Inconsistent adsorbent performance is hurting your process efficiency and product quality. You suspect material quality, but can't pinpoint the issue. Understanding Loss on Ignition (LOI)[^1] can reveal an adsorbent's true quality.

A low and stable Loss on Ignition (LOI)[^1] indicates higher adsorbent purity[^2] and fewer volatile impurities[^3]. This means you get more active material[^4], leading to better performance, greater process stability, and a higher-quality end product. It's a critical indicator of a superior adsorbent.

This simple metric can tell you so much about the material you are buying. For years, I have seen clients struggle with performance issues that all traced back to this single value. It seems technical, but the concept is straightforward. Let's break down what LOI really means and why it is so important for your business. We will explore how it impacts everything from purity to production costs, helping you make more informed decisions when sourcing critical materials.

What Exactly is Loss on Ignition (LOI)[^1]?

You see "LOI" on a spec sheet but are not sure what it means. Ignoring this term could mean you are buying subpar materials without even knowing it. Let's demystify LOI.

Loss on Ignition (LOI)[^1] is the percentage of weight an adsorbent loses after being heated to a specific high temperature. This lost weight is mainly volatile impurities[^3] like water, organic residues[^5], and carbonates. It is a direct measure of the adsorbent's purity.

In our industry, we often call this "burn-off loss." The idea is simple. We take a sample of the molecular sieve, weigh it precisely, and then heat it in a furnace at a very high temperature for a set amount of time. After it cools, we weigh it again. The difference in weight, expressed as a percentage, is the LOI. This lost mass was not the active adsorbent material. It was made of things that burn off or evaporate. A lower percentage is almost always better. It means the product you received is purer and ready to do its job.

What Components Make Up the "Loss"?

The material that burns off consists of several types of impurities. Each one can negatively affect your process in different ways.

| Impurity Component | Description & Impact |

|---|---|

| Bound Water | This is water trapped within the adsorbent's structure during manufacturing. It takes up space that should be available for adsorbing molecules from your process stream. |

| Hydroxyl Groups (-OH) | These are chemical groups attached to the sieve's surface. They can reduce the sieve's activity and are a sign of incomplete or improper activation during production. |

| Organic Residues | Leftover binders or other organic compounds from the manufacturing process. These can break down at high temperatures and contaminate your final product. |

| Carbonates | Impurities that can decompose at high temperatures, releasing carbon dioxide (CO₂). This can cause unwanted side reactions or pressure issues in sensitive systems. |

Understanding this helps you see that LOI is not just an abstract number. It is a real measure of the "dead weight" you are buying. Our fully automated production lines are designed to minimize these impurities from the very start, ensuring a clean, highly active final product.

How Does a Low LOI Directly Improve Your Application Performance?

Your process requires maximum efficiency, but your adsorbents seem to underperform. This leads to frequent change-outs and increased costs. A low LOI adsorbent directly translates to higher performance and savings.

A low LOI means a higher concentration of active adsorbent material per unit of weight. This provides greater adsorption capacity[^6], leading to longer service life, improved product purity, and more efficient processes. You are paying for performance, not unwanted moisture or fillers.

Think about it this way. When you buy a ton of molecular sieves, a low LOI means more of that ton is actual, working adsorbent. A high LOI means a larger fraction is just inactive material that will not help you. It is like buying concentrated juice versus diluted juice for the same price. You want the one with more of the good stuff. I remember a client in the natural gas industry who switched to our low-LOI 4A molecular sieves. Their dehydration unit's cycle time extended by nearly 20%. That was a significant operational saving that dropped right to their bottom line, all from choosing a purer product.

The Purity-to-Performance Connection

Higher purity directly equals higher performance. Every percentage point of LOI represents space within the adsorbent that is already occupied by impurities. This leaves less room for the molecules you actually want to remove. A lower LOI ensures that the maximum number of pores are open and available from the moment the adsorbent is put into service. This results in a higher dynamic capacity, meaning the sieve can adsorb more contaminants at a faster rate before it becomes saturated.

Impact on Different Applications

The benefit of low LOI is clear across various applications:

- Ethanol Dehydration (3A Molecular Sieve): For producing fuel-grade or pure ethanol, our 3A sieves must remove tiny water molecules without adsorbing the larger ethanol molecules. A low LOI means the sieve has minimal pre-adsorbed water, maximizing its capacity for water from the process stream. This results in higher ethanol purity and less frequent adsorbent regeneration.

- Air Separation Pre-treatment (13X-APG): In air separation[^7] units, our 13X-APG molecular sieve removes CO₂ and water before the air enters the cryogenic section. A low LOI ensures the sieve has the full capacity to handle these impurities, protecting the main unit from freezing and damage. This leads to safer, more reliable plant operation.

- PSA Hydrogen Production (5A Molecular Sieve): During Pressure Swing Adsorption (PSA) for hydrogen purification, our 5A sieves are used to separate impurities like CO, CO₂, and methane. A pure, low-LOI 5A sieve has a cleaner, more defined pore structure. This enhances its selectivity and separation efficiency, yielding higher-purity hydrogen.

Why is a Stable LOI Just as Important as a Low One?

You found a supplier with a low LOI, but batch-to-batch performance is still inconsistent. This unpredictability makes it impossible to optimize your process, causing constant adjustments and headaches. The key is stability.

A stable LOI from batch to batch guarantees consistent product quality and predictable performance. It means the manufacturing process is highly controlled and reliable. This stability allows you to standardize your operations, reduce process adjustments, and trust that every shipment will perform the same.

A few years ago, a distributor told me they lost a major client. The reason was that their previous supplier's molecular sieve varied so much in quality from one container to the next. Their client's process was constantly out of spec. After they switched to us, they rebuilt that trust. They knew that every shipment would have the same low and stable LOI, delivering the same results, container after container. That is the power of stability. It builds confidence and makes you a reliable partner for your own customers.

The Hidden Cost of Inconsistency

When LOI varies between batches, your process becomes a moving target.

- Constant Recalibration: Your engineers have to spend valuable time adjusting cycle times, regeneration temperatures, and flow rates to compensate for the adsorbent's changing capacity.

- Unpredictable Service Life: You cannot accurately predict when an adsorbent bed will need to be changed out. This can lead to either premature, wasteful change-outs or, even worse, unexpected breakthroughs of contaminants that ruin your final product.

- Risk of Off-Spec Product: An underperforming batch of adsorbent can lead directly to products that fail to meet quality standards. This results in costly rework, scrap, or even customer claims.

How We Achieve Unmatched Stability

Consistency does not happen by accident. It is the result of investment and process control.

- Advanced Production Line: Our RMB 8 million, fully automated production line is the cornerstone of our quality. It minimizes human error and ensures every step of the process is executed with precision.

- Superior Forming Process: We use a granulator-based forming process, not the older "sugar-coating pan" method. This results in beads with a more uniform size, higher mechanical strength, and lower dust. This physical integrity contributes to a more stable chemical composition, including a stable LOI.

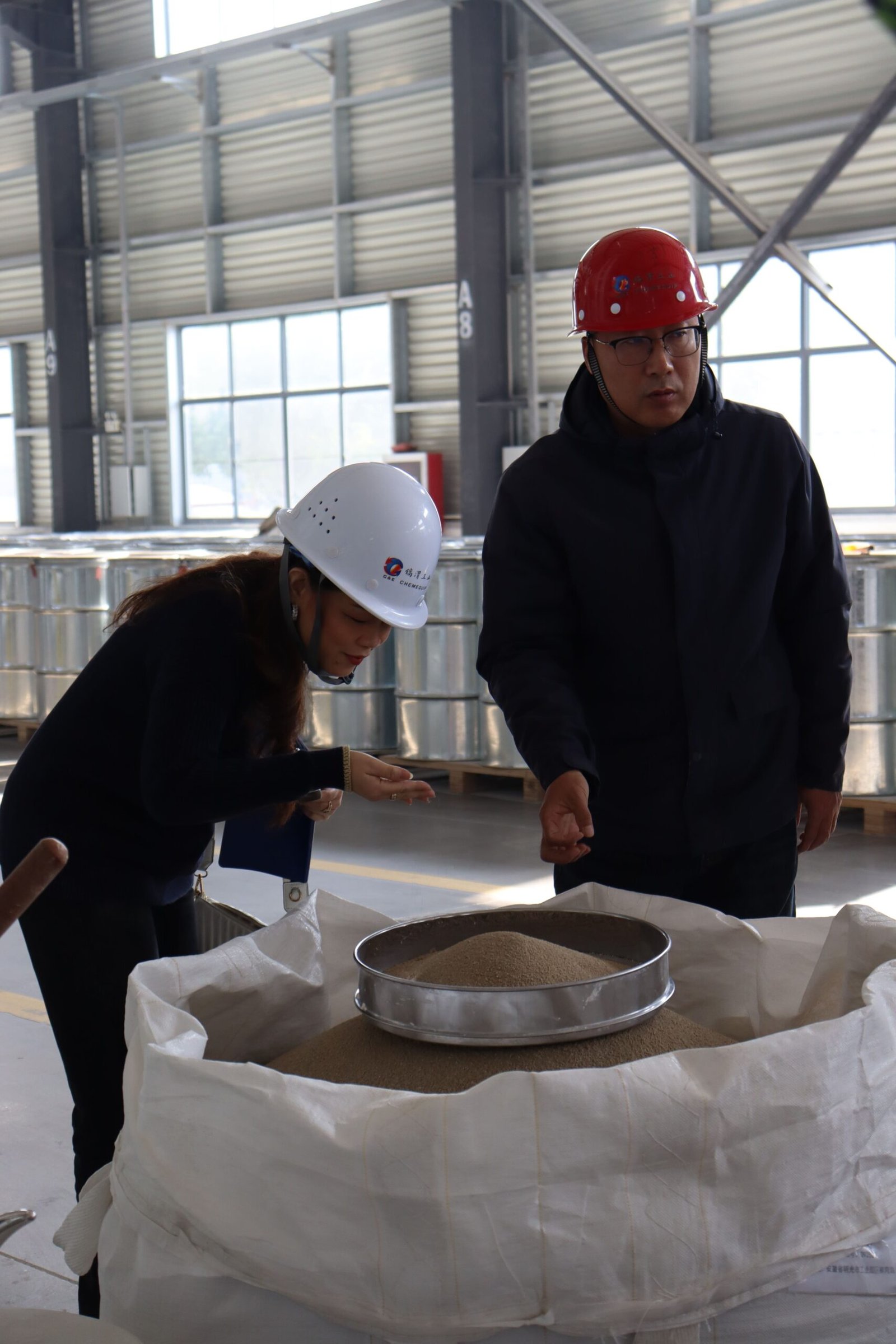

- Rigorous Quality Control: We test raw materials and finished products relentlessly. LOI is one of the key parameters we monitor for every single batch that leaves our factory. As an industry expert once told me during a tour, "A superior production line is the foundation of premium products." We live by that philosophy.

How Can You Identify a High-Quality Adsorbent Using LOI?

You are evaluating several suppliers, and their spec sheets look similar. How do you choose the best partner and avoid a costly mistake based on incomplete data? Asking the right questions about LOI can help.

To identify a high-quality adsorbent, do not just look at a single LOI value. Ask for the typical LOI range and review Certificates of Analysis from multiple batches to verify stability. A truly transparent and capable supplier will readily provide this data.

A good spec sheet is a starting point, but it does not tell the whole story. The best suppliers are not afraid to prove their consistency. When a potential partner is open and provides data to back up their claims, it is a strong sign that you are dealing with a professional and reliable manufacturer. We welcome these questions because we are proud of the stability our production process delivers. We believe that transparency is key to building long-term partnerships.

What to Ask Your Potential Supplier

When you are qualifying a new molecular sieve supplier, digging deeper into their LOI data can be very revealing. Here are some key questions to ask:

| Question for Supplier | Why It Matters |

|---|---|

| "What is your typical LOI range for this product?" | A single number can be an ideal target, but the range tells you about their process control. A narrow range (e.g., 1.0% - 1.5%) indicates high stability. A wide range (e.g., 1.0% - 3.0%) is a red flag for inconsistency. |

| "Can you provide COAs from the last 3-5 production lots?" | This is the most important request. It allows you to see their actual, real-world consistency over time. A single good COA can be a fluke; five good ones in a row show true process mastery. |

| "What is your testing protocol for LOI (temperature and duration)?" | This shows if they follow industry standards. Inconsistent testing methods can produce misleading results. Knowing their protocol helps you compare their product apples-to-apples with others. |

| "How does your production process ensure a low and stable LOI?" | A confident, high-quality supplier will be happy to explain their technology. They should be able to talk about their raw material control, activation process, and forming technology, just as we can point to our automated line and granulator process. |

We encourage factory visits so you can see our top-tier production line for yourself. Seeing is believing, and we stand behind the quality that our advanced manufacturing facility produces.

Conclusion

In short, a low and stable Loss on Ignition is not just a number on a spec sheet. It is a direct indicator of adsorbent purity[^2], performance, and manufacturing consistency.

[^1]: Understanding LOI is crucial for evaluating adsorbent quality and ensuring optimal process efficiency. [^2]: Exploring adsorbent purity can help you improve product quality and reduce operational costs. [^3]: Learn about volatile impurities to better understand their impact on adsorbent performance. [^4]: Discover the importance of active material for enhancing adsorbent efficiency and effectiveness. [^5]: Explore the effects of organic residues to ensure you choose the best adsorbent for your needs. [^6]: Understanding adsorption capacity is key to selecting the right adsorbent for your application. [^7]: Learn how LOI impacts air separation processes for improved operational reliability.