I once struggled with wet chlorobenzene wrecking my chemical reactions. I felt frustration. Now I use a simple molecular sieve trick that keeps everything dry and boosts my results.

The best approach involves adding 3Å molecular sieves to chlorobenzene. These sieves trap water molecules in their pores, preventing moisture from ruining your reactions. This boosts purity, improves reaction speed, and increases yields. It is straightforward and effective.

I want to explore how molecular sieves dry chlorobenzene so effectively. This trick involves pore size, water adsorption, and smart solvent handling. Let me walk you through the steps, the benefits, and the deeper science behind this approach. Keep reading to unlock consistent success in your lab.

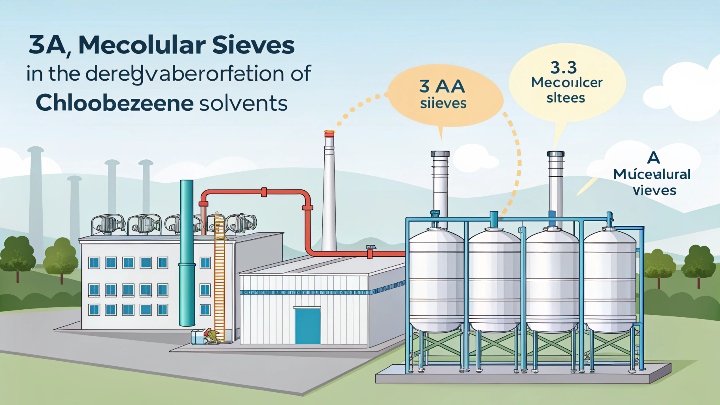

Why 3Å Molecular Sieves are the Chlorobenzene Drying Wizards?

I felt overwhelmed when my solvent stayed damp, even after heating. Now I rely on 3Å molecular sieves because they specifically target water. It changed my entire process.

3Å molecular sieves have pores sized for water molecules. They let chlorobenzene pass without trapping it. This selective adsorption is key for fast and thorough drying.

I want to highlight why 3Å sieves outshine other drying methods. They do not need complicated vacuum setups or extra steps. They just work quietly in the background, soaking up water. Let me show you the details.

3Å molecular sieves are powerful because their pore size is around three angstroms. That size is perfect for water molecules. It is too small for chlorobenzene, so the solvent stays untrapped. In my early experiments, I tried other drying agents like calcium chloride or magnesium sulfate. Those were messy and sometimes inconsistent. I also tried vacuum distillation, but that required extra equipment and time. Then I discovered the charm of 3Å molecular sieves. They are straightforward. I add them to the container, gently stir the mixture, and watch the moisture get pulled away.

I also noticed that 3Å sieves do not interfere with my reactions. They do not release any reactive byproducts that can alter the chemical pathway. That is important because moisture in chlorobenzene can create hydrochloric acid under heat. That acid can degrade reactants or form unwanted byproducts. By removing water at the source, 3Å molecular sieves prevent these problems. This means I get higher yields and a smoother reaction pathway.

The best part is their reusability. After use, I can heat them to drive off water. Then they are ready for another round of drying. This saves costs and streamlines my workflow. I keep a batch of 3Å sieves on hand for every new chlorobenzene batch. That single change improved my lab efficiency and gave me reliable results every time.

Step-by-Step: How to Dry Chlorobenzene Like a Lab Rockstar?

I used to ruin batches because I skipped proper drying steps. I felt defeated. Now I follow a clear procedure that turns my chlorobenzene into a perfect solvent.

The essential steps include removing large water droplets, adding 3Å molecular sieves, stirring to maximize contact, and monitoring dryness with simple tests. This routine guarantees a dry solvent.

I want to outline my entire process in detail. It is not complicated, but it is important to get each step right. Consistency leads to better final results. Let me share my method.

First, I make sure the chlorobenzene is free from obvious water droplets. If I see any droplets, I remove them using a simple pipette or by decanting. This prevents excess water from overwhelming the molecular sieves. Next, I weigh out the 3Å molecular sieves in a dry environment. I use gloves to avoid contaminating the sieves with moisture from my hands. Then I add the sieves directly to the chlorobenzene container. I prefer a wide-mouthed vessel that allows me to stir easily.

I use a magnetic stir bar or a gentle mechanical stir. This ensures maximum contact between the solvent and the sieves. I let the stirring go on for at least an hour. Sometimes I let it go overnight if I want extra dryness. During stirring, water molecules enter the pores of the 3Å sieves. This lowers the water content in the chlorobenzene. After that, I do a quick test. I might use a Karl Fischer titration if I want precise data. Sometimes I just run a small reaction to see if it forms any haze or side products. If the solvent is still not dry, I add fresh sieves or allow more stirring time.

In the final step, I separate the solvent from the sieves. I either filter or decant. The filtered chlorobenzene is now dry and ready for use. I store it in a sealed container to keep it from reabsorbing moisture. This procedure gives me consistent results and helps me avoid guesswork. It is simple, scalable, and reliable.

The Power of Dry Chlorobenzene: Applications and Why It Rocks?

I saw how wet chlorobenzene ruined sensitive reactions. I felt stuck. Then I learned the power of dry solvent, and it opened doors to new chemical pathways.

Dry chlorobenzene leads to better reaction yields, reduced byproduct formation, and a stable environment for moisture-sensitive compounds. It also supports polymer production, pharmaceuticals, and other specialized synthesis.

I want to explain why dry chlorobenzene matters in real-world scenarios. It is not just about lab success. It influences large-scale manufacturing, product purity, and final properties. Let me share some common applications.

Chlorobenzene is a versatile solvent used in many industries. I see it in the production of herbicides, dyes, and pharmaceuticals. In these processes, water often triggers side reactions. For example, certain intermediates may hydrolyze if water is present. That can lead to low yields or unwanted compounds. Dry chlorobenzene prevents this problem by providing a water-free environment for each step.

I also observe how dryness affects polymer synthesis. Some polymers form through sensitive condensation or coupling reactions. If moisture slips in, it can terminate the polymer chains prematurely. This results in shorter polymer lengths or inconsistent molecular weight distribution. By starting with dry chlorobenzene, I can keep these polymerization reactions stable and more predictable. That means final products with consistent properties. In large-scale facilities, that consistency is key for meeting quality standards and maintaining production schedules.

Pharmaceutical synthesis often needs dryness too. Many drug molecules are sensitive to hydrolysis or partial deactivation if water is around. Dry chlorobenzene gives a stable solvent medium for these critical steps. This helps me avoid complications in purification or downstream processing. It also reduces the risk of forming trace impurities that can impact safety or efficacy. Plus, removing moisture can reduce the formation of acidic byproducts that might degrade target molecules over time.

These advantages add up across the supply chain. Less rework, fewer failed batches, and smoother scaling from lab tests to full production. That is why I call dry chlorobenzene a game-changer. It brings reliability and consistency to processes that demand tight control.

Conclusion

Drying chlorobenzene with 3Å molecular sieves is a direct method for better yields and purity. I rely on it for consistent success in the lab.