Gas separation is an essential process in many industries, and carbon molecular sieves are becoming more and more popular. But what makes them so effective? Let’s dive in and find out!

Carbon molecular sieves are incredibly versatile. They are used in industries like chemical production, petroleum, and even environmental protection. Their ability to separate gases with precision makes them essential in various applications.

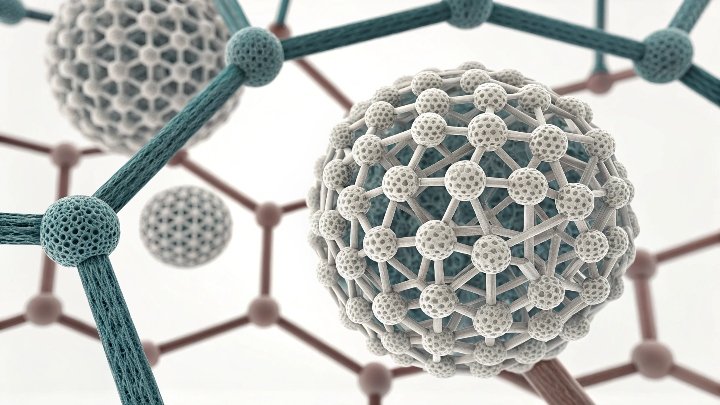

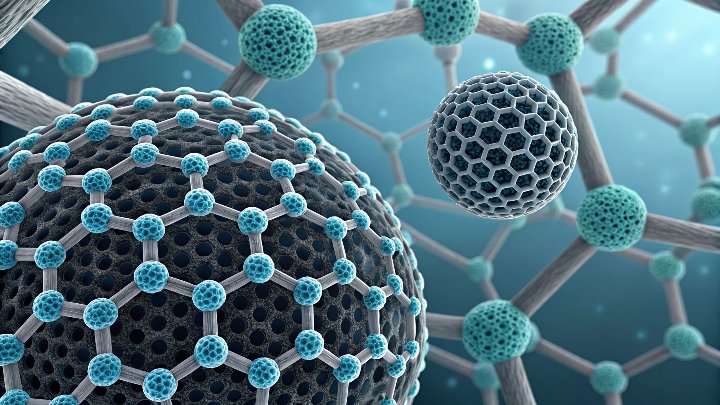

Carbon molecular sieves are often overlooked, but they’re a key player in many industries. In fact, their magic lies in their structure—tiny pores that selectively absorb molecules, allowing them to perform various tasks, like nitrogen production or environmental purification. These sieves are essential to industries such as biogas production, hydrogen storage, and organic solvent recovery. Let’s look at how carbon molecular sieves work their magic in different sectors.

Gas Separation Sorcerer: Turning Air into Liquid Gold!

Gas separation is one of the most common applications for carbon molecular sieves. By separating oxygen and nitrogen in the air, these sieves provide nitrogen for use in many industries. But how exactly do they do this?

Carbon molecular sieves separate gases based on molecular size and affinity, effectively isolating nitrogen from oxygen. This is crucial in industries like metallurgy and electronics, where high-purity nitrogen is needed.

Carbon molecular sieves function through a process called pressure swing adsorption (PSA). When air passes through the sieve, the nitrogen molecules are separated from the oxygen molecules. The sieve has a strong attraction for oxygen molecules due to its pore structure, allowing it to absorb oxygen and release nitrogen. This process is incredibly efficient, with high recovery rates and long service life, which is why these sieves are preferred in industrial nitrogen generators.

How it works

The carbon molecular sieve is essentially a finely tuned machine designed to isolate nitrogen. Through PSA, it uses its microscopic pores to adsorb oxygen and release nitrogen. This separation can occur at various pressure levels, ensuring the gas mixture is purified to meet industry standards.

| Application | Description | Industries Benefiting |

|---|---|---|

| Gas Separation | Separates oxygen from nitrogen to produce high-purity nitrogen. | Electronics, Metal Heat Treatment, Chemical Production |

| Adsorption & Storage | Adsorbs gases like hydrogen, methane, and CO2. | Hydrogen Storage, Natural Gas Purification, Carbon Capture |

| Compressed Gas Purification | Removes impurities like CO2 and moisture. | Medicine, Food Preservation, Electronics Manufacturing |

Eco-Warrior Mode: Cleaning Up Biogas & Capturing Carbon!

As concerns over environmental pollution grow, carbon molecular sieves are also stepping up to the plate. They’re playing an essential role in cleaning up biogas and capturing carbon dioxide (CO2).

These sieves can efficiently remove CO2 from biogas, helping to purify it and make it more suitable for use in energy production. They’re also key in capturing carbon, reducing greenhouse gas emissions.

Biogas production is on the rise, especially in landfills where methane gas is abundant. However, biogas typically contains impurities, including CO2, which can reduce its energy potential. Carbon molecular sieves are used to remove CO2, allowing the biogas to be refined into a cleaner, more effective energy source. The sieves trap CO2 in their pores, leaving behind methane, which is then used for energy generation.

In addition to biogas, these sieves are also critical in carbon capture technologies. With climate change becoming a global priority, capturing CO2 from industrial emissions is crucial. Carbon molecular sieves effectively trap CO2, helping industries reduce their carbon footprint.

Applications in Biogas and Carbon Capture

The use of carbon molecular sieves in biogas and carbon capture is expanding. These sieves are highly effective at removing impurities, ensuring that biogas can be used as a cleaner source of energy. Similarly, in carbon capture, sieves trap CO2, preventing it from entering the atmosphere.

| Application | Description | Industries Benefiting |

|---|---|---|

| Biogas Purification | Removes CO2 and other impurities from biogas. | Energy Production, Waste Management |

| Carbon Capture | Captures CO2 from industrial emissions. | Oil & Gas, Power Plants, Cement Production |

Hydrogen Economy’s Secret Weapon: Fueling a Green Future!

With the rise of the hydrogen economy, carbon molecular sieves are becoming a critical component. Hydrogen storage is one of the biggest challenges facing the industry, and these sieves play a major role in solving that problem.

Hydrogen, a clean fuel for the future, can be stored and transported efficiently with the help of carbon molecular sieves. They help prevent contamination and ensure purity.

Hydrogen storage requires high-purity conditions, and carbon molecular sieves are ideal for this. By adsorbing impurities like moisture, they help maintain hydrogen purity, making it safe for use in fuel cells and other applications. The ability of these sieves to separate and store gases like hydrogen is essential for the widespread adoption of hydrogen as a clean energy source.

Furthermore, these sieves are used in hydrogen purification processes, ensuring that only the highest quality hydrogen is used in fuel cells. This is vital for achieving the efficiency needed in green energy production.

Hydrogen Storage and Purification

Carbon molecular sieves are specifically designed to adsorb gases such as hydrogen and methane. This makes them ideal for the growing hydrogen economy, as they ensure that hydrogen remains pure and contamination-free during storage and transport.

| Application | Description | Industries Benefiting |

|---|---|---|

| Hydrogen Storage | Stores hydrogen safely and efficiently, preventing contamination. | Hydrogen Energy, Fuel Cells, Clean Transportation |

| Hydrogen Purification | Removes impurities from hydrogen to ensure purity. | Fuel Cells, Clean Energy Production |

Conclusion

Carbon molecular sieves are key players in many industries, from gas separation to environmental protection. Their ability to separate, store, and purify gases makes them essential in today’s industrial world.