Struggling with inconsistent gas purity[^1] in your air separation unit? This instability can disrupt your entire production line. The fix might be simpler than you think: your molecular sieve[^2].

Gas purity fluctuates because standard molecular sieve[^2]s have inconsistent pore sizes[^3], failing to separate gases effectively. A high-performance sieve, like a 13X-APG[^4], uses precisely engineered channels to selectively capture impurities like CO₂ and water, guaranteeing stable, high-purity gas output from your air separation unit.

It’s a frustrating situation. You've invested heavily in top-tier air separation equipment, yet the final gas purity is all over the place. One day it's perfect, the next it's below spec. You check the compressors, the heat exchangers, and the control systems, but can't find the root cause. This constant firefighting costs time and money, and it creates uncertainty in your supply chain. You start to wonder if you can ever achieve the stable, reliable production you need.

This inconsistency points to a deeper issue, one that many overlook. The problem often isn't in the big machinery, but in the small pellets working silently inside your purification vessels[^5]. Let's break down why your choice of adsorbent[^6] is so critical. We need to look beyond the hardware and focus on the very heart of the purification process: the molecular sieve[^2].

How Do Standard Molecular Sieves Cause Purity Instability?

You trust your molecular sieve[^2]s to do one job: purify gas. But when they fail to perform consistently, your whole operation suffers. It's a hidden weak link causing major problems.

Standard molecular sieve[^2]s often have a wide, inconsistent range of pore sizes[^3]. This is like using a fishing net with random holes. Some impurities pass through, and some desired gas molecules get trapped, leading to unpredictable and fluctuating gas purity.

Let's dive deeper into this. In an air separation unit, the pre-purification system[^7]'s job is to remove water (H₂O) and carbon dioxide (CO₂) from the feed air before it enters the cryogenic section[^8]. If these impurities are not removed, they will freeze and block the main heat exchanger, forcing a plant shutdown. The molecular sieve[^2] is the material that does this removal. However, not all sieves are created equal. Many standard sieves are made with older techniques that result in a chaotic pore structure.

The "Leaky Net" Effect

Think of a standard sieve as a net with holes of all different sizes.

- Holes too big: Some pores are too large. They fail to capture smaller impurity molecules like CO₂, allowing them to slip through and contaminate the process gas.

- Holes too small: Other pores are too small. They unnecessarily trap nitrogen and oxygen molecules, which reduces the overall yield of your plant.

This randomness means the sieve's performance is unreliable. It might work well under one set of conditions but fail when the temperature, pressure, or feed air humidity changes slightly. This is why your gas purity fluctuates.

| Feature | Standard Molecular Sieve | High-Performance Sieve (e.g., 13X-APG[^4]) |

|---|---|---|

| Pore Size Distribution | Wide, Inconsistent | Narrow, Highly Uniform |

| Adsorption Selectivity | Low to Moderate | Very High |

| Purity Fluctuation | High | Minimal to None |

| Process Reliability | Unstable | Highly Stable & Predictable |

How Do High-Performance Sieves Guarantee Stable Gas Purity?

Are you looking for a reliable way to end purity fluctuations for good? Constant adjustments and worries about quality are costly and inefficient. There is a better, more stable solution.

High-performance sieves, like our 13X-APG[^4], are engineered with nano-level, uniform pore channels. These channels are specifically sized to capture CO₂ and water while letting nitrogen and oxygen pass freely. This precision guarantees consistently high gas purity.

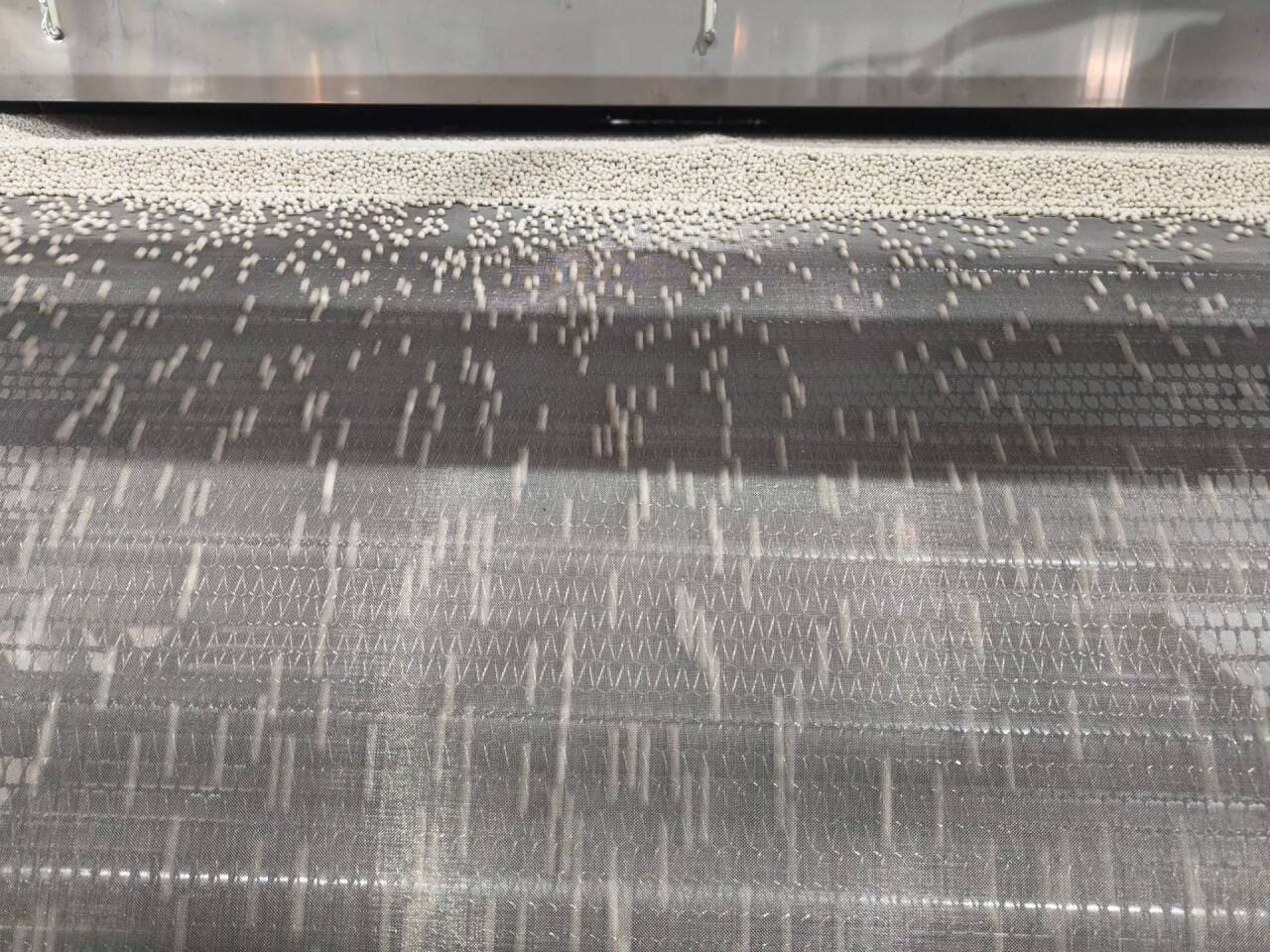

The difference lies in the manufacturing process. At our factory, we use a modern granulator-based forming process[^9], not the old sugar-coating pan method. This allows us to create molecular sieve[^2] beads with incredibly uniform particle size and superior mechanical strength. But the real magic is inside the beads. We engineer the crystal structure to create precise, nano-level channels[^10] throughout the material. Our investment of RMB 8 million in this advanced production line is the foundation of this premium quality.

Like a GPS for Molecules

This advanced structure acts like a navigation system for gas molecules.

- Targeted Capture: The pores of our 13X-APG[^4] sieve are perfectly sized to attract and hold onto CO₂ and H₂O molecules. They are the target, and the sieve is designed to find them.

- Free Passage: At the same time, the larger nitrogen and oxygen molecules don't fit into these pores. They flow past the sieve material freely and move on to the cryogenic section.

There is no guesswork. The separation is clean, efficient, and incredibly consistent. This means the air entering your cold box is always pure, protecting your equipment and guaranteeing the final N₂ and O₂ purity is stable and meets specifications, every single time. As industry experts say, "A superior production line is the foundation of premium products," and our process proves it.

What's the Real Cost of Using the Wrong Molecular Sieve?

Think a cheaper molecular sieve[^2] saves you money upfront? The hidden costs of downtime, lost product, and potential equipment damage can be huge. Let's look at the real financial impact.

Using the wrong sieve leads to fluctuating purity, causing production shutdowns and product rejection. It can also damage sensitive downstream equipment. The total cost of this instability far outweighs any initial savings on a cheaper, lower-quality molecular sieve[^2].

The purchase price of a molecular sieve[^2] is only a small part of its total cost of ownership. I've seen clients try to save a few dollars on a standard sieve, only to pay for it tenfold down the line. The consequences of unstable purification can be severe and create a domino effect of problems across your entire operation.

The Domino Effect of Instability

First, there's the cost of rejected product. If your oxygen or nitrogen purity dips below the required specification, that batch is worthless. But the bigger problem is the risk to your equipment. If CO₂ slips past the sieve bed, it will freeze solid in your main heat exchanger. This creates a blockage, forcing you to shut down the entire plant for a warm-up and thaw cycle, which can take days. That's days of lost production, all because the sieve didn't do its job properly.

I once worked with a client whose plant was experiencing these exact issues, forcing them into costly shutdowns almost weekly. After we analyzed their process and replaced their standard sieve with our 13X-APG[^4], their plant ran for over a year without a single purity-related stop. The return on investment was massive.

| Cost Factor | Standard Sieve | High-Performance Sieve (13X-APG[^4]) |

|---|---|---|

| Initial Purchase | Lower | Higher |

| Production Downtime | Frequent (purity issues, thawing) | Rare |

| Product Rejection Rate | Higher | Negligible |

| Equipment Risk | High (risk of blockage) | Low |

| Total Cost of Ownership | Very High | Lower |

Choosing a high-performance sieve is an investment in reliability and peace of mind. As your partner, our goal is to provide that stability.

Conclusion

Don't let the wrong molecular sieve[^2] compromise your air separation unit. Choosing a high-performance sieve like 13X-APG[^4] is a direct investment in stable purity, production efficiency, and profitability.

[^1]: Understanding the root cause of gas purity fluctuations can help you stabilize your production line and improve efficiency. [^2]: Exploring how molecular sieves function can reveal their critical role in ensuring high-purity gas output. [^3]: Learn how consistent pore sizes in sieves can prevent impurities from contaminating process gas. [^4]: Discover why 13X-APG sieves are preferred for their precision in capturing impurities and ensuring stable gas purity. [^5]: Exploring purification vessels can provide insights into their role in maintaining gas purity. [^6]: Understanding adsorbents can help you choose the right materials for effective gas purification. [^7]: Learn how pre-purification systems remove impurities to prevent plant shutdowns. [^8]: Understanding the cryogenic section can help you see how impurities affect the entire process. [^9]: Discover how modern manufacturing processes create superior molecular sieves with uniform particle sizes. [^10]: Explore how nano-level channels in sieves enhance their ability to capture impurities effectively.