I once faced soggy toluene that ruined my experiments. I felt stuck. Then I found a molecular sieve trick that changed everything.

The best approach is to use 3Å molecular sieves. They pull moisture away from toluene through physical adsorption. This leaves you with toluene that has less than 50 ppm water.

I used to think that toluene drying was too complicated or required fancy lab equipment. But once I tried 3Å molecular sieves, everything changed. I saw how a simple physical adsorption process could achieve moisture levels under 50 ppm. That is game-changing for me. My reactions improved, and my costs went down because I did not need extra purification steps. Let me show you what makes 3Å sieves so special, how you can apply them step by step, and why dry toluene changes everything in labs and industries.

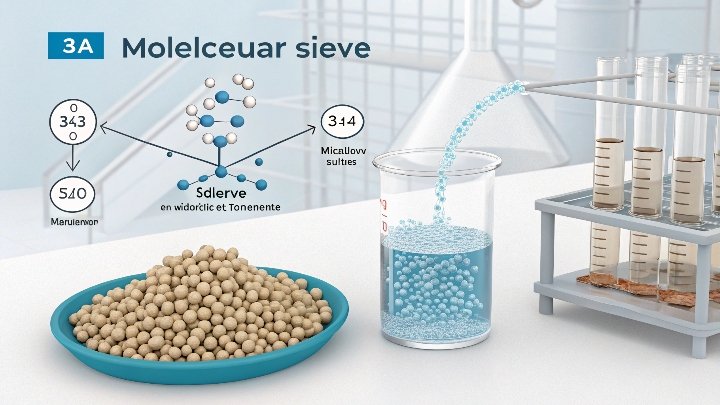

Why 3Å Molecular Sieves are the Toluene Drying Superheroes?

I once underestimated the power of 3Å molecular sieves. I tried other methods, but those gave me half-dry toluene. Then I realized 3Å sieves are the real deal.

3Å molecular sieves excel because their pore size is perfect for trapping water molecules but not toluene. That means they selectively remove moisture without changing toluene’s properties or leaving residue.

I learned that 3Å molecular sieves have a pore size of about three angstroms. That means they allow small molecules like water to enter, but they keep bigger molecules out. I use them to remove trace moisture in toluene. This stops unwanted reactions in my processes.

I want to clarify how they do this. They rely on physical adsorption. Water molecules stick to the interior surface of the sieve. The interior is full of tiny pores. Toluene molecules stay mostly outside because they are bigger. This selective adsorption leaves me with a purer solvent. I see the difference in my final product. The dryness can reach below 50 ppm of water. That is a big deal.

I also notice that 3Å molecular sieves do not produce byproducts. They do not add anything to my toluene. They only take water out. I see no extra catalysts or chemicals. This is safer for my lab. This is also more eco-friendly because there is no chemical waste.

I also notice that the pore size difference is the key to ensuring water molecules get trapped, while toluene remains unaffected. This detail cements 3Å sieves as an ideal choice.

Key Benefits to Keep in Mind

| Benefit | Description |

|---|---|

| Selective Adsorption | 3Å sieves only capture water, leaving toluene untouched. |

| High Precision Drying | They reduce water content down to under 50 ppm. |

| Eco-Friendly | They do not introduce harmful byproducts or cause waste. |

| Cost-Effective | You can regenerate them for repeated use, saving money. |

I like how cost-effective they are. After each cycle, I can often regenerate them by heating. Then I can reuse them. That reduces my expenses and my environmental impact. For me, 3Å molecular sieves are a game-changer in toluene drying.

Step-by-Step: Master the Art of Drying Toluene Like a Pro?

I once rushed my toluene drying process. I got poor results and wasted time. Then I followed a clear step-by-step approach. My toluene stayed crisp and consistent.

Gather your toluene, prepare 3Å molecular sieves, pre-dry your container, and add the sieves. Let them adsorb moisture for a set time. Then test water content. If it’s low enough, you’re good to go.

I like having a clear process so I do not forget anything. The first step is to make sure my 3Å molecular sieves are properly activated. This means I heat them to drive off any residual moisture. For me, this often involves placing them in an oven at around 200°C for a few hours. This step is crucial. If the sieves are not activated, they will not adsorb as much water from my toluene.

Step 1: Preparation

I gather my toluene in a clean container. I ensure that the container is dry. Even small droplets of water on the container walls can interfere with my drying efforts. I weigh the appropriate amount of sieves based on the volume of toluene. My usual ratio might be a few grams of sieves per liter of solvent, but this can vary.

Step 2: Activation

Before adding the sieves, I activate them. Some people skip this step, but I do not. I think it is essential. I place the sieves in a shallow tray and heat them. Then I let them cool in a desiccator. This stops them from picking up moisture from the air.

Step 3: Contact Time

I add the cooled, activated sieves to the toluene. I seal the container to block moisture from the atmosphere. I swirl the mixture gently or leave it to stand. I prefer to let it stand overnight, but I may check the dryness after a few hours. The contact time depends on how wet the toluene was in the beginning. If the water level was very high, I leave it longer.

Step 4: Verification

I test the water content with a simple method like a Karl Fischer titration or a moisture meter. If the reading is acceptable, I separate the sieves from the toluene. The solvent is then ready for use. If it is still too high, I repeat the process with fresh activated sieves. This method ensures I get the dryness level I want. I see consistent results, and I do not worry about unpredictable moisture levels.

The Magic of Dry Toluene: Why It Matters in the Lab and Beyond?

I once overlooked how damp toluene could cause side reactions. I wasted materials and time. When I dried it properly, I saw better yields and more stable products.

Dry toluene helps ensure that reactions are consistent. Moisture can alter reaction paths and cause lower yields. When toluene is dry, results are reproducible and stable. This matters in labs and industries.

I think dry toluene is not just a convenience. It is a critical factor in many reactions. When moisture is present, side reactions can happen. Water can trigger acid catalysis in certain processes. This creates unwanted byproducts. Then I have to spend time on purification. My yields suffer. My costs rise. So controlling moisture is vital.

Reactions in the Lab

In my experience, small-scale lab experiments need consistent solvents. A small amount of water can change reaction kinetics. It can shift the pH in acid-base reactions. It can even lead to incomplete reactions. When I first started, I overlooked this detail. My data was inconsistent. Then I realized the culprit was water in my solvent. After I switched to dry toluene, my results became reproducible. I got fewer complications and my reaction routes stayed on track.

Industrial Impact

On a larger scale, I see how industries need stable, dry solvents for consistent product quality. If toluene has moisture, it can degrade catalysts, produce undesired color changes, or reduce shelf life of the final product. This can hurt the bottom line. Dry toluene keeps each batch uniform. That helps me uphold quality standards. It also reduces the risk of acid catalyzed side reactions that lower product grade. I find that major manufacturers rely on 3Å molecular sieves for a reason. They get a reliable method to remove trace water without introducing contaminants. This approach helps them avoid extra process steps or chemical treatments. That saves time and money. So whether it is a small bench-top experiment or a large-scale production run, I see how dry toluene matters.

Conclusion

I trust that 3Å molecular sieves are the simple, clean, and cost-effective way to keep toluene dry. I see higher yields, stable results, and fewer production headaches.