Do you want to remove moisture with pinpoint accuracy but do not know where to start? This issue can feel overwhelming. I have felt the same frustration.

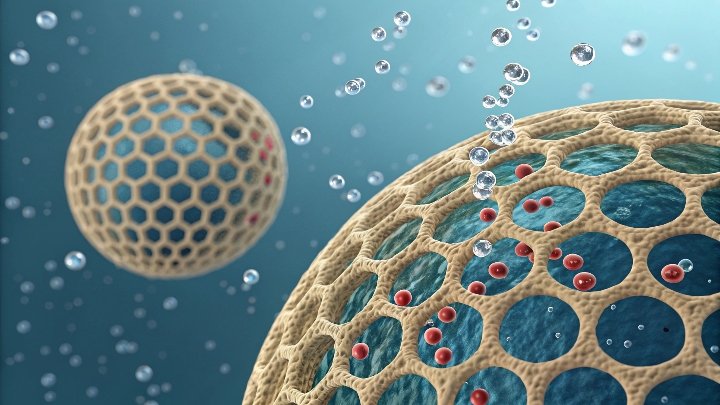

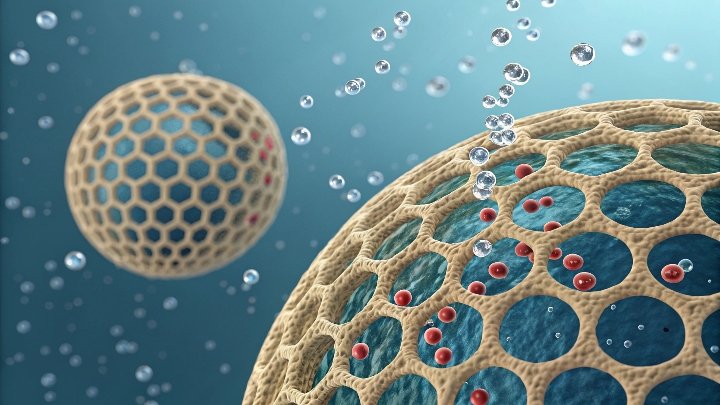

Molecular sieves are the top solution for water removal. Their tiny pores capture water molecules. They ignore bigger molecules. This targeted approach means high efficiency. These sieves also resist many contaminants, so they keep their performance for a long time.

At first, I was unsure why molecular sieves are so special. Then I realized they have a unique pore structure that absorbs water selectively. This design makes them stand out. They do not just dry the environment. They also support sustainability. Now, let’s see how they work.

I am fascinated by the "intelligent screening" of molecular sieves!

Have you ever wondered how sieves can act like tiny guards against unwanted moisture? I used to question if there was a secret behind their precise absorption.

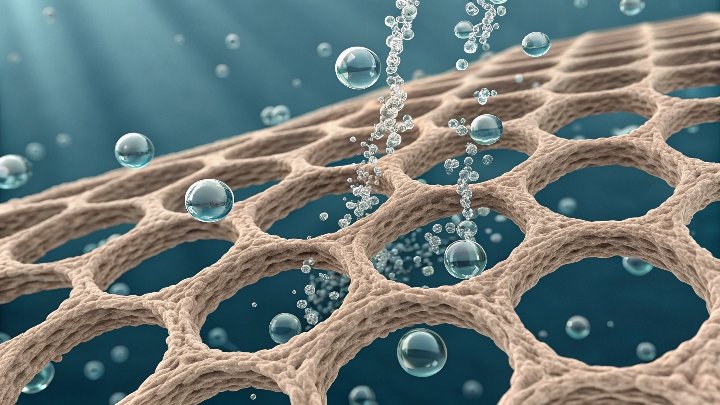

They have uniform pores that screen molecules by size. Water molecules fit these pores, so they get trapped. Larger molecules remain free. This simple mechanism is why I call it “intelligent screening.” It focuses on moisture and leaves the rest alone.

Molecular sieves have uniform pore sizes that control which molecules enter. This uniformity is important for water removal. If a molecule is smaller or equal to the pore diameter, it gets adsorbed. If it is larger, it cannot pass. That is the simple principle behind their "intelligent screening." I remember when I first toured a lab that tested adsorbents. The researcher showed me how a small sample of molecular sieve could dry a liquid mixture within minutes. I was amazed by the precision. No other common desiccant matched that speed.

The intelligent aspect also includes how molecular sieves ignore larger molecules. They only adsorb water, leaving other compounds mostly untouched. This means that industrial processes remain stable. I have seen this in natural gas treatment and in pharmaceutical production. In both cases, you want to remove only water while keeping the main product pure.

When we look at the consistency of pore sizes, we see a strong advantage over other drying methods. Other materials may remove water, but they also adsorb unwanted substances. That can disrupt the final product. Molecular sieves simplify the process with a targeted approach.

Below is a brief table that shows some key features and benefits:

| Feature | Benefit |

|---|---|

| Uniform pore structure | Accurate water capture |

| Selective adsorption | Protects product purity |

| Stable performance | Consistent drying over many cycles |

| High capacity | Reduces process downtime |

These points highlight why I admire this “intelligent screening.” It is not magic. It is science and practical design.

Renewability: the "environmental philosophy" of molecular sieves!

Have you ever thrown away a used desiccant and wondered if there was a better way? I used to feel guilty about contributing more waste.

Molecular sieves stand out because we can regenerate them. We can heat them to remove adsorbed water, and then reuse them. This reduces waste. It also saves money. That is their core environmental advantage.

Many people do not realize how easy it is to regenerate molecular sieves. The process usually involves heating the sieve bed or applying a vacuum to draw out the adsorbed water. This means we can use the same sieve multiple times. That helps reduce operating costs and the environmental footprint.

I remember a project where we wanted a greener drying method. Traditional materials would work once. Then we would have to discard them. But molecular sieves let us reuse the same batch for months. We needed only to heat them in a small oven at intervals. That simple step kept them effective for a very long time.

This renewability reflects an “environmental philosophy.” We do not have to mine new desiccants or produce more synthetic materials every time. We can rely on the same molecular sieve. This approach is more sustainable. It also reduces the carbon footprint of large-scale manufacturing and processing.

Below is a simple table that shows why renewability matters:

| Aspect | Impact |

|---|---|

| Reusability | Less waste, cost savings |

| Lower consumption | Fewer raw materials needed |

| Efficient heating | Quick regeneration |

| Consistent quality | Maintains stable performance |

Because we can reuse molecular sieves, we generate less waste. We also reduce costs. I like that it aligns with a respect for nature. In my work, I have seen how this renewability improves both the bottom line and the environment.

The "ultimate challenge" of molecular sieves: close to absolute dryness

Do you want to push dryness to an extreme level? I used to doubt that near-zero moisture levels were possible. But molecular sieves opened my eyes.

These sieves can achieve dryness levels that approach absolute. They remove water down to parts per million levels. That is why industries like electronics and pharmaceuticals rely on them. They do not leave room for moisture to hide. That is how they set the bar so high.

Achieving near-absolute dryness was once a dream for many industries. Electronics manufacturers faced circuit board damage if moisture snuck into delicate components. Pharmaceutical labs worried about water spoiling sensitive chemicals. I recall a time when I worked with a team handling high-grade solvents. Even the tiniest bit of water caused unwanted reactions. That was when I discovered the power of molecular sieves.

Molecular sieves can bring moisture content down to the parts per million range. This is critical for processes that demand extreme dryness. The secret lies in the tight pore openings and their strong affinity for water molecules. Once those molecules enter the pores, they stay put until we regenerate the sieve. This is especially useful in continuous operations where stable dryness is a top priority.

I have seen how molecular sieves can outperform other drying methods like silica gel. Silica gel works well, but it rarely reaches the same low moisture levels as molecular sieves. That difference can mean the success or failure of a sensitive operation. Also, sieves have a longer lifespan when you regenerate them correctly.

Here is a quick look at different dryness ranges:

| Desiccant | Typical Moisture Level (ppm) |

|---|---|

| Silica Gel | ~100 to 500 |

| Activated Alumina | ~10 to 100 |

| Molecular Sieve | <1 to 10 |

These values can vary, but molecular sieves often deliver the lowest levels. That is why I trust them for ultimate dryness. When I need to ensure no moisture remains, I rely on this robust adsorbent.

Conclusion

Molecular sieves offer precise water removal, renewability, and extreme dryness. They represent the harmony of technology and nature, driving us toward a cleaner, drier future.