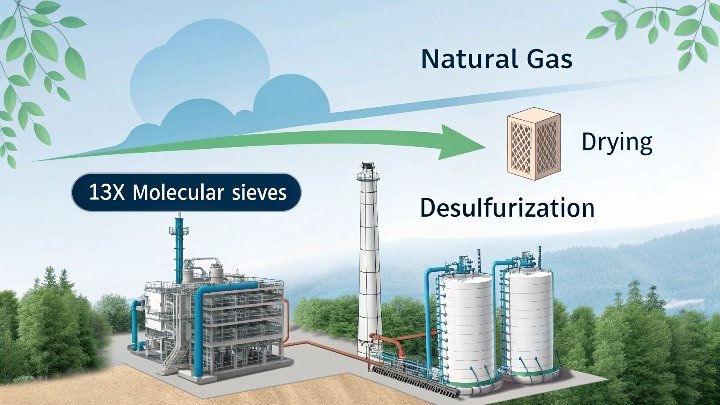

So, how exactly does this molecular sieve work its magic? Let’s dive into the science behind CNM 13X molecular sieve’s role in natural gas purification.

13X Molecular Sieve: The Sulfur-Slaying Superhero!

Natural gas is loaded with sulfur compounds that create problems for both the environment and industrial applications. Is there an easy fix to clean up this gas?

Yes! CNM 13X molecular sieve is a powerful solution that efficiently removes sulfur and other contaminants from natural gas, ensuring it’s ready for safe use in homes, factories, and energy plants.

When it comes to removing sulfur from natural gas, it’s not just about getting rid of the bad stuff. It’s about making sure the gas is safe, clean, and suitable for use across various industries. Sulfur compounds in natural gas can range from hydrogen sulfide to organic sulfur compounds, each one carrying its own set of challenges.

Hydrogen sulfide (H2S) is particularly problematic because it’s both toxic and corrosive. It can cause severe damage to pipelines and equipment, leading to expensive repairs and maintenance. But that’s not all; when burned, sulfur compounds in natural gas create pollutants like sulfur dioxide (SO2) which contribute to acid rain and have harmful environmental impacts.

This is where molecular sieves come in. Their unique ability to selectively adsorb molecules based on size and chemical structure makes them ideal for the task. The CNM 13X molecular sieve, in particular, stands out due to its large pore size, which allows it to trap sulfur compounds like hydrogen sulfide effectively. Not only does it have the capacity to adsorb these harmful compounds, but it also holds onto moisture that might otherwise affect the quality of the gas.

What makes the 13X sieve even more appealing is its regeneration capability. After it has adsorbed sulfur and moisture, it can be heated to release the trapped contaminants, making it reusable and cost-effective in the long run. This regeneration process also extends the life of the sieve, ensuring consistent performance over time.

The combination of these features makes the CNM 13X molecular sieve an indispensable tool in natural gas desulfurization. It not only helps meet environmental standards but also ensures that natural gas is safe to use in various industries, from energy production to petrochemical manufacturing.

The Science of Sweetening: How 13X Sieves “Trap & Zap” Sulfur!

How does a 13X molecular sieve manage to remove sulfur so efficiently? Let’s explore the science that powers its adsorption abilities.

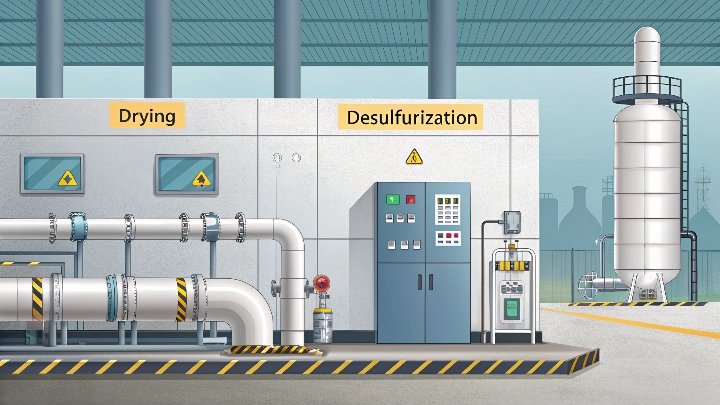

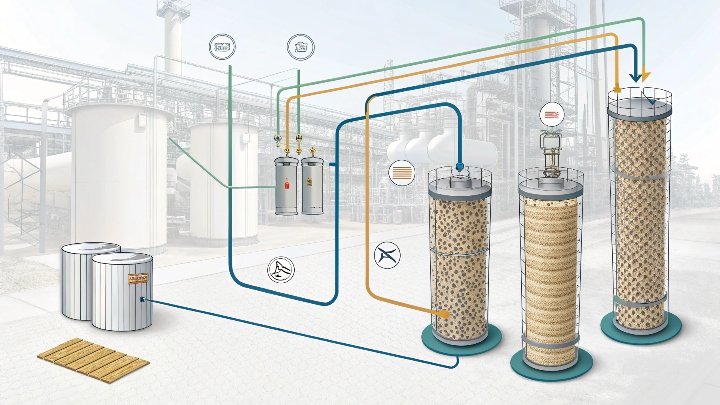

The CNM 13X molecular sieve uses a combination of physical and chemical processes to trap sulfur compounds and moisture in natural gas, transforming it into a cleaner, safer product for industrial use.

The CNM 13X molecular sieve works through selective adsorption, a process where certain molecules are attracted and held by the sieve’s surface. This process is heavily influenced by the size and shape of the molecules in question. The 13X sieve’s larger pores allow it to capture larger sulfur molecules, like hydrogen sulfide (H2S), while rejecting smaller molecules like methane.

Once natural gas flows through the sieve bed, the sulfur compounds get trapped in the pores of the material. These pores are created by the sieve’s crystalline structure, which is made of aluminosilicate material. This structure is highly efficient at attracting and holding onto sulfur molecules, effectively removing them from the gas stream.

In addition to physical adsorption, the CNM 13X molecular sieve also benefits from its ability to react with moisture in the gas. This is crucial because moisture can interfere with the sieve’s adsorption capacity. By adsorbing both sulfur compounds and water, the 13X sieve ensures that the gas is not only sulfur-free but also dry—perfect for use in various industrial processes.

The 13X sieve is particularly effective at desulfurization because of its high capacity for adsorption. It can remove large quantities of sulfur from natural gas before needing to be regenerated. This regeneration process involves heating the sieve to release the trapped sulfur, which can then be removed, allowing the sieve to be reused multiple times. This cycle of adsorption and regeneration makes the CNM 13X molecular sieve both efficient and cost-effective for long-term use.

The result is cleaner, sulfur-free natural gas that can be used for everything from powering homes to fueling industrial operations. The CNM 13X molecular sieve doesn’t just remove sulfur; it “sweetens” natural gas to meet the high standards required for safe and environmentally-friendly use.

Beyond Theory: Real-World Wins in Gas Processing & Beyond!

The CNM 13X molecular sieve isn’t just a theory in a lab. It’s already making a real impact across industries. But how well does it actually perform in the field?

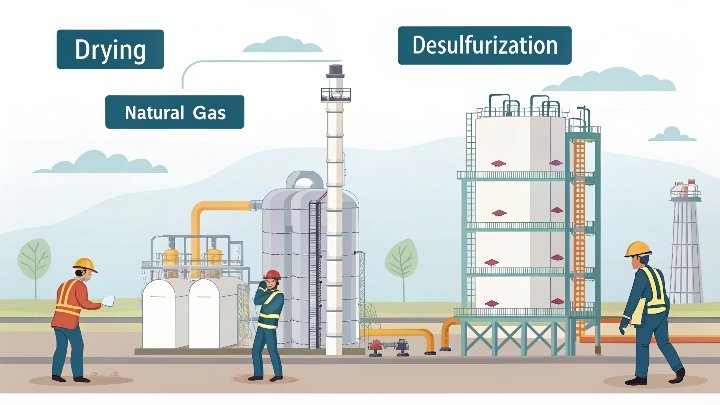

The CNM 13X molecular sieve has proven its worth in natural gas desulfurization, helping energy producers, gas processors, and manufacturers achieve cleaner, safer gas for industrial and residential use.

While the science behind the CNM 13X molecular sieve is impressive, the real test is how it performs in real-world applications. And the results speak for themselves. Many natural gas producers and processors rely on 13X molecular sieves for their desulfurization needs.

One of the major benefits of using the CNM 13X sieve is its ability to handle large volumes of gas. In large-scale natural gas processing plants, the sieve plays a critical role in ensuring that the gas meets environmental and industrial standards. It’s used in everything from upstream natural gas extraction to downstream gas treatment. The sieve’s high capacity for sulfur adsorption allows it to remove significant amounts of hydrogen sulfide, ensuring that the gas is both safe and environmentally-friendly.

Moreover, the 13X molecular sieve’s ability to regenerate has made it an invaluable asset in gas processing plants. Instead of replacing the sieve after a single use, plants can simply heat the sieve to remove the trapped contaminants, allowing the sieve to continue operating effectively for long periods. This reduces operational costs and improves efficiency, as the sieve can be reused multiple times before it needs to be replaced.

The sieve’s versatility extends beyond natural gas desulfurization as well. In addition to sulfur removal, it’s also used in other industrial applications like air separation, drying, and purification of gases. Whether it’s in biogas treatment, petrochemical processes, or air purification, the CNM 13X molecular sieve continues to prove its worth.

From a practical standpoint, companies that have incorporated the CNM 13X molecular sieve into their operations have seen a significant reduction in sulfur-related problems, such as pipeline corrosion and equipment damage. They’ve also observed improved product quality, with fewer sulfur emissions and cleaner gas for use in a variety of applications.

Conclusion

The CNM 13X molecular sieve is the ultimate solution for sulfur removal in natural gas, offering high efficiency, long-term cost-effectiveness, and environmental benefits.