I once faced a factory shutdown because of moisture contamination. I grew anxious. Then I discovered molecular sieves. They saved my entire operation.

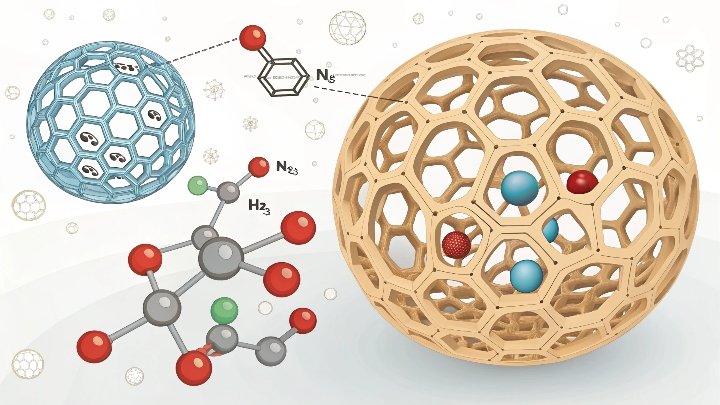

The term “molecular sieve” describes materials that act as tiny filters. They allow certain molecules to pass or be adsorbed, while blocking others based on size, shape, or polarity.

I remember the first time I heard someone mention “molecular sieve.” I was curious about why it carried that name. I sought answers from experts in the adsorbent field and realized it was more than a label. It was a practical description of how these materials work at the molecular level. I kept researching, learning, and testing their abilities in industrial processes. Then I decided to write down my findings, so others could understand these remarkable materials and use them to solve pressing problems in manufacturing, air separation, and beyond. Now I want to share these insights, starting with the core explanation of what a molecular sieve is.

What is meant by molecular sieve?

I remember when I held my first batch of molecular sieve beads. I felt like I had discovered a secret weapon.

A molecular sieve is a substance with small pores that trap or separate molecules by size or shape. This ensures targeted adsorption in many industrial applications.

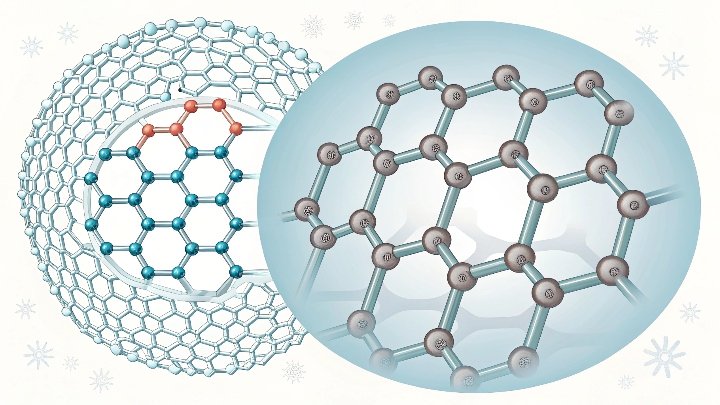

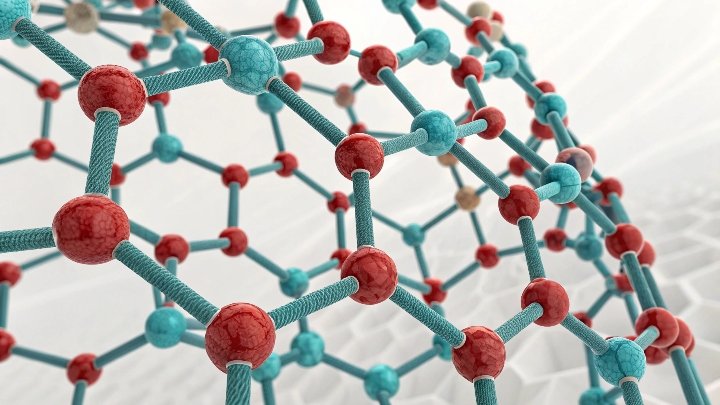

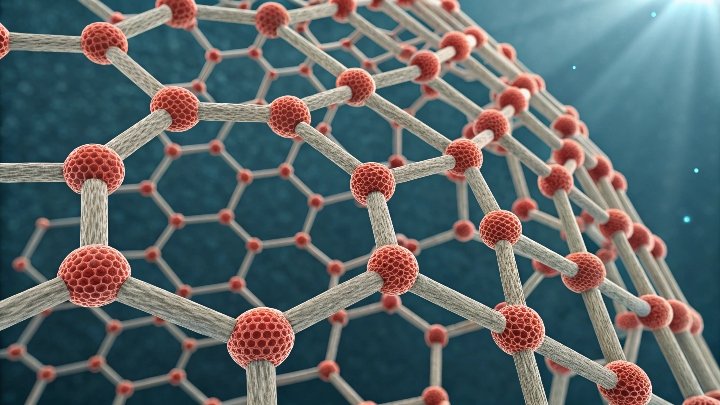

I see molecular sieves as guardians of quality. They protect products and processes from unwanted contaminants. The name “molecular sieve” comes from their function: they have tiny pores that work like sieves at the molecular scale. When I first delved into their structure, I discovered that most molecular sieves have crystalline frameworks, such as zeolites. These frameworks contain uniform channels and cavities. The size of these channels matches specific molecular diameters. This match or mismatch allows certain molecules to enter while preventing others from doing so. It sounds simple, yet it is vital in many industrial fields.

I learned that one key feature is selectivity. The sieve’s pore size determines which molecules pass through. This helps in moisture removal, gas separation, and purifying chemicals. I have watched engineers use these sieves to reduce water vapor in compressed air and to refine chemical processes. When molecules are too large to pass through the pores, they remain outside. Smaller molecules can slip inside the structure and bond via various forces, like Van der Waals interactions. The differences in shape and polarity can also play a role in deciding which molecules adsorb more strongly. That targeted nature saves resources and improves product purity.

One of my first experiences with molecular sieves was in a drying application. I saw them remove moisture from ethanol, ensuring a pure final product. That example made me realize how powerful these materials could be in many manufacturing steps. From my perspective, if you have a problem with unwanted molecules in any process stream—like water or other contaminants—a molecular sieve could be a solution. These materials are now a major factor in gas refining, controlling humidity, and even protecting expensive electronics from moisture damage. I have learned that molecular sieves are not just ordinary adsorbents. They hold a systematic approach to molecular-level filtering that can change how we look at product quality and process efficiency.

Pore Sizes and Selectivity

| Pore Size (Å) | Common Applications | Typical Molecules Adsorbed |

|---|---|---|

| 3Å | Drying of polar compounds | Water (H2O) |

| 4Å | General moisture removal | Water, NH3, small molecules |

| 5Å | Separation of normal paraffins | Straight-chain hydrocarbons |

| 13X | Air separation, gas purification | Water, CO2, H2S, other larger molecules |

I keep this table in mind when I explain the concept to new team members. It shows how pore size influences adsorption choices. It also highlights how easy it is to tailor these materials for different tasks. I believe a good understanding of these differences helps us make informed decisions about which molecular sieve is best for a given process.

What is the difference between molecular sieve and silica gel?

I once confused silica gel with molecular sieves. My project suffered. Then I researched further, which changed my perspective on adsorbents.

Molecular sieve uses precise pore sizes to adsorb specific molecules. Silica gel uses broader pore structures that trap moisture but lack the strict size-based selectivity of a sieve.

When I tried to use silica gel in a specialized gas drying process, I found out it was not as effective as a molecular sieve. Silica gel is a common desiccant. I have used it in packaging to keep products dry or to preserve goods from moisture. Silica gel has random pore sizes and a high surface area. This means it can adsorb a wide range of substances, especially water vapor. However, it does not offer the precise molecular screening that a molecular sieve can provide.

I remember a specific comparison test. I placed silica gel and a 4Å molecular sieve side by side. Both were tasked with removing moisture from an ethanol stream. The silica gel adsorbed moisture at first, but it quickly reached saturation and did not create a very low moisture level. The molecular sieve, on the other hand, continued to remove water to a much lower level, allowing the ethanol to meet stringent purity standards. That difference was huge for me. It revealed how pore structure and the uniformity of channels matter so much in advanced manufacturing.

Another aspect I learned is regeneration. Silica gel can be regenerated if heated to drive off adsorbed water. Molecular sieves can also be regenerated with heat or vacuum, but they often require more specific conditions due to their strong adsorption of certain molecules. However, the payoff is greater selectivity and stronger adsorption capacity in many critical processes. This difference means that in some industrial applications, I might be able to use silica gel if the requirements are not very strict. But if I need very low moisture levels or if I need to remove molecules that fit a certain shape, I will choose a molecular sieve.

I also discovered that silica gel is typically less expensive. For simple tasks like basic drying in consumer applications, silica gel might be enough. But for processes involving chemical separations, high-purity gas streams, or critical moisture removal, molecular sieves often provide better results. I once spoke with a design engineer who explained that each adsorbent has its place. The key is understanding the role of pore size and what “molecular sieve” implies about targeted performance. That knowledge has helped me guide clients toward the right adsorbent choice, saving time and resources.

Key Differences in Adsorption

| Property | Molecular Sieve | Silica Gel |

|---|---|---|

| Pore Structure | Uniform, fixed size | Random, varied sizes |

| Selectivity | Very selective by size/polarity | Broad moisture adsorption, less selective |

| Regeneration | Requires controlled heat/vacuum | Easier, but less robust |

| Typical Use Cases | High-purity processes, gas refining | Basic moisture control, packaging |

I find that understanding these differences is crucial for anyone working with advanced separation tasks. I made mistakes early in my career by using the wrong adsorbent for the job. Now I always start by clarifying what molecules I need to remove or retain. That approach usually leads me to the right type of adsorbent, whether it is silica gel, a specialized molecular sieve, or something else.

Is silica a molecular sieve?

I was once asked if silica gel could be seen as a molecular sieve. I paused, recalling my past confusion.

Silica gel is not typically considered a molecular sieve. Although it adsorbs moisture, it lacks the strict pore size uniformity found in true molecular sieves.

I want to clarify why silica gel is not a true molecular sieve. A molecular sieve offers rigid and well-defined pores that can separate molecules based on tiny differences in size, shape, and polarity. In contrast, silica gel has a more amorphous and random pore structure. This difference means silica gel does not “sift” molecules with the same precision. It can remove water vapor by capillary condensation, but it does not function like a strict filter at the molecular scale.

I often compare molecular sieves to a lock and key mechanism. Each molecular sieve has a specific pore size that acts like a lock, only allowing keys (molecules) of a particular size or shape to enter. This process is systematic and consistent. Silica gel is more like a sponge with many cavities that vary in size. It can hold water, but it is not carefully designed to screen molecules by exact diameter or shape. That is why I do not see silica gel used for specialized separations like removing carbon dioxide from gas streams or separating normal paraffins from branched ones. Those tasks need the precise control offered by molecular sieves.

I recall a scenario where I needed to remove a specific molecule from a mixture, while leaving others behind. I talked to a researcher who recommended a zeolite-based molecular sieve with a pore size of 5Å. This sieve allowed only the normal paraffins to be adsorbed, while branched isomers passed through. Silica gel did not work for this job. It did not have uniform pores, so it adsorbed a mixture of many molecules, leading to an inconsistent separation. That real-world experience convinced me that the fundamental difference in pore structure is the deciding factor.

One thing I try to emphasize is that adsorbents all have strengths and weaknesses. Silica gel is effective and affordable for moisture control in packaging or storage. It can keep your electronics or food products fresh and dry. But if you need a precise separation at the molecular level, you turn to a molecular sieve. That choice stems from the specialized design of the sieve. I believe it is important to make sure people know the difference, so they can apply each adsorbent in the right place. I had to learn this through trial and error. Now I want to save others time by sharing that experience.

Silica Gel vs. True Molecular Sieves

| Aspect | Silica Gel | True Molecular Sieves |

|---|---|---|

| Pore Uniformity | Amorphous, varied | Highly uniform, crystalline |

| Adsorption Selectivity | Broader, less precise | Very specific and selective |

| Typical Applications | Simple drying tasks | Advanced separation processes |

| Structure and Composition | Mostly amorphous SiO2 | Crystalline framework (e.g. zeolite) |

I hope this table makes it clearer why we do not call silica gel a molecular sieve. The mismatch in pore uniformity and selectivity is the biggest reason. I have seen confusion in product descriptions or casual conversations, but the science is straightforward. Silica gel can dry the air in a package. A molecular sieve can separate molecules of similar sizes with high precision. That difference is the key to choosing the right adsorbent.

Conclusion

I find molecular sieves special because they screen molecules precisely, making them indispensable for many advanced industrial tasks.