Is your adsorbent creating dust and clogging your filters? This increases maintenance costs and downtime. Choosing a low-attrition adsorbent is the key to a clean, efficient system.

Excessive adsorbent attrition creates dust that contaminates your compressed air, clogs downstream equipment, and shortens the adsorbent's lifespan. This leads to higher operational costs and reduced system reliability. A low-attrition molecular sieve is crucial for maintaining air quality and efficiency.

This dust problem is more than just a minor annoyance. It is a clear sign of a deeper issue with your adsorbent's quality. But how can you be sure your adsorbent is up to the task? Let's explore what attrition really means and how we measure it to guarantee performance. Understanding this is the first step toward a more reliable and cost-effective operation for your business.

How is the Adsorbent Attrition Rate Actually Measured?

Are you unsure if your adsorbent is truly durable? This uncertainty can lead to unexpected system failures. We use precise testing to provide the quality assurance you need for peace of mind.

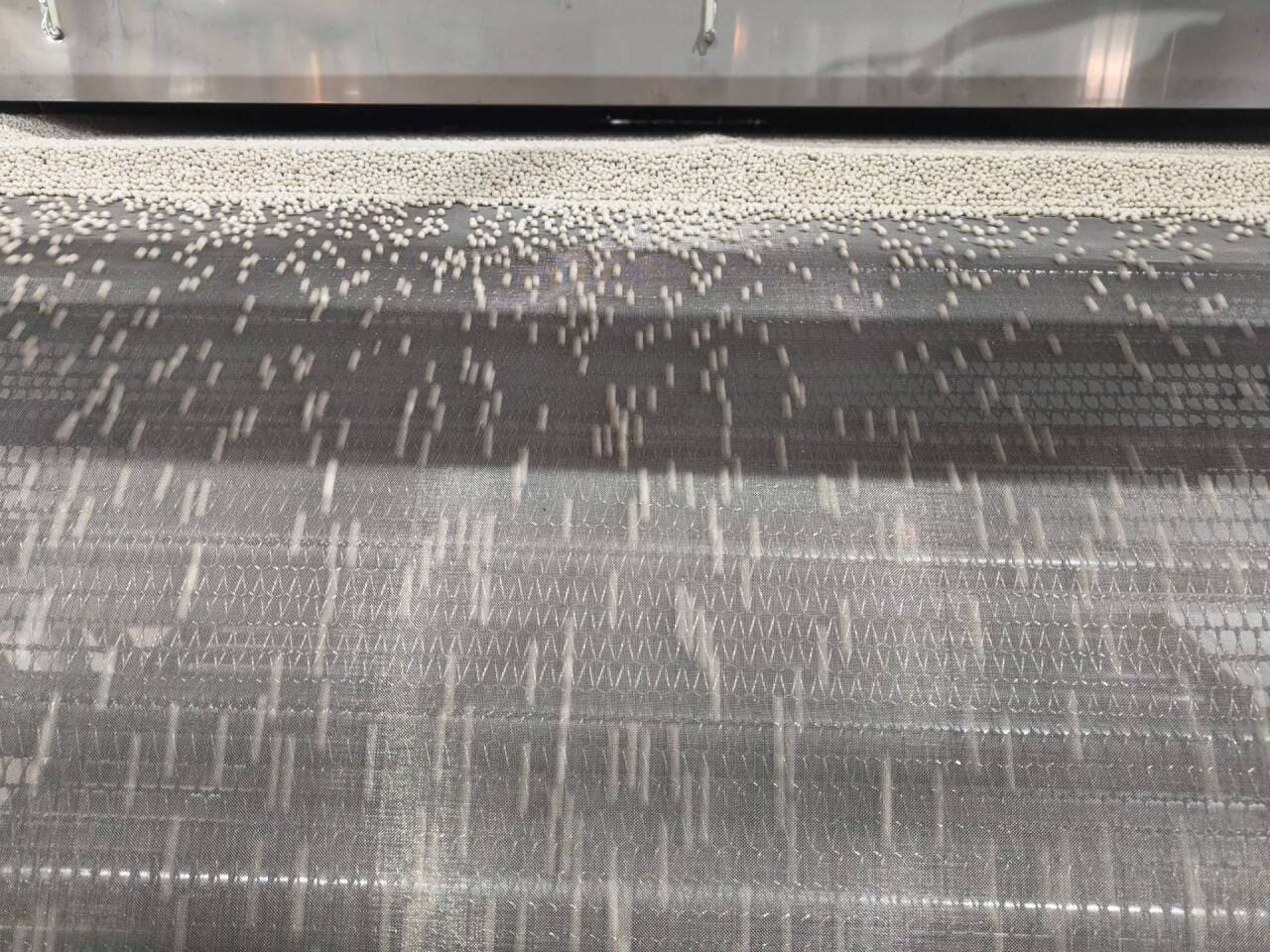

We measure attrition by tumbling a dried molecular sieve sample in a specialized drum at a set speed and time. Afterward, we sieve the sample to separate and weigh the generated dust. A lower dust weight indicates a lower, more desirable attrition rate.

I often wish I could bring all our clients into our lab to see this process firsthand. It's a critical part of our quality control. The test reveals the adsorbent's ability to resist wear and tear.

The process is straightforward but requires precision.

- Sample Preparation: We start by taking a representative sample of molecular sieve beads and drying them completely to ensure moisture doesn't affect the result.

- The Test: We place the dried sample into the drum of a multi-functional attrition tester. We then set a specific rotational speed and duration, which simulates the mechanical stress the beads will face inside an industrial air dryer tower.

- Analysis: Once the machine stops, we carefully remove the sample. We then use a fine-mesh sieve to separate the intact beads from the fine powder, or "dust," that has been generated. We weigh this dust.

The result is simple: the less dust, the lower the attrition rate and the higher the mechanical strength of the adsorbent. A low number here is a powerful indicator of a high-quality product that will last longer and perform better in your system. This isn't just a lab test; it's your guarantee against premature failure and excessive maintenance costs.

What are the Direct Consequences of High Attrition in Compressed Air Systems?

Are you seeing dust in your air lines? This contamination can damage sensitive equipment. A high-quality adsorbent prevents this, protecting your investment and ensuring smooth operations for your customers.

High attrition leads to several problems. It creates dust that can block valves and filters, contaminate the final product, and reduce the adsorbent's effective surface area. This forces more frequent change-outs and increases maintenance costs, directly impacting your bottom line.

When an adsorbent with a high attrition rate breaks down, the consequences ripple through the entire compressed air system. It’s not just a mess to clean up; it's a direct threat to your operational efficiency and profitability. As a partner to global brands and distributors, I've seen how these issues can impact a business.

Increased Maintenance and Downtime

The most immediate problem is dust. This fine powder travels downstream from the dryer. It clogs after-filters, requiring them to be cleaned or replaced more often. If the dust gets past the filters, it can gum up the internal workings of pneumatic valves, cylinders, and tools. This leads to equipment malfunction, production stoppages, and costly repairs. Every hour of unplanned downtime is lost revenue.

Reduced Adsorbent Performance and Lifespan

Attrition physically wears down the adsorbent beads.

- Powdering: The beads become smaller, creating fine dust. This dust can pack together, increasing the pressure drop across the dryer bed. Your compressor has to work harder to push air through, consuming more energy.

- Reduced Capacity: As the beads break down, their effective mass and surface area for adsorption decrease. The bed can no longer hold as much moisture, meaning the adsorbent needs to be replaced much sooner than expected. This cycle of frequent, costly change-outs is a major drain on resources.

| Problem Caused by High Attrition | Financial and Operational Impact |

|---|---|

| Clogged Downstream Filters | Increased cost of replacement filters; higher labor costs for maintenance. |

| Damaged Pneumatic Equipment | Production downtime; expensive repair or replacement of valves and tools. |

| Increased Pressure Drop | Higher energy consumption from the air compressor; reduced system efficiency. |

| Premature Adsorbent Failure | Frequent and costly adsorbent replacement; increased labor and disposal costs. |

Ultimately, a "cheaper" adsorbent with high attrition costs you far more in the long run. It's an issue we help our partners avoid by focusing on superior mechanical strength from the start.

How Does Choosing the Right Manufacturing Process Reduce Attrition?

Are you tired of adsorbents that crumble under pressure? This leads to constant replacements and system problems. Our advanced manufacturing process creates a stronger, more reliable product you can trust.

The manufacturing process is key. We use a granulator-based forming process, not the older sugar-coating pan method. This results in molecular sieve beads with more uniform size, higher mechanical strength, and significantly lower dust generation, ensuring a low attrition rate.

The secret to a low-attrition molecular sieve isn't a secret at all; it's about the investment in a superior production line and process. For over 20 years in this industry, I have seen the difference firsthand. You simply cannot produce a premium product without a premium manufacturing foundation.

The Old Way: Sugar-Coating Pan Process

Many manufacturers still use an older, less effective method that resembles making candy. In a large, rotating "sugar-coating pan," a base material is sprayed with a binder and raw molecular sieve powder. The process builds up the bead layer by layer. The problem is that these layers are not strongly bonded. The outer shell is fragile and easily flakes off under the mechanical and thermal stress inside a dryer tower. This is a primary source of adsorbent dust and high attrition.

Our Modern Method: Granulator-Based Forming

We took a different path by investing RMB 8 million in a fully automated, granulator-based production line. Instead of coating a core, our process builds a solid, homogenous bead from the inside out. The raw materials are mixed and formed under pressure into a uniform, dense sphere. This creates a product with exceptional mechanical strength from its core to its surface. There are no weak outer layers to break off. As one industry expert noted after reviewing our facility, "A superior production line is the foundation of premium products."

This advanced process delivers tangible benefits for our OEM/ODM partners and distributors:

- Higher Mechanical Strength: Drastically reduces dust generation and attrition.

- More Uniform Particle Size: Ensures consistent airflow and prevents pressure drop issues.

- More Stable Product Quality: Automation removes human error, delivering reliable performance batch after batch.

This commitment to manufacturing excellence is why we can confidently supply products that lower operating costs and enhance system reliability for our clients worldwide.

Conclusion

A low-attrition adsorbent is not a luxury. It is essential for reducing operating costs, protecting your equipment, and ensuring the long-term reliability of your compressed air system.