LPG, or liquefied petroleum gas, is vital for energy production, but it’s often contaminated with sulfur compounds. How do we safely and efficiently remove these harmful elements?

5A molecular sieve is the secret weapon for desulfurizing LPG. Its precise pore structure effectively adsorbs sulfur compounds like hydrogen sulfide, ensuring cleaner, safer gas.

Desulfurizing LPG isn’t just about improving the gas quality; it’s about protecting equipment, enhancing safety, and ensuring environmental compliance. Let’s dive into why 5A molecular sieve is the best tool for this job.

5A Molecular Sieve: The Sulfur-Slaying Superhero of LPG!

Imagine trying to purify LPG without removing sulfur compounds like hydrogen sulfide (H₂S). What would happen? Equipment damage, lower efficiency, and even safety hazards!

5A molecular sieve is a powerful adsorbent that selectively targets sulfur compounds like H₂S. It works by trapping these impurities while leaving hydrocarbons untouched.

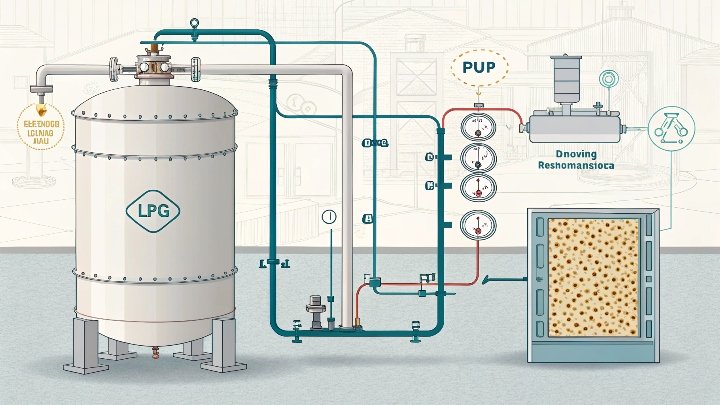

The role of 5A molecular sieve in desulfurizing LPG is crucial. Liquefied petroleum gas is often contaminated with acidic sulfur compounds, including hydrogen sulfide (H₂S), mercaptans, and organic sulfur. These compounds cause a series of problems: they poison catalysts in subsequent refining processes, corrode pipelines, and damage storage containers. Not to mention, they pose environmental risks.

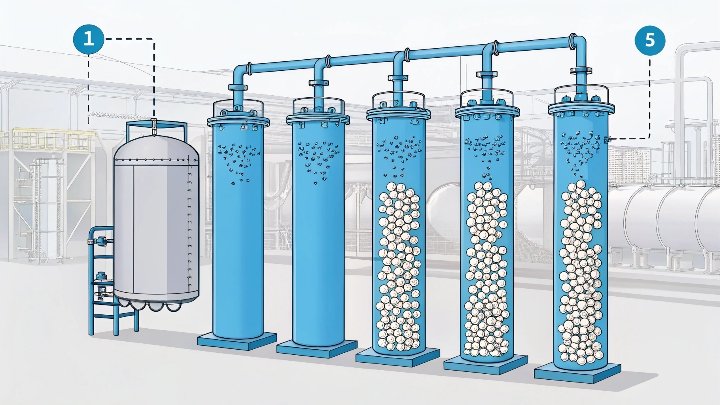

This is where the 5A molecular sieve shines. Its unique structure—composed of uniform pores around 5 angstroms in size—makes it perfect for adsorbing sulfur compounds. When the gas passes through the sieve, sulfur molecules are trapped in the pores while the LPG’s hydrocarbon components remain largely unaffected. This is essential because we want to remove the harmful sulfur without reducing the quality of the gas.

Let’s take hydrogen sulfide (H₂S) as an example. This compound is notorious for its corrosive properties and its negative impact on both human health and equipment. 5A molecular sieve works effectively by capturing H₂S molecules, preventing them from wreaking havoc in the gas stream.

One of the standout features of 5A molecular sieve is its high adsorption capacity. The sieve can hold a significant amount of sulfur, and it does this while maintaining a large surface area. This allows for longer service cycles before regeneration is required, offering an efficient and cost-effective solution for industries relying on LPG.

But it’s not just about sulfur removal. 5A molecular sieve also helps remove other impurities, such as carbon dioxide (CO₂) and small amounts of water. This makes it a versatile solution for improving the overall quality of LPG, leading to better performance in subsequent refining stages.

For the best results, 5A molecular sieve from CNM uses physical adsorption to ensure low levels of hydrogen sulfide and organic sulfur in LPG. These sieves also boast long lifespans, are easily regenerated, and maintain high removal rates, which is key for industries that rely on consistent, high-quality LPG.

The Science Behind 5A’s Magic: Pores vs. Pollutants!

The magic behind 5A molecular sieve is in its pores. But how do these tiny holes work to separate harmful pollutants from LPG? Let’s break it down.

The 5A molecular sieve has pores sized at around 5 angstroms, making it perfect for adsorbing sulfur compounds like hydrogen sulfide (H₂S) while allowing hydrocarbons to pass through.

Dive deeper Paragraph:

To truly appreciate the power of 5A molecular sieve, we need to understand how its pore structure works. The sieve’s pores, sized at approximately 5 angstroms, are small enough to trap polar molecules like sulfur compounds while letting non-polar molecules like hydrocarbons pass through.

This selective adsorption is a result of both size and polarity. Sulfur compounds like hydrogen sulfide (H₂S) are polar molecules, meaning they have positive and negative charges that allow them to bond with the surface of the sieve. Hydrocarbons, on the other hand, are non-polar and simply pass through the sieve without sticking.

Why is this important? If we didn’t have a precise molecular sieve like the 5A, we’d risk removing useful components from the gas, such as propane and butane. The beauty of 5A molecular sieve is its ability to pick out the bad stuff—like H₂S—without touching the good stuff. This keeps the quality of LPG high, ensuring that the gas retains its value for various industrial applications.

The sieve works in a physical adsorption process, meaning the sulfur compounds are held onto the surface of the 5A sieve without any chemical reactions occurring. This is particularly useful because it means the sieve can be easily regenerated. After adsorbing sulfur, the sieve can be heated or exposed to a vacuum to release the trapped sulfur and restore its adsorptive capacity.

This level of efficiency is key for industries looking to remove sulfur and other impurities from LPG in a cost-effective and sustainable manner. For example, CNM 5A molecular sieve helps ensure the long-term viability of gas-processing plants by maintaining high sulfur removal rates and extending the life of the equipment.

From Labs to Your Kitchen: How 5A Sieves Make LPG Safer & Greener!

We often don’t think about the technology behind the gas we use every day, but 5A molecular sieve plays a big role in making LPG safer and more environmentally friendly. How does it work?

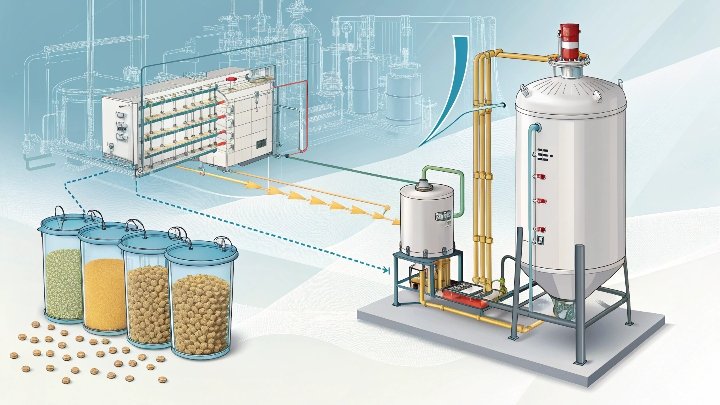

From lab-scale applications to large-scale LPG production, 5A molecular sieve helps make LPG cleaner by removing harmful sulfur compounds. This not only improves safety but also reduces environmental impact.

5A molecular sieve isn’t just for industrial use; it’s also making a big impact on the way we use LPG at home. The purity of LPG directly affects its combustion process. When sulfur compounds like hydrogen sulfide (H₂S) are present in the gas, they can lead to incomplete combustion, producing harmful emissions like sulfur dioxide (SO₂). These emissions contribute to air pollution, acid rain, and other environmental issues.

By removing these sulfur compounds from LPG, 5A molecular sieve helps ensure that the gas burns cleaner. This results in fewer emissions, making LPG a more environmentally friendly energy source. Moreover, when sulfur is removed, the likelihood of corrosion in gas burners and pipes is reduced, leading to longer-lasting, more efficient equipment.

On a larger scale, the role of 5A molecular sieve in refining LPG is critical. Industries that rely on LPG, such as chemical manufacturing and power generation, need a consistent supply of high-quality gas. The 5A molecular sieve’s ability to remove sulfur compounds ensures that these industries can operate smoothly and efficiently, without the risk of catalyst poisoning or equipment damage.

In addition, the use of 5A molecular sieve also helps in meeting environmental regulations. As global standards for emissions tighten, the need for clean-burning fuels becomes more important. 5A molecular sieve plays a key role in helping companies comply with these standards by removing sulfur and other contaminants from LPG before it is used.

Conclusion

5A molecular sieve is essential for removing sulfur from LPG, making it cleaner, safer, and more environmentally friendly for industrial and everyday use.

脱硫使用-5A-型分子筛-9.jpg)